Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Good anti-stickiness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

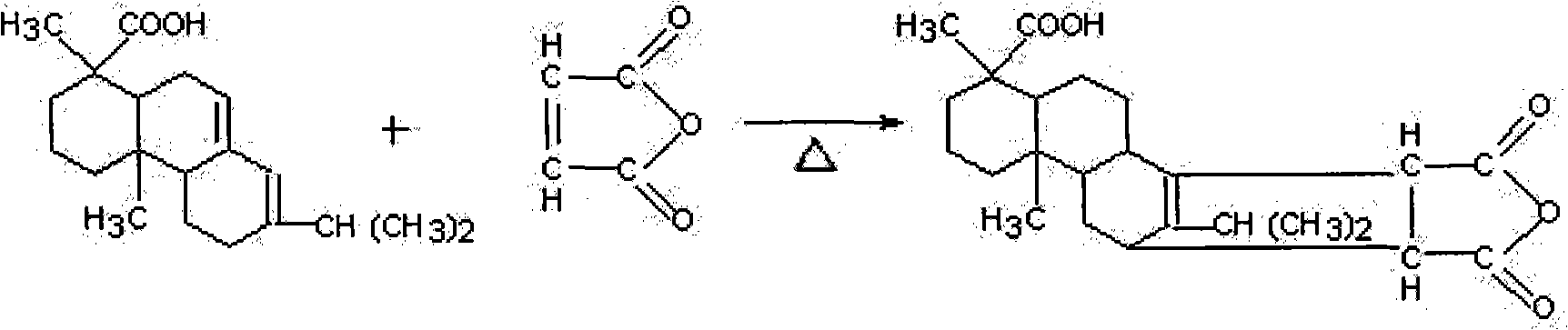

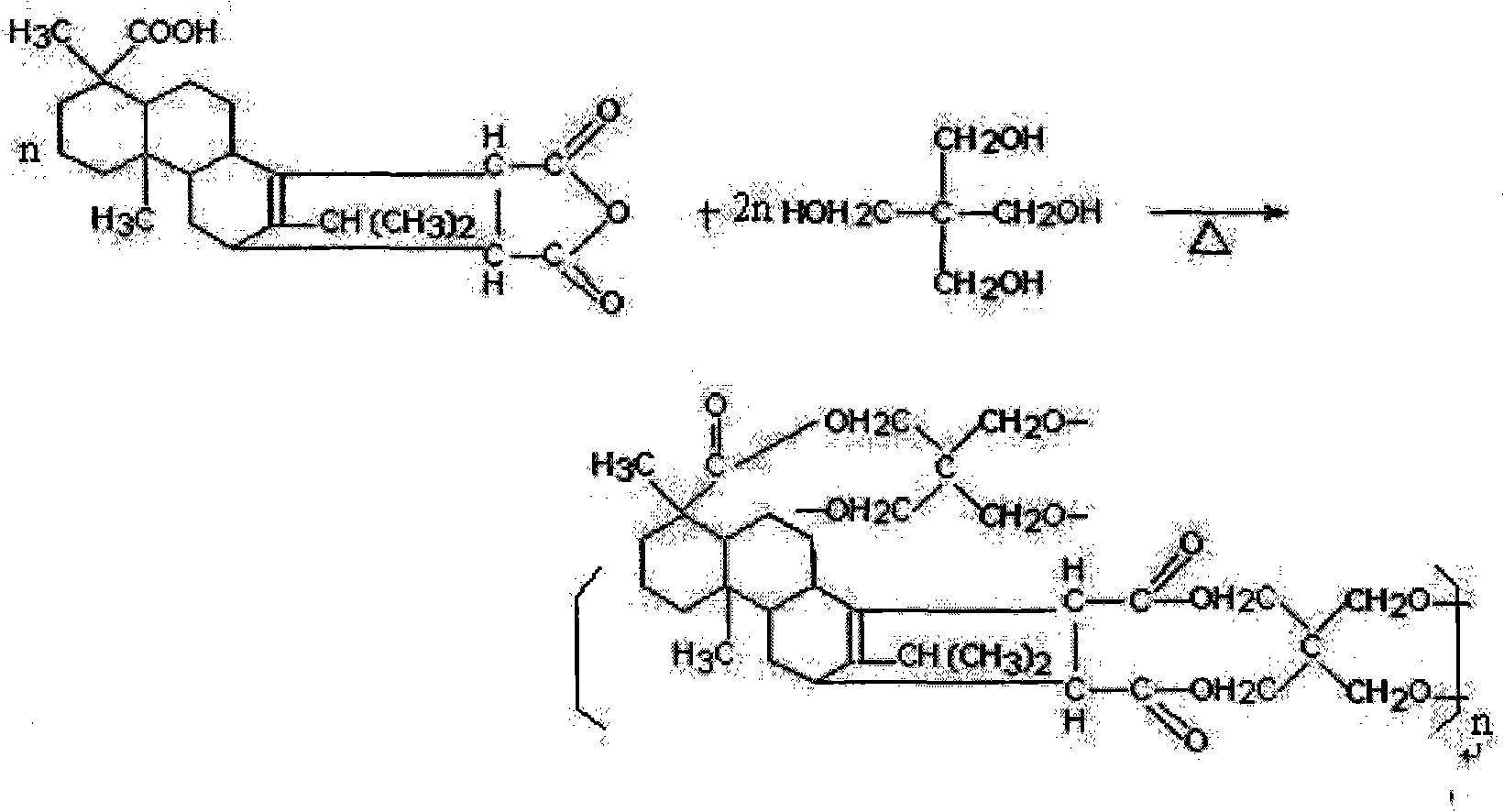

Production method of abietic maleic anhydride resin

InactiveCN102010503AExemption from releaseProtect physical and mental healthInksNatural resin chemical modificationSolubilityReaction temperature

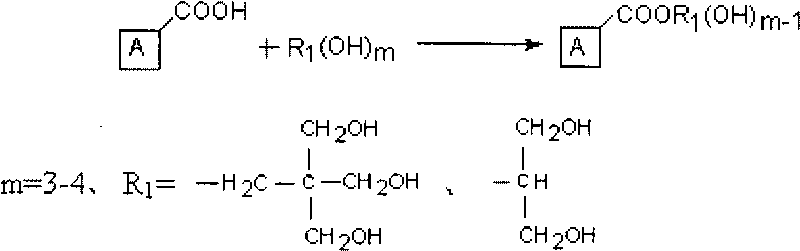

The invention relates to a production method of abietic maleic anhydride resin, comprising the following two reaction steps of: 1, carrying out addition reaction on abietyl and maleic anhydride to generate an abietic maleic anhydride addition product; and 2, carrying out esterification reaction on the abietic maleic anhydride addition product and pentaerythritol to generate the abietic maleic anhydride resin. The production method is easy and convenient to operate, has the advantages of large temperature control range, high operability, small investment and stable product quality and is a method suitable for industrialized production; in the production method, appropriate process conditions including raw material proportion, reaction temperature, reaction time, catalysts, and the like, are adopted, thereby the acid value and the molecular weight range of a resin product can be effectively controlled; in addition, the resin product obtained with the production method has higher acid value of 150-170 mg KOH / g, reasonable softening point at 140-155 DEG C and good water solubility and is suitable for producing water-based ink, and a formed coating film has toughness and better after-tackiness resistance, water resistance and alkali resistance.

Owner:上海华谊精细化工有限公司上海南大化工厂

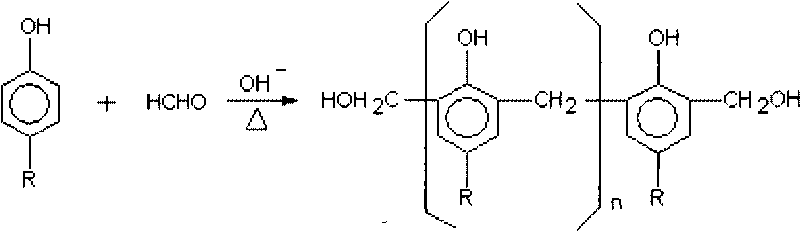

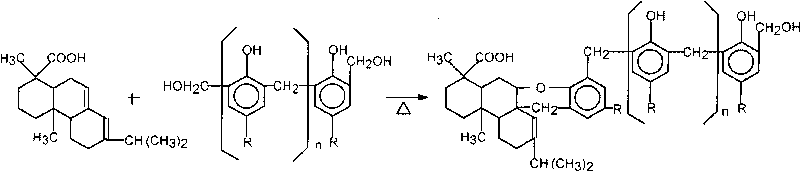

Preparation method of rosin modified phenolic resin

The invention relates to a preparation method of a rosin modified phenolic resin. The method comprises the following three steps of reactions: 1. performing condensation of tert-butylphenol, bisphenol A, tung oil and solid formaldehyde under the action of catalyst magnesium acetate and lime to generate polymer of hydroxymethyl tert-butylphenol; 2. performing an addition reaction with rosin to generate an addition product; and 3. performing esterification of the addition product, pentaerythritol and glycerin under the action of catalyst zinc chloride to generate the rosin modified phenolic resin. The preparation method adopts proper raw material proportioning, reaction temperature, reaction time, catalyst and other technical conditions, thus during the production process, the resin viscosity can be effectively controlled, and the operation is simple and flexible and has good effect. The quality of the product is increased, the oil solubility of resin is good, the oil medium viscosity is high, the normal heptane capacity is 4.5ml / g or more; and the prepared paint film ink has good water resistance and alkali resistance, high hardness, excellent anti-after-binding performance, quick-drying performance, lightness and strong adhesive force. Therefore, the preparation method of the invention is applicable to industrial production.

Owner:SHANGHAI HUAYI FINE CHEM CO LTD

Waterborne heat insulation waterproof coating material

InactiveCN101298528AImprove waterproof and heat insulation effectIncreased durabilityFireproof paintsAntifouling/underwater paintsWater basedSoft water

The invention discloses a water-based heat insulation and waterproof coating which is characterized in that the coating consists of materials with following weight percentage (two components), wherein, component A: 1-20 percent of soft water, 0.1-0.3 percent of hydroxyethyl cellulose, 0.1-0.2 percent of preservative, 0.1-0.4 percent of anti-mildew agent, 0.1-0.2 percent of organic amine, 0.1-0.3 percent of amine salt dispersant, 0.01-0.18 percent of defoamer, 1-4 percent of ethylene glycol, 80-93 percent of good alkali resistant and high elastic pure acrylic emulsion which can be mixed with cement, and 3-13 percent of ethylene - polyvinyl acetate emulsion; component B: 3- 20 percent of coarse whiting, 3-13 percent of saponite, 1-13 percent of titanium pigment, 1-6 percent of calcined kaolin, 5-16 percent of hollow sodium silicate particles with the average size approximating to 10 to 70 Mum, and 57-88 percent of the cement, wherein, A:B is equal to 1:0.8-1.3. The invention can be used for roofs and exterior walls, etc. and has the advantages of good heat insulation and waterproof effect, fine durability, easy coating, low cost and water-base environmental protection.

Owner:胡月祖

Water-based self-crosslinking acrylic acid iron oxide red antiseptic paint and preparation method therefor

InactiveCN103642338AReduce contentLow water absorptionAnti-corrosive paintsWater basedPerformance index

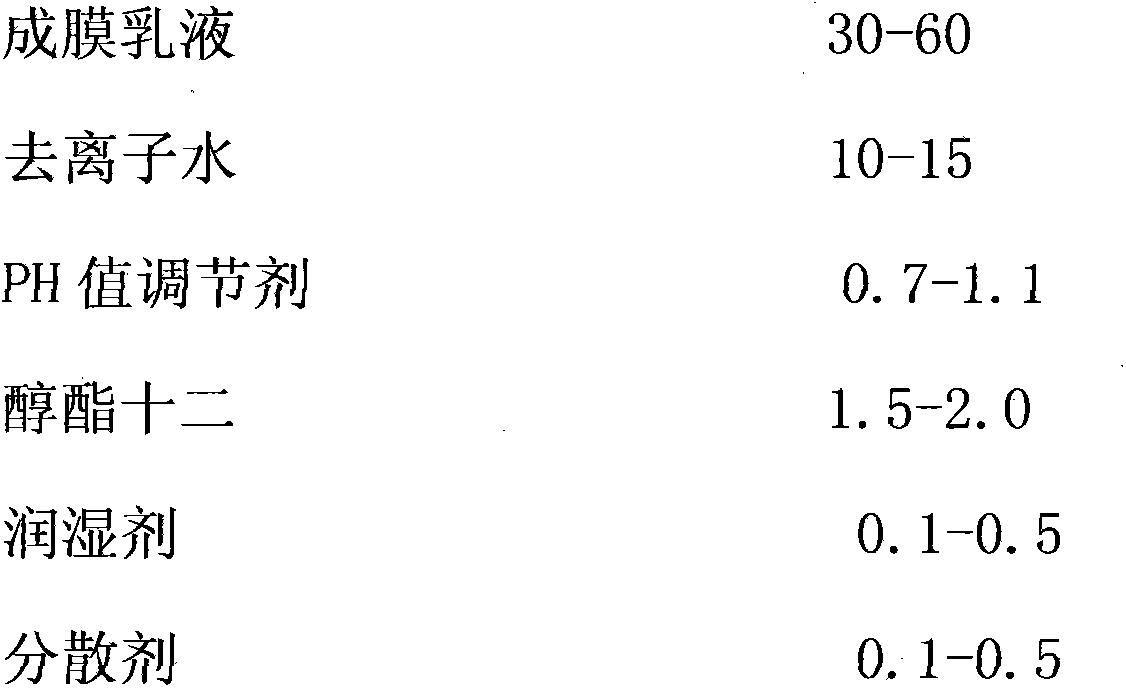

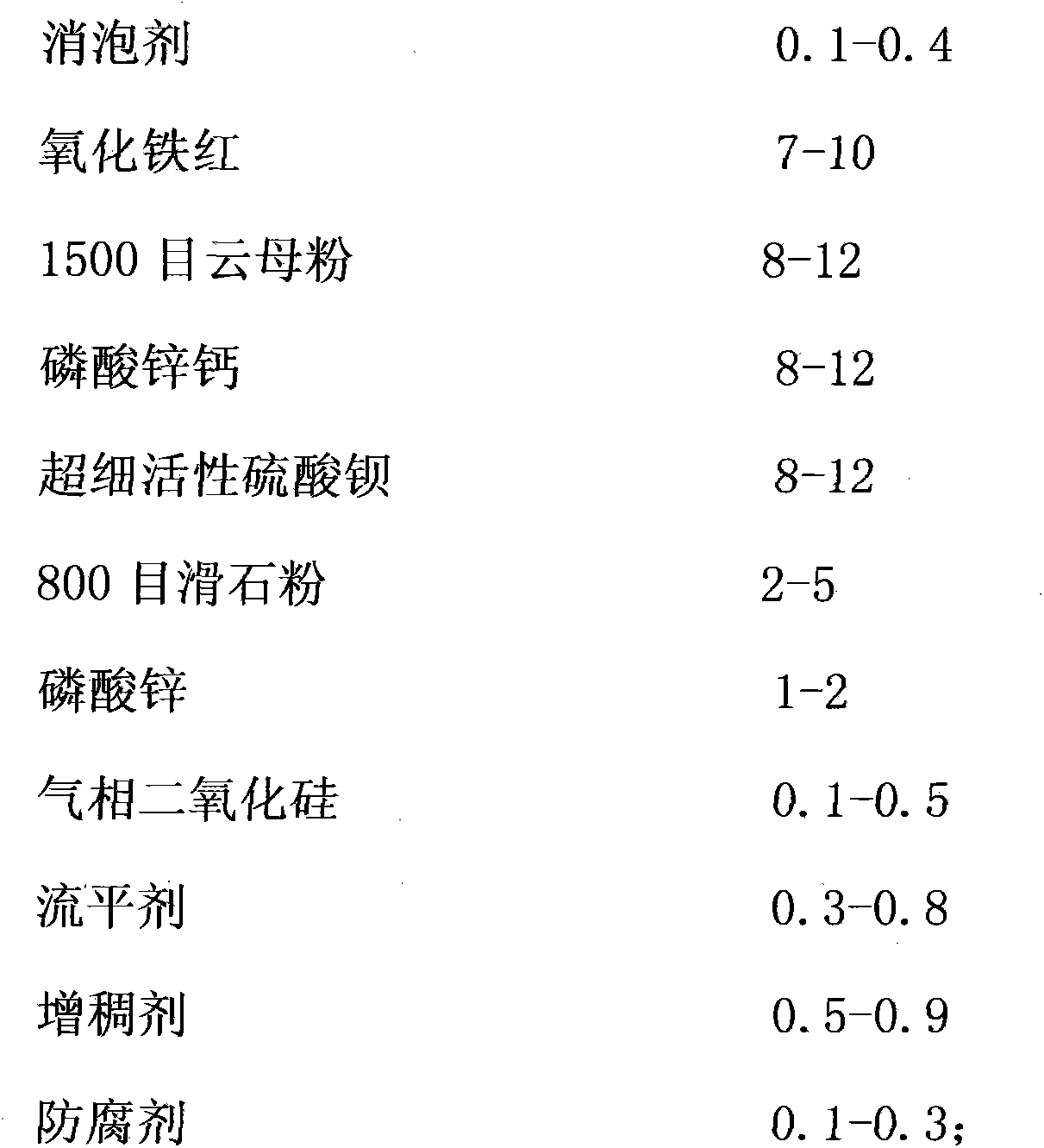

The invention relates to the paint technology field, and especially relates to a water-based self-crosslinking acrylic acid iron oxide red antiseptic paint. The antirust paint comprises the following ingredients, by weight, 30-60 parts of film forming emulsion, 10-15 parts of deionized water, 0.7-1.1 parts of pH value adjusting agents, 1.5-2.0 parts of texanol ester alcohol, 0.1-0.5 part of wetting agents, 0.1-0.5 part of dispersing agents, 0.1-0.4 part of antifoaming agents, 7-10 parts of iron oxide red, 8-12 parts of mica powder, 8-12 parts of zinc calcium phosphate, 8-12 parts of superfine active barium sulfate, 2-5 parts of talcum powder, 1-2 parts of zinc phosphate, 0.1-0.5 part of fumed silica, 0.3-0.8 part of flatting agents, 0.5-0.9 part of thickening agents and 0.1-0.3 part of aseptics. In the method, deionized water replaces traditional organic solvents, various performance indexes all reach standards, no abnormal phenomena are generated, the antiseptic paint is air free and odourless, improves environmental factors greatly, raises safety factors and has very obvious effects.

Owner:抚顺市海丰化工有限公司

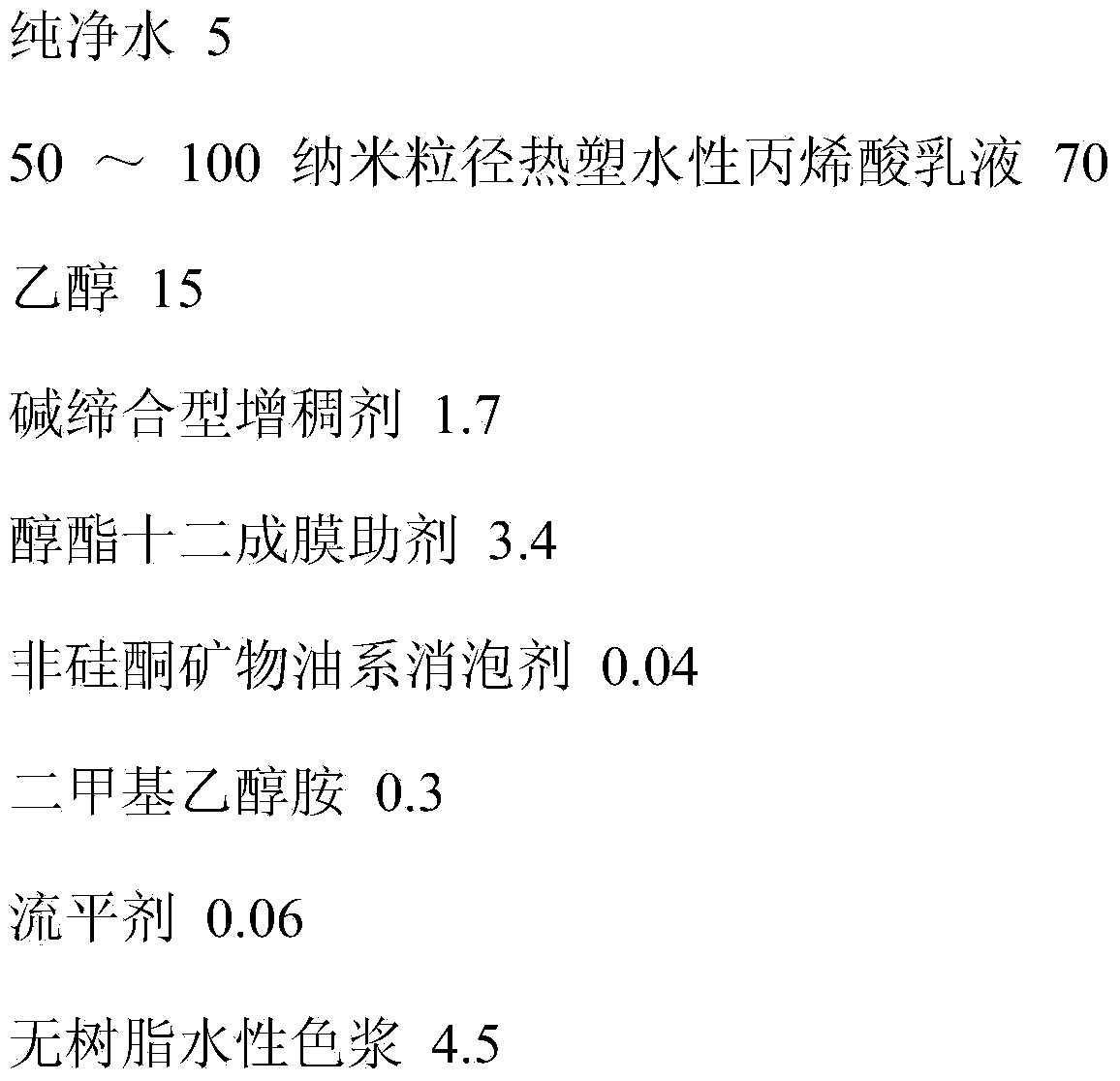

Aqueous plastic paint and construction method thereof

InactiveCN102533027ANon-flammableSpeed up evaporationPretreated surfacesCoatingsAdjuvantAssociation type

The invention discloses an aqueous plastic paint which comprises the following components by weight percent: 5% of purified water, 70% of (50-100 nano particle size) thermoplastic aqueous acrylic emulsion, 15% of ethanol, 1.7% of alkaline association type thickening agent, 3.4% of dodecyl ester film-forming adjuvant, 0.04% of non-silicone mineral oil defoaming agent, 0.3% of dimethylethanolamine, 0.06% of flatting agent and 4.5% of non-resin aqueous color paste. According to the invention, a nano thermoplastic aqueous acrylic acid resin is adopted, thus a paint film is good in adhesive power; and main raw materials in the formula belong to an aqueous system, and no toxic organic solvent is contained in the formula. Simultaneously, through using a construction method disclosed by the invention, the rapid film formation at room temperature is achieved in normal temperature environment; and in the common coating environment, the aqueous plastic paint has small possibility of adsorbing environment dust to generate particles.

Owner:WENZHOU BANGXUAN TECH

Epoxy modified acrylic resin for sealant and preparing method thereof

InactiveCN105524231AImprove heat resistanceGood anti-stickinessGraft polymer adhesivesSolventButyl acrylate

The invention discloses epoxy modified acrylic resin for a sealant and a preparing method thereof; the epoxy modified acrylic resin is prepared from the following raw materials in parts by weight: 50-60 parts of methyl methacrylate, 40-50 parts of butyl acrylate, 2-5 parts of acrylic acid, 1.5-2.0 parts of an initiator, 8-12 parts of epoxy resin, 60-80 parts of a solvent, and 2-4 parts of dodecyl mercaptan. The epoxy modified acrylic resin for the sealant integrates the advantages of epoxy resin and acrylic resin, so that a composite emulsion has the advantages of excellent heat resistance, back sticking resistance, mechanical properties, excellent adhesion power and the like; and the preparation process is simple, and industrialized production can be achieved.

Owner:GUILIN HEXIN WATERPROOF DECORATION MATERIAL

Production technology of core-shell type room-temperature self-crosslinking acrylate emulsion

The invention discloses a production technology of a core-shell type room-temperature self-crosslinking acrylate emulsion. A room-temperature self-crosslinking monomer is introduced by adopting a seed pre-emulsification semi-continuous core-shell emulsion polymerization process; and the acrylate emulsion which has a hard-core and soft-shell structure, is self-crosslinked at room temperature and can be applied to a wood coating is synthesized. The emulsion with a core-shell structure has the advantages of good after-tack resistance, low film-forming temperature, relatively good film-forming property, stability and mechanical property; hard monomers SM and MMA have relatively high glass transition temperature; a film has relatively high hardness, glossiness, weather fastness, anti-fouling performance, cohesion and structure strength; soft monomers BA and 2EHA play an internal plasticization role in a polymerization system; and the film has certain flexibility and adhesiveness.

Owner:QINGDAO SHOUSHENG IND

Anti-back-sticking water-based acrylic emulsion and preparing method and application thereof

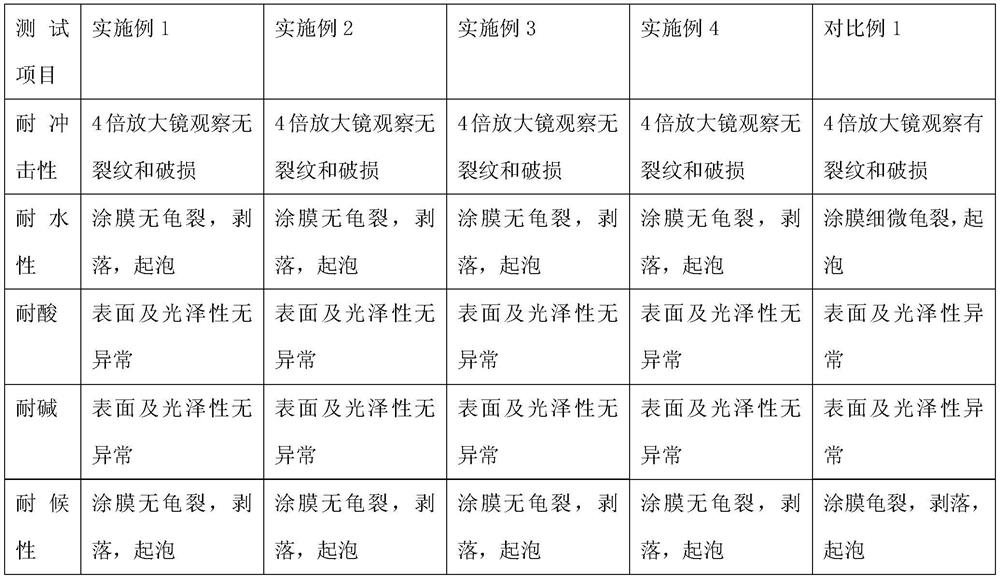

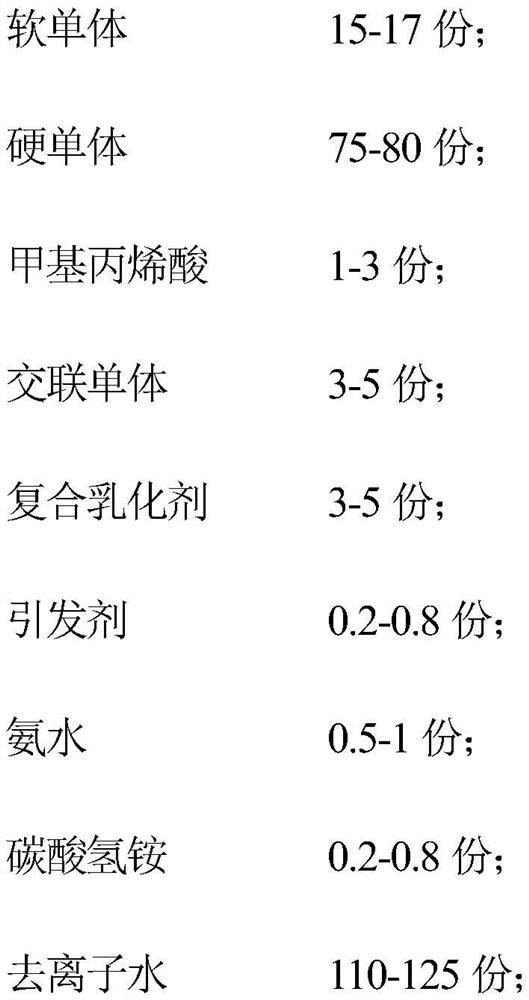

The invention discloses an anti-back-sticking water-based acrylic emulsion and a preparing method and application thereof. The anti-back-sticking water-based acrylic emulsion in the formula is prepared from, by weight, 15-17 parts of a soft monomer, 75-80 parts of a hard monomer, 1-3 parts of methacrylic acid, 3-5 parts of a crosslinking monomer, 3-5 parts of a compound emulsifier, 0.2-0.8 part ofan initiating agent, 0.5-1 part of ammonia water, 0.2-0.8 part of ammonium bicarbonate and 110-125 parts of deionized water. The preparing raw materials of the anti-back-sticking water-based acrylicemulsion are easy to obtain, the price is low, and the anti-back-sticking water-based acrylic emulsion is suitable for industrial production; the preparing method is simple, the temperature is easy tocontrol, and the particle diameter of the obtained emulsion is even; A PVC board is coated with the anti-back-sticking water-based acrylic emulsion, and has the excellent anti-back-sticking performance and adhesive force, water resistance and freeze-thaw stability.

Owner:NANJING REGAL POLYMER

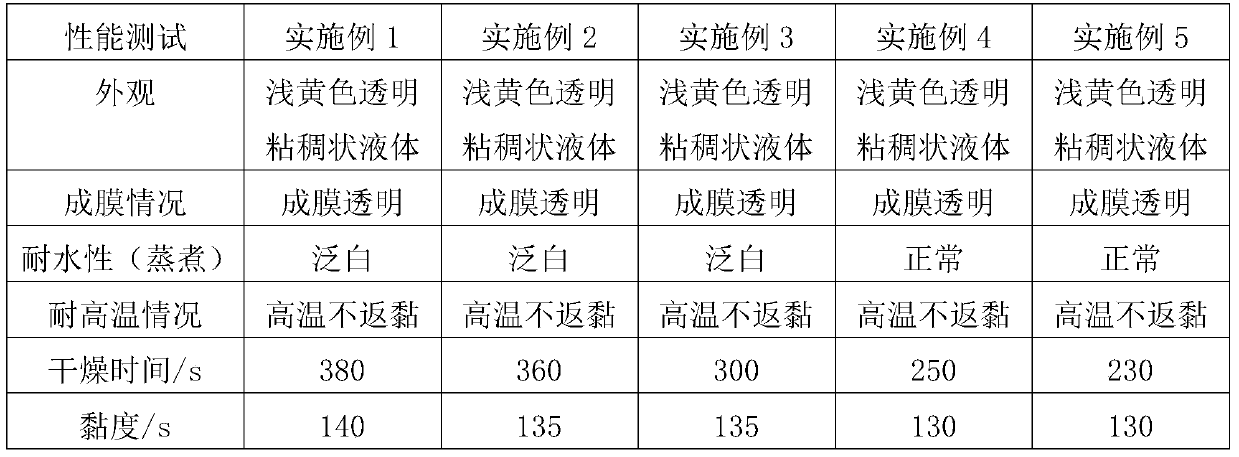

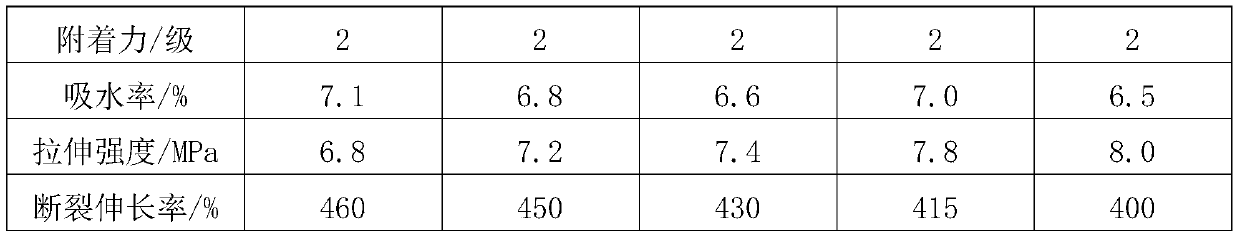

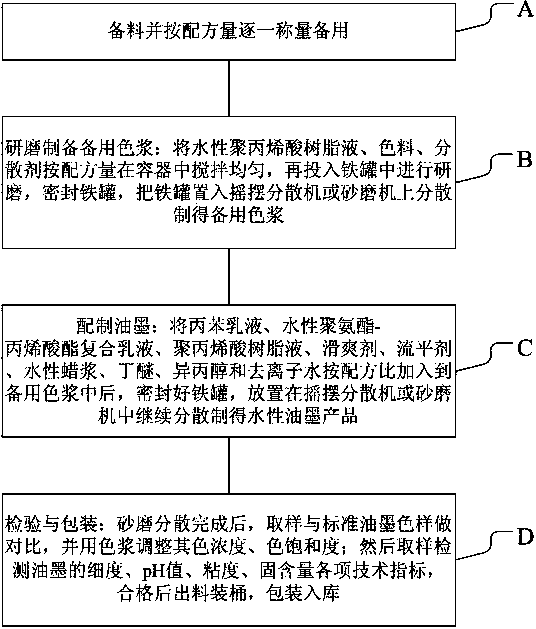

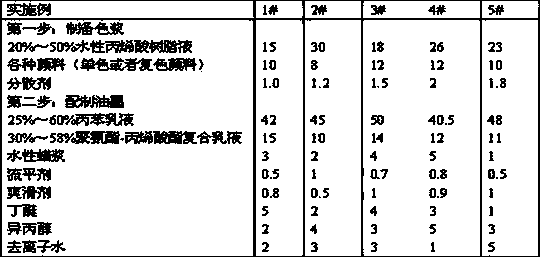

Hydrophilic ink for intaglio printing on surfaces of aluminum foils and preparation method thereof

The invention discloses hydrophilic ink for intaglio printing on surfaces of aluminum foils and a preparation method thereof. The hydrophilic ink for intaglio printing on the surfaces of the aluminum foils comprises the following raw materials: by weight, 15 to 30 parts of hydrophilic polyacrylic resin liquid containing 20% to 50% solid materials (solid content for short), 40 to 50 parts of propyl benzene emulsion with solid content 25% to 60%, 10 to 15 parts of hydrophilic polyurethane and acrylate ester composited emulsion with solid content 30% to 58%, 8 to 12 parts of colorant, 1 to 2 parts of dispersant, 0.5 to 1 part of slip agent, 0.5 to 1 part of flatting agent, 1 to 5 parts of hydrophilic wax syrup, 1 to 5 parts of butyl ether, 1 to 5 parts of isopropanol and 1 to 5 parts of deionized water. The hydrophilic ink is faster in drying speed, fine in adhesion, better in water resistance, moisture resistance and friction resistance, and better in after-tack property. Besides, the hydrophilic ink has fine film formation and color retention and better color development for pigments and also has high glossiness.

Owner:佛山市顺德区乐从镇盛昌油墨有限公司 +1

Anti-pollution pearlescent exterior wall paint

InactiveCN101302386AScrub resistanceWeather resistantAntifouling/underwater paintsPaints with biocidesWater basedSoft water

The invention discloses an antifouling pearlescent outer wall paint. The antifouling pearlescent outer wall paint is characterized by mainly consisting of the following materials in percentage by weight: 3 to 28 percent of soft water, 0.1 to 0.23 percent of hydroxyethylcellulose, 0.1 to 0.2 percent of preservative, 0.1 to 0.4 percent of mildewcide, 1 to 3 percent of propanediol, 0.1 to 0.28 percent of organic amine, 0.1 to 0.3 percent of amine salt dispersant, 0.01 to 0.1 percent of low-foam wetting agent, 0.03 to 0.23 percent of defoaming agent, 60 to 90 percent of silicon modified pure acrylic emulsion with a vitrification temperature of over 33 DEG C, 1 to 3 percent of ethylene-polyvinyl acetate emulsion, 3 to 5 percent of dodecanol lipid, 5 to 20 percent of pearlescent powder with good weather resistance and 0.1 to 0.3 percent of thickening agent. The paint is used for an outdoor craftwork, an outer door, etc, has high hardness and good flexility, weather resistance, scrub resistance and antifouling property, also emits fascinated luster like jewelry and is water-based environment-friendly.

Owner:胡月祖

Aqueous toy paint and method for making same

The invention discloses water-base toy paint and a production process, which is prepared by dispersion resin, propanediol ether, 20% ammonia, deionized water, ruite titanium dioxide, ultra-fine talc, 15-25 ultra-fine calcium carbonate and defoaming agent. The production process comprises adding dispersion resin, propanediol ether, ammonia, deionized water into a material-preparing pot, evenly agitating and mixing in low speed, then adding defoaming agent to evenly mix, adding pigment and filler to form even paint paste through dispersing in high speed, throwing paint paste into a regulating tank after grinding, agitating to mix evenly in low speed, adding deionized water to dilute. The paint of the invention has environmental-friendly water-base, fast coalescence to blocks, excellent sealing and anti-bonding property, can effectively make up the partial weaknesses and shortcomings of substrate material, prevents the generation of wood grease and spurs, has strong adhesion, high painting film, favorable binding resistance, excellent flat surface of paint film, water resistance and stability, and has excellent toughness, no tending to get soft and corrosion resistance and suitable price.

Owner:刘善江

Black water-based full-shading electromagnetic wave shielding coating and preparation method thereof

InactiveCN114369380AImprove toughnessGood anti-stickinessPolyurea/polyurethane coatingsNew energyElectromagnetic radiation

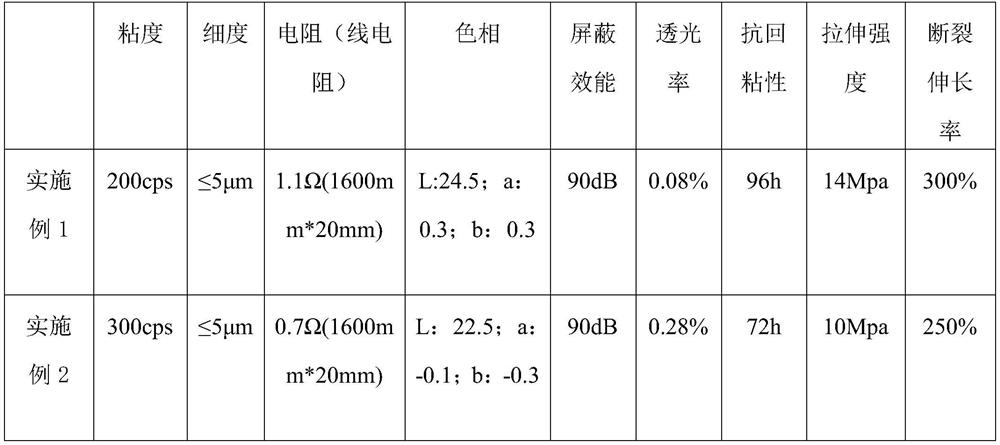

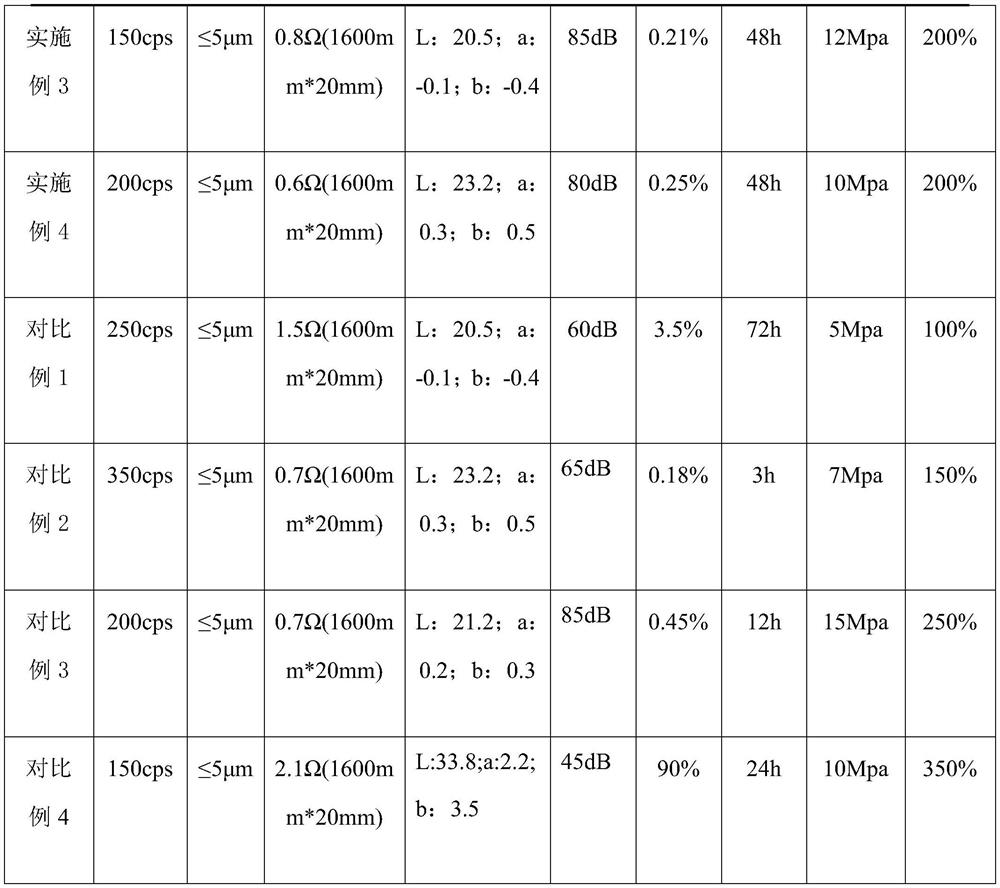

The invention discloses a black water-based full-shading electromagnetic wave shielding coating which is coated on a conductive substrate and comprises the following components in percentage by mass: 1-20% of polyurethane-acrylic copolymer, 1-20% of acrylic emulsion, 15-35% of nano black paste, 5-10% of polytetrafluoroethylene wax dispersion, 1-1.5% of wetting dispersant, 0.1-1% of flatting agent, 5-10% of coalescing agent, 0.5-1% of thickening agent and the balance of water. The coating has the advantages of being low in light transmittance, good in after-tack resistance, high in electromagnetic wave shielding performance and the like, is applied to various electromagnetic compatibility environments, such as the fields of communication, IT, electric power, medical treatment, electronics, military industry, new energy automobiles and the like, and prevents electromagnetic information leakage and electromagnetic radiation pollution; normal work of instruments and equipment is effectively guaranteed, safety of confidential information is guaranteed, body health of workers is guaranteed, and the problems that in the prior art, paint is high in light transmittance and poor in shielding effectiveness are solved.

Owner:GUANGZHOU QIANSHUN IND MATERIAL

Weatherproof inorganic exterior wall coating based on graphene and mullite and preparation method thereof

ActiveCN109206948ADoes not fall offWaterproofFireproof paintsAntifouling/underwater paintsMulliteFire prevention

The invention relates to a weatherproof inorganic exterior wall coating based on graphene and mullite and a preparation method thereof, and belongs to the field of graphene-based wall inorganic coatings. The weatherproof inorganic exterior wall coating includes the following components by the mass percentage: 5-15% of mullite, 6-15% of perlite, 1-20% of graphene, 2-10% of vitrified micro-beads, 3-10% of sepiolite, 6-15% of albite, 5-18% of light calcium carbonate, 5-10% of bauxite, 2-8% of nano titanium dioxide, 10-15% of nano-silica sol, 20-30% of an auxiliary agent, and 3-6% of a pure acrylic emulsion. The coating has the advantages of strong bonding strength, simple construction and scouring resistance. At the same time, under high temperature conditions, a coating layer is not blistered and cracked or does not fall off, and plays the effects of water prevention, fire prevention, salt resistance, alkali resistance, heat insulation, heat preservation, corrosion prevention, rust prevention and aging resistance.

Owner:GUANGXI XUTENG INDUSTRIAL GROUP CO LTD

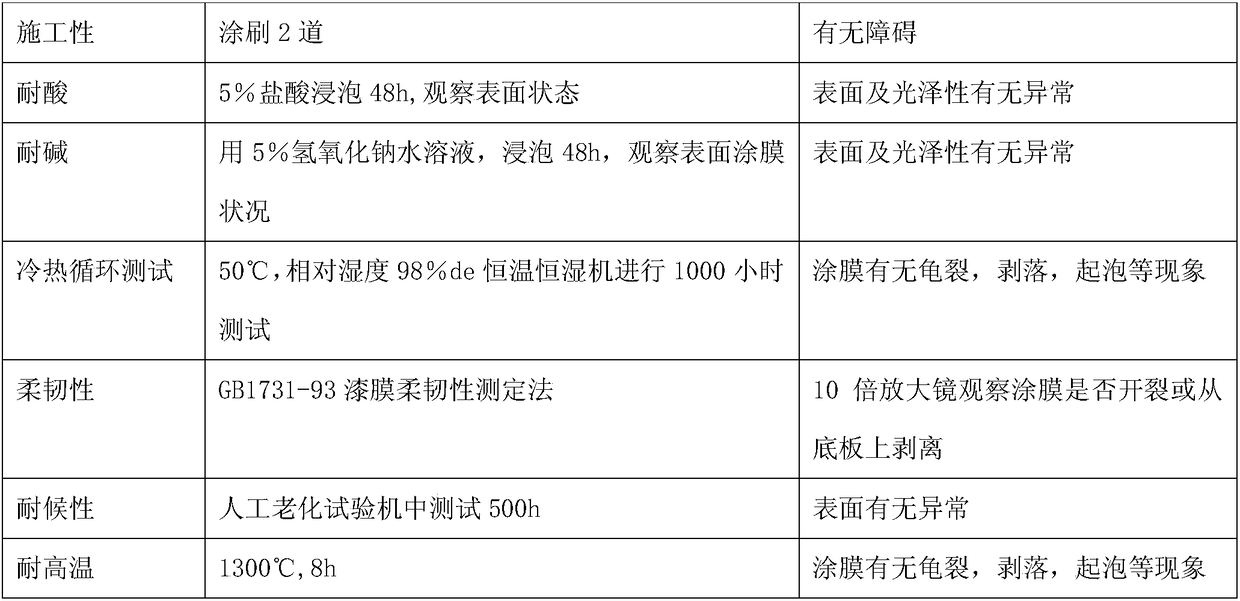

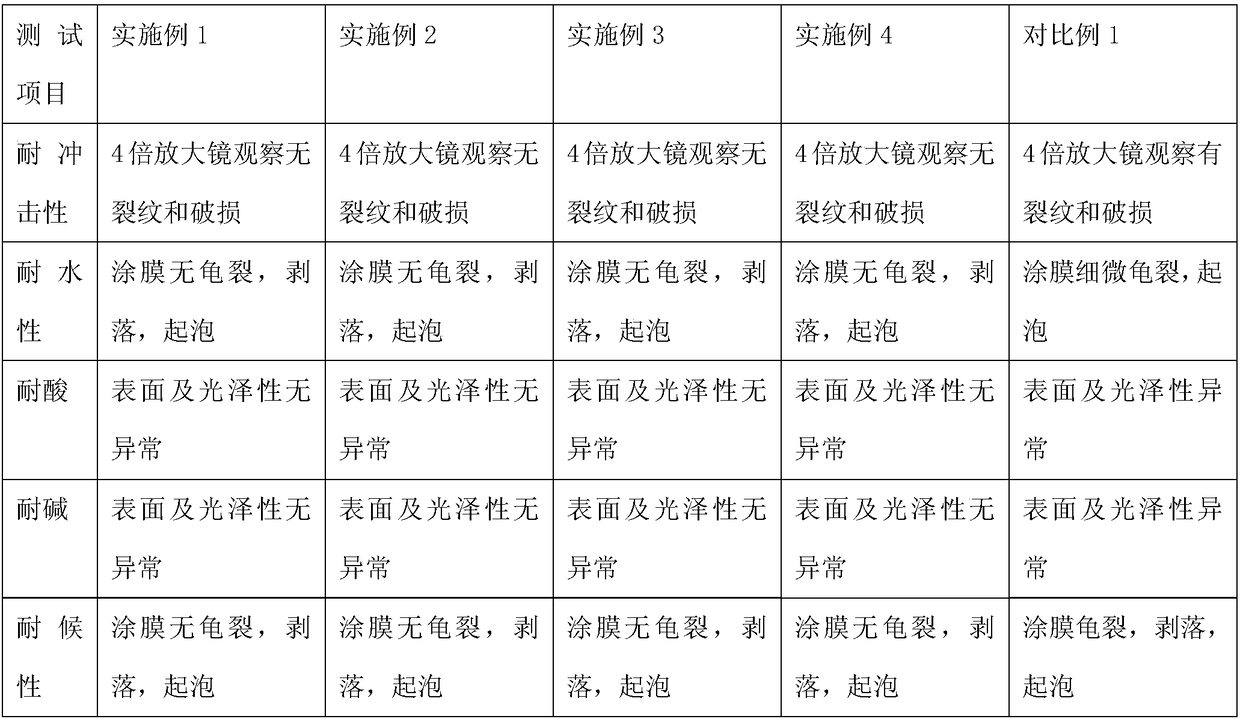

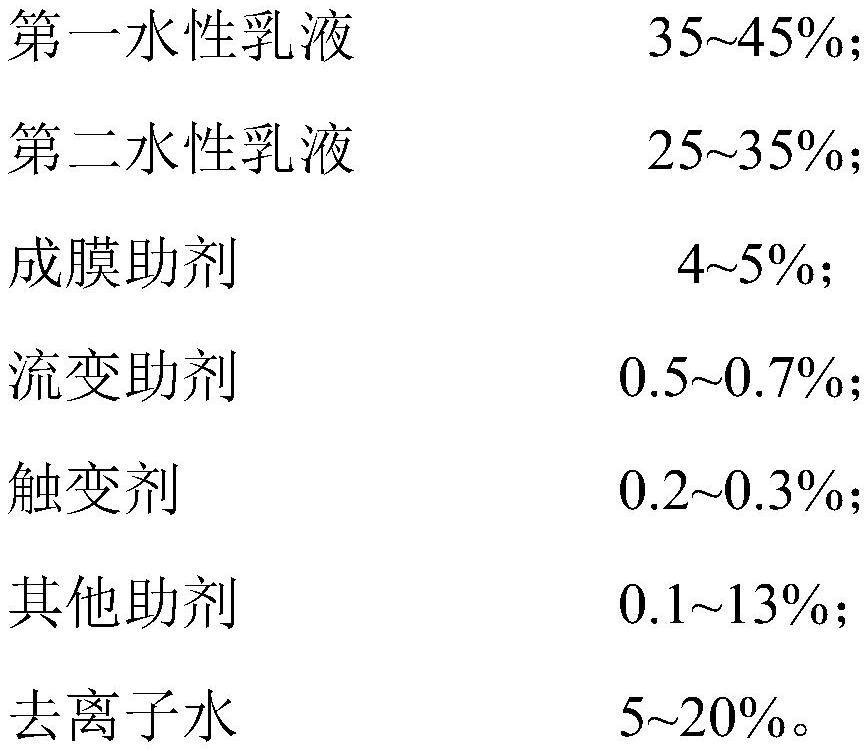

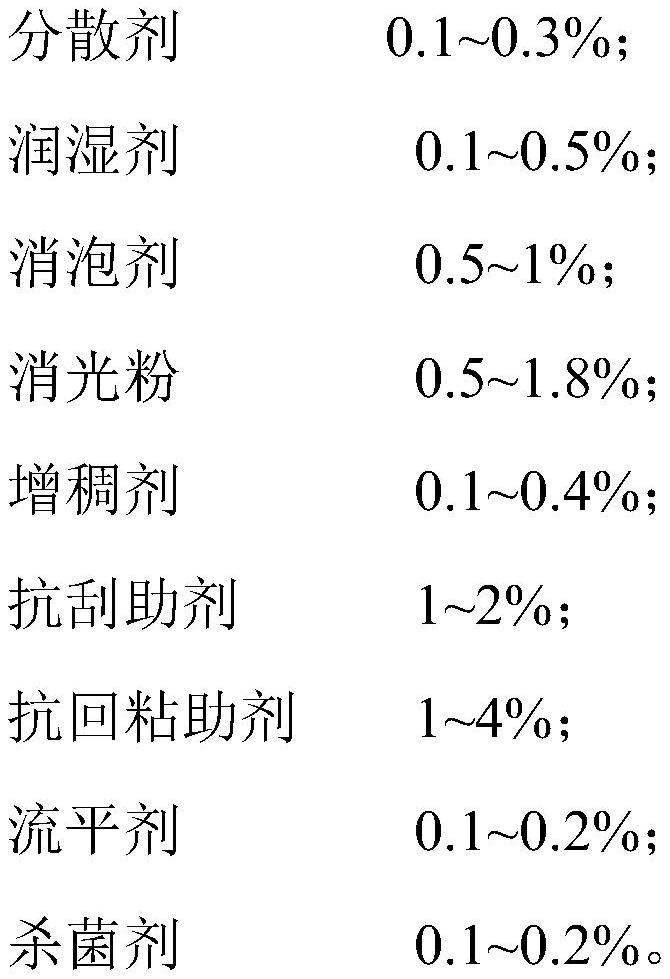

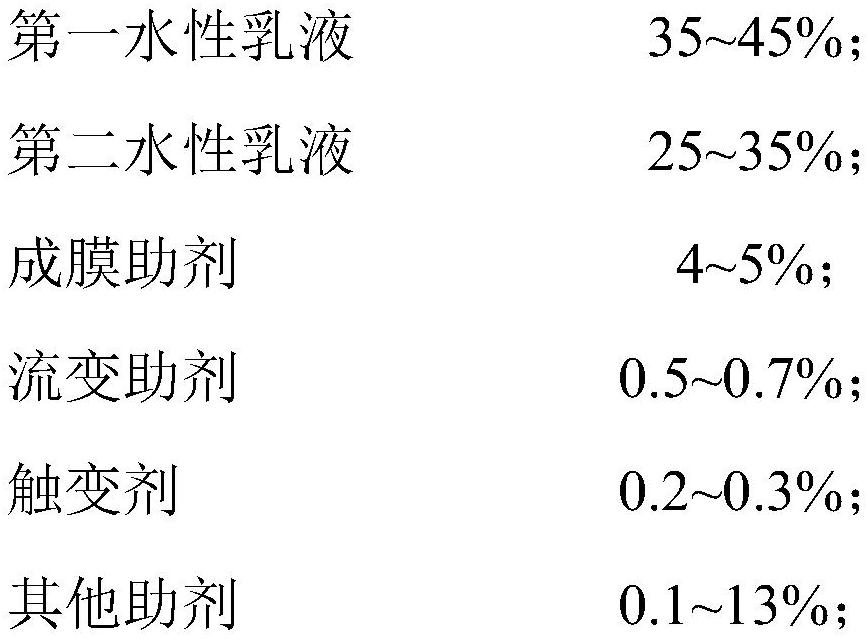

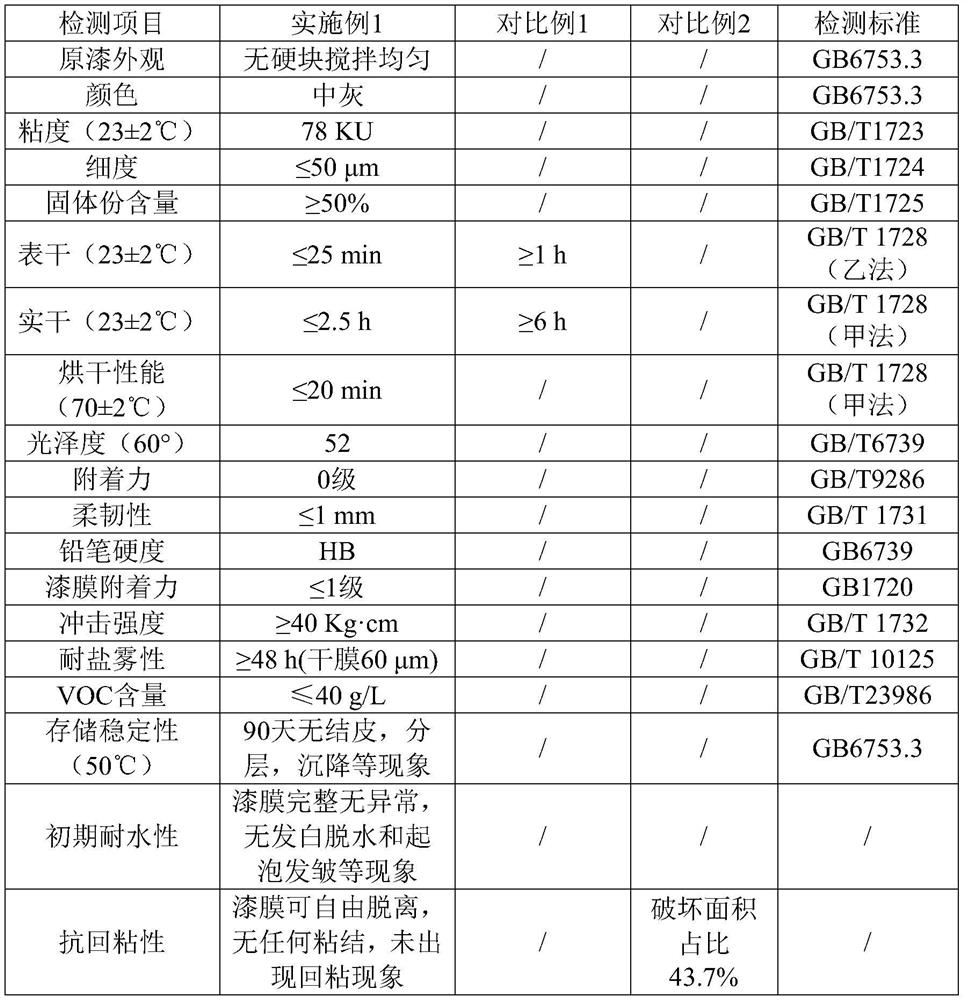

Water-based electrostatic finishing paint and preparation method thereof

The invention relates to the technical field of water-based wood paints, and provides a water-based electrostatic finishing paint, which comprises the following components in percentage by weight: 35-45 percent of first water-based emulsion, 25-35 percent of second water-based emulsion, 4-5 percent of coalescing agent, 0.5-0.7 percent of rheological agent, 0.2-0.3 percent of thixotropic agent, 0.1-13 percent of other auxiliaries and 5-20 percent of deionized water based on 100 percent of total weight of the water-based electrostatic finishing paint. The obtained water-based electrostatic finishing paint is suitable for electrostatic spraying, does not have a sagging phenomenon, has the characteristics of high drying speed, good after-tack resistance and good stacking resistance, can be effectively used for electrostatic spraying, is uniform in coating and relatively good in painting effect in the use process, improves the production efficiency and reduces the production cost.

Owner:中华制漆(新丰)有限公司

Bamboo-carbon coating hardly containing organic solvent

InactiveCN101302382AHas the function of purifying the environmentReduce contentEmulsion paintsCarbon coatingWater based

The invention discloses a bamboo carbon paint which almost contains no organic solvent. The bamboo carbon paint is characterized in that the paint mainly consists of the following materials in percentage by weight: 20 to 40 percent of soft water, 0.1 to 0.3 percent of hydroxyethylcellulose, 0.1 to 0.2 percent of preservative, 0.1 to 0.3 percent of mildewcide, 0.2 to 0.5 percent of dispersant, 0.02 to 0.1 percent of low-foam wetting agent, 0.1 to 0.3 percent of defoaming agent, 1 to 6 percent of silicone-acrylic emulsion with a lowest film forming temperature of 10 DEG C below zero, 8 to 13 percent of ethylene-polyvinyl acetate emulsion, 40 to 60 percent of bamboo carbon powder with an average grain diameter of between 10 and 38mu m around and 0.1 to 0.6 percent of thickening agent. The paint is used for craftwork, an inner wall, etc, has the function of environment purification, almost contains no organic solvent and is water-based environment-friendly.

Owner:胡月祖

Water-based after-tack-resistant anticorrosive primer as well as preparation method and application thereof

InactiveCN112143309AGood anti-stickinessFast dryingAnti-corrosive paintsEpoxy resin coatingsEpoxyPolymer science

The invention discloses a water-based after-tack-resistant anticorrosive primer and a preparation method and application thereof.The water-based after-tack-resistant anticorrosive primer is prepared from water-based epoxy ester resin, acrylic emulsion and auxiliaries, the mass ratio of the water-based epoxy ester resin to the acrylic emulsion is 6-10: 15-25, the solid content of the acrylic emulsion is 45%-50%, and the particle diameter is 0.1-0.2 <mu>n; and the lowest film forming temperature is 20-25 DEG C. The water-based after-tack-resistant anticorrosive primer disclosed by the inventionhas excellent after-tack-resistant performance and is high in drying speed.

Owner:GUANGZHOU JOINTAS CHEM +1

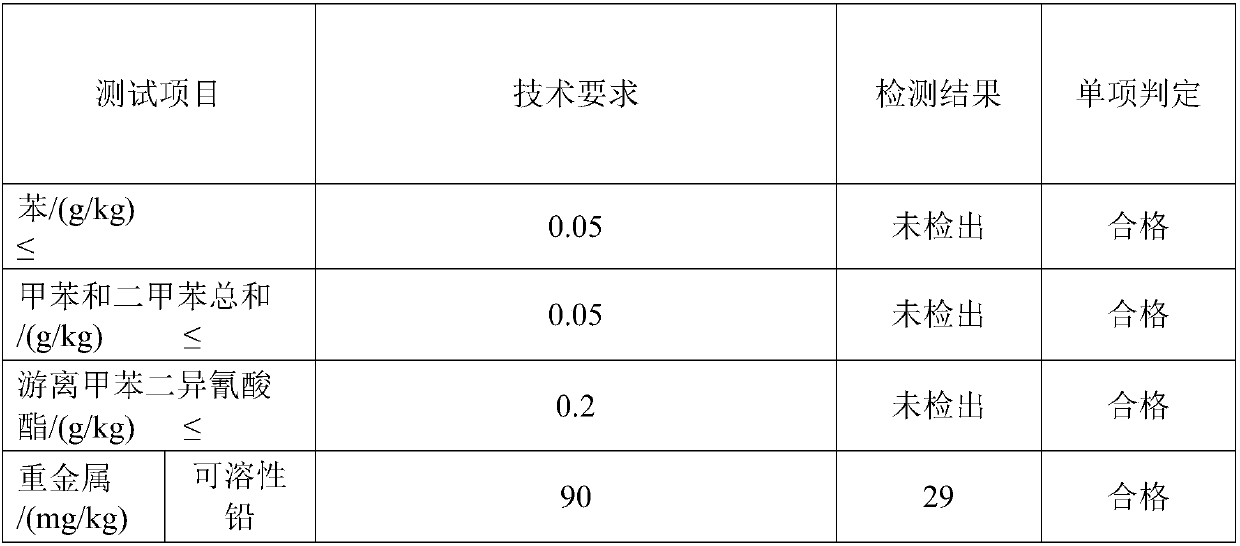

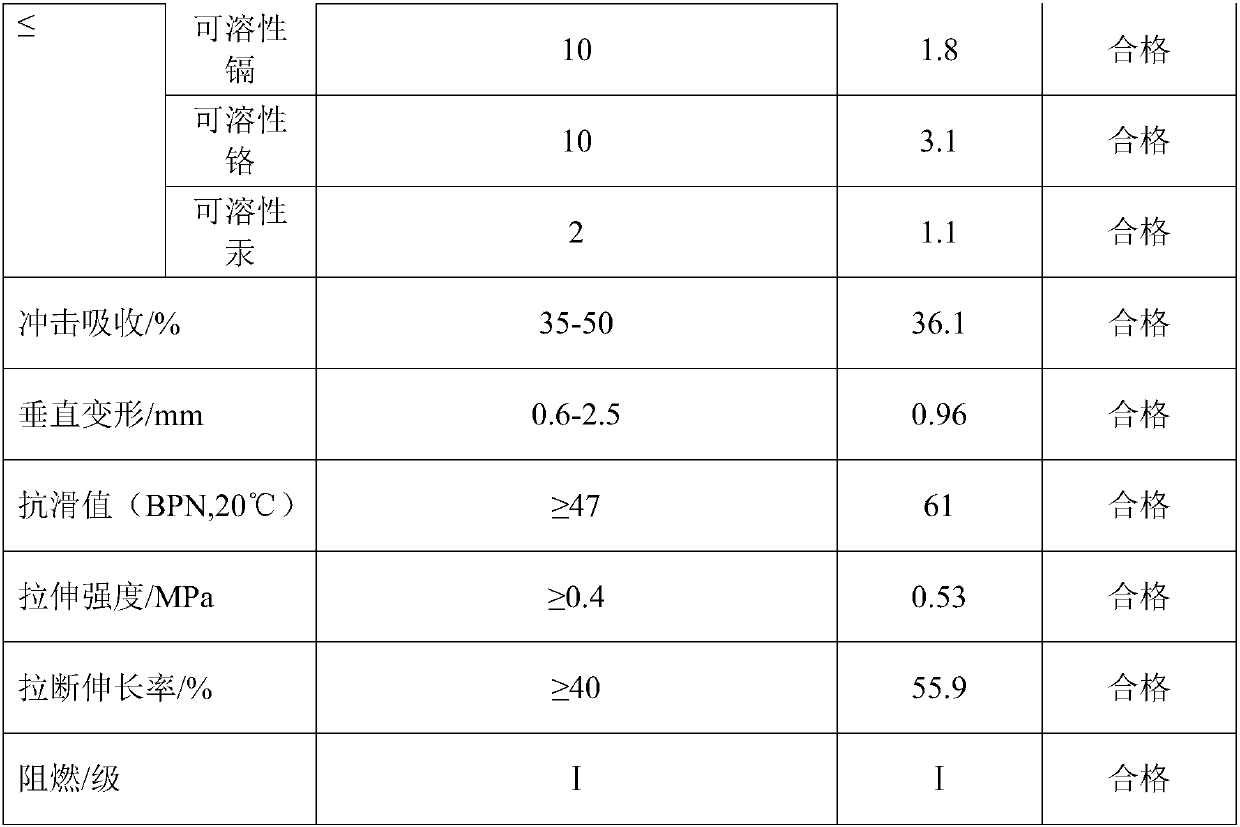

A high-performance water-based environmentally friendly plastic runway

InactiveCN105803896BSolve environmental problemsHigh strengthGround pavingsCoatingsEnvironmental resistanceWater based

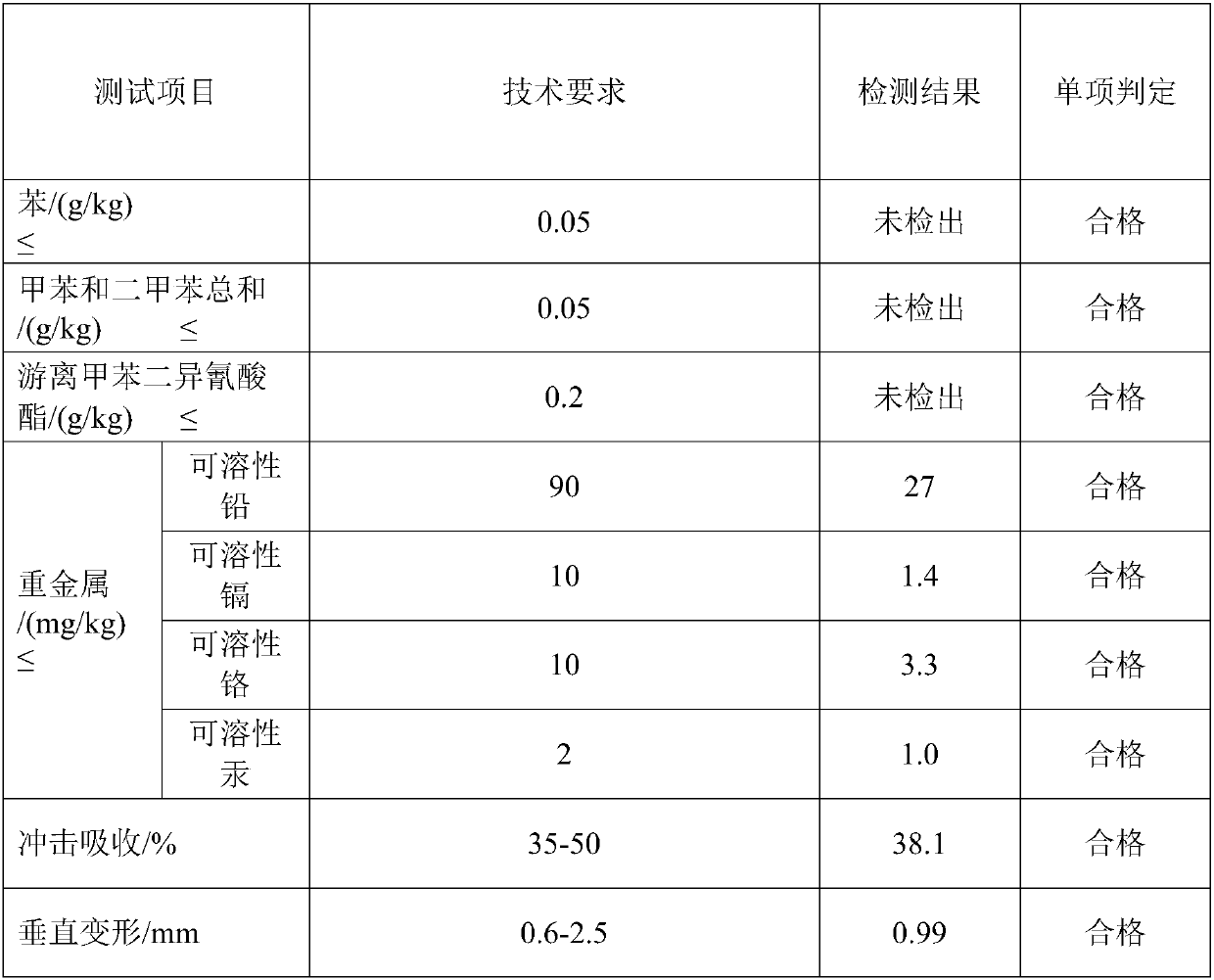

The invention relates to a high-performance and environment-friendly waterborne plastic track. The high-performance and environment-friendly waterborne plastic track sequentially comprises an environment-friendly waterborne plastic layer, an asphalt concrete layer, a cement and rock flour stabilizing layer, graded broken stone and lime soil from top to bottom, wherein the environment-friendly waterborne plastic layer comprises a waterborne plastic track surface layer, a waterborne plastic track buffer layer and a waterborne plastic track bottom layer arranged from top to bottom sequentially. Compared with the prior art, the high-performance and environment-friendly waterborne plastic track doesn't contain any free TDI, doesn't contain harmful additives and solvents and is non-toxic and odorless; meanwhile, during use, no harmful substances with peculiar smell are discharged, and the high-performance and environment-friendly waterborne plastic track has a good mechanical property and meets the national standard requirements.

Owner:上海北新月皇新材料集团有限公司

Soap-free polymerized acrylic acid emulsion and preparation method thereof

The invention discloses a soap-free polymerized acrylic acid emulsion and a preparation method thereof. Its raw materials contain 15-22% of methyl methacrylate, 16-21% of isooctyl acrylate, 0.6-1% of methacrylic acid, and 7-2% of styrene. 10%, acrylamide is 0.3-0.6% monomer, ammonium persulfate or potassium persulfate is 0.1-0.4% initiator, alkylamide vinyl sulfonate or sodium dodecylbenzene sulfonate is 0.4-1.2% Emulsifier, ammonia water is 0.2-0.4% of pH regulator, and water is 45-55%. Soap-free polymerized acrylic emulsion was prepared by pre-emulsification, seed polymerization and polymerization. The invention not only maintains the advantages of the traditional emulsion, but also has excellent water whitening resistance and excellent water resistance of the paint film. Excellent weather resistance, no yellowing. Fine particle size and high gloss, good color development. Excellent dry and wet adhesion; excellent resistance to weathering and salting-out. The paint film is tough and dense, with good hardness, excellent stain resistance and anti-adhesion. It lowers the product cost and has wide applicability, and is used to prepare high-performance flat to high-gloss coatings for external use.

Owner:山东聚东新材料有限责任公司

Coating process of water-based plastic substitute

PendingCN113185910AGood flexibilityImprove hydrolysis resistancePretreated surfacesPolyurea/polyurethane coatingsIsocyanatePolyester

The invention relates to the technical field of paper plastic processing, in particular to a coating process of water-based plastic substitute. The invention is improved from polyol, and polyester polyol is selected between polyether polyol and polyester polyol. Although polyurethane synthesized by polyether polyol has better flexibility and hydrolysis resistance, polyurethane synthesized by polyester polyol has stronger cohesive energy and more excellent after-tack resistance, in addition, excessive isocyanate with a cyclic monomer is adopted to react with polyester polyol, so that the tensile strength of the polyurethane is improved, and the tensile strength of the polyurethane is improved. The further initiation of the cyclic monomer can improve the strength and water resistance of the coating, then the cyclic monomer reacts with hydroxyethyl acrylate and a hydrophilic chain extender to form a polyurethane acrylate aqueous system, the system has good emulsion stability, and an adhesive film with good hardness, flexibility, adhesiveness, after-tack resistance and water resistance can be rapidly formed through photocuring.

Owner:东莞市冠力胶业有限公司

Stone-like coating added with ginger nut sand

InactiveCN112341882AImprove waterproof performanceGood weather resistanceAntifouling/underwater paintsPaints with biocidesCellulosePolymer science

The invention discloses stone-like coating added with ginger nut sand. The stone-like coating is prepared from the following raw materials in parts by weight: 200-300 parts of pure acrylic emulsion-pure acrylic copolymer emulsion; 56-100 parts of an elastic emulsion; 3-7 parts of a coalescing agent; 3-7 parts of ethylene glycol monobutyl ether; 20-60 parts of steel slag powder; 550-780 parts of ginger nut sand; 30-60 parts of nano tourmaline powder; 5-10 parts of a carbomer dispersion liquid; 4-10 parts of lithospermum oil; 2-5 parts of a defoaming agent; 70-120 parts of 2% hydroxyethyl cellulose; 3-7 parts of a thickening agent; proper amount of purified water. The stone-like coating is attractive, environment-friendly and excellent in waterproof performance, and can effectively protect abuilding from being eroded by a severe environment, so that the service life of the building is prolonged; the stone-like coating not only has good weather resistance and is suitable for various regions, but also is simple and convenient to construct, time-saving and easy to dry, the flexibility of the coating is enhanced, and the stone-like coating has good stain resistance and antibacterial activity.

Owner:王立

Weather-resistant inorganic exterior wall paint based on graphene and mullite and preparation method thereof

ActiveCN109206948BDoes not fall offWaterproofFireproof paintsAntifouling/underwater paintsMulliteMaterials science

The invention relates to a weather-resistant inorganic exterior wall coating based on graphene and mullite and a preparation method thereof, and belongs to the field of inorganic wall coatings based on graphene. ~15%, graphene 1~20%, vitrified microbeads 2~10%, sepiolite 3~10%, albite 6~15%, light calcium carbonate 5~18%, bauxite 5~ 10%, nano-titanium dioxide 2-8%, nano-silica sol 10-15%, additives 20-30%, pure acrylic emulsion 3-6%. The coating has strong bonding strength, simple construction, and the coating is resistant to washing. At the same time, under high temperature conditions, the coating does not bubble, crack, or fall off, and has the functions of waterproof, fireproof, salt resistance, alkali resistance, heat insulation, anti-corrosion, anti-rust, and anti-aging.

Owner:GUANGXI XUTENG INDUSTRIAL GROUP CO LTD

An antibacterial plastic toy water paint

ActiveCN107011778BAchieve adhesionAchieve antibacterial effectAntifouling/underwater paintsPaints with biocidesPolymer scienceHazardous substance

The invention relates to the technical field of paint, in particular to the technical field of water-based paint, and in particular discloses an antibacterial water-based paint for plastic toys. The antibacterial water-based paint for the plastic toys is prepared by mixing two types of waterborne polyurethane having different hydroxyl values and two types of isocyanate having different NCO contents, and adding an antibacterial agent; the physical and chemical properties of the obtained water-based paint reach the standard of solvent type products; the water-based paint is good in adhesion force, after-tack resistance and water resistance, low in contents of poisonous and harmful substances such as heavy metals, safe and environmentally-friendly, and good in application property.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Bamboo-carbon bone putty hardly containing organic solvent

The invention discloses a bamboo carbon bone pulp which almost contains no organic solvent. The bamboo carbon bone pulp is characterized in that the bone pulp mainly consists of the following materials in percentage by weight: 6 to 20 percent of soft water, 0.08 to 0.2 percent of hydroxyethylcellulose, 0.06 to 0.15 percent of preservative, 0.08 to 0.2 percent of mildewcide, 0.1 to 0.4 percent of dispersant, 0.02 to 0.1 percent of low-foam wetting agent, 0.08 to 0.26 percent of defoaming agent, 1 to 5 percent of silicone-acrylic emulsion with a lowest film forming temperature of 10 DEG C below zero, 6 to 12 percent of ethylene-polyvinyl acetate emulsion, 60 to 80 percent of bamboo carbon particles with an average grain diameter of between 80 and 5000mu m around and 0.1 to 0.5 percent of thickening agent. The bone pulp is used for craftwork, the inner wall, etc., has the function of environment purification, almost contains no organic solvent and is water-based environment-friendly.

Owner:胡月祖

A kind of anti-back viscoelastic acrylic acid aqueous dispersion and preparation method thereof

The invention discloses an anti-after-tack elastic acrylic aqueous dispersion and a preparation method thereof. The anti-after-tack elastic acrylic aqueous dispersion is prepared from a nano-silica hybridized acrylic emulsion with the high softening point and a nano-silica hybridized acrylic emulsion with the low softening point under the action of a siloxane coupling agent through compounding. The prepared anti-after-tack elastic acrylic aqueous dispersion has good flexibility, anti-after-tackiness and hardness.

Owner:湖南中汉高分子材料科技有限公司

A kind of anti-adhesive water-based acrylic emulsion and its preparation method and application

The invention discloses an anti-sticking water-based acrylic emulsion and its preparation method and application. The weight parts of its formula are: 15-17 parts of soft monomer; 75-80 parts of hard monomer; 1-3 parts of methacrylic acid. ; 3-5 parts of cross-linking monomer; 3-5 parts of composite emulsifier; 0.2-0.8 parts of initiator; 0.5-1 part of ammonia; 0.2-0.8 parts of ammonium bicarbonate; 110-125 parts of deionized water. The raw materials for preparing the anti-sticking water-based acrylic emulsion of the present invention are easy to obtain and low in price, and are suitable for industrial production; the preparation method is simple, the temperature is easy to control, and the particle size of the obtained emulsion is uniform; the anti-sticking water-based acrylic emulsion is coated on a PVC board It has excellent anti-sticking properties, excellent adhesion, water resistance and freeze-thaw stability.

Owner:NANJING REGAL POLYMER

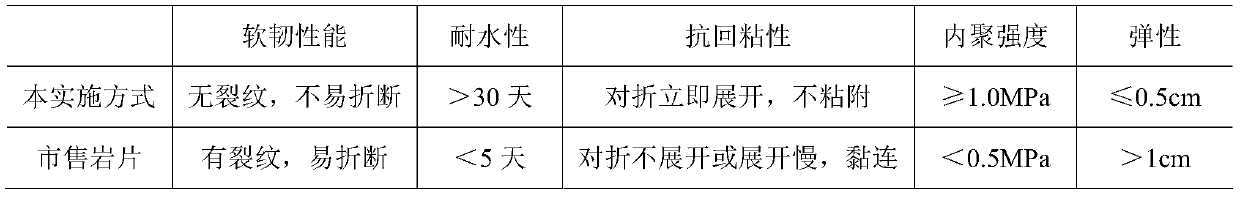

A kind of ultra-soft and ultra-thin composite rock slice and its preparation method

The invention relates to a super-soft super-thin composite rock piece and a preparation method thereof, belonging to the field of new building materials. The super-soft super-thin composite rock piece contains an acrylate emulsion, a defoaming agent, color paste, a dispersing agent, a power raw material, a thickening agent, bentonite, a functional aid A, a functional aid B and the balance of water. The preparation method comprises the steps of sequentially adding the weighed materials into a container while stirring, uniformly stirring at a rotation speed of 300r / min-600r / min for 30-50 minutes so as to obtain a rock piece sizing agent, starting rock piece film forming stirring equipment to prepare a dried film, crushing the dried film in a crusher, and sieving. The super-soft super-thin composite rock piece is extremely low in liquid absorption rate and is soft, good in tenacity and unlikely to break after being put into water; the filminess can be realized, and unfavorable conditions of water resistance difference, fading, color blending, crushing and the like can be avoided; and the rock piece has excellent after-tack resistance and can be cured through a high temperature, a light wave or other manners.

Owner:黑龙江佰嘉生物质材料有限公司

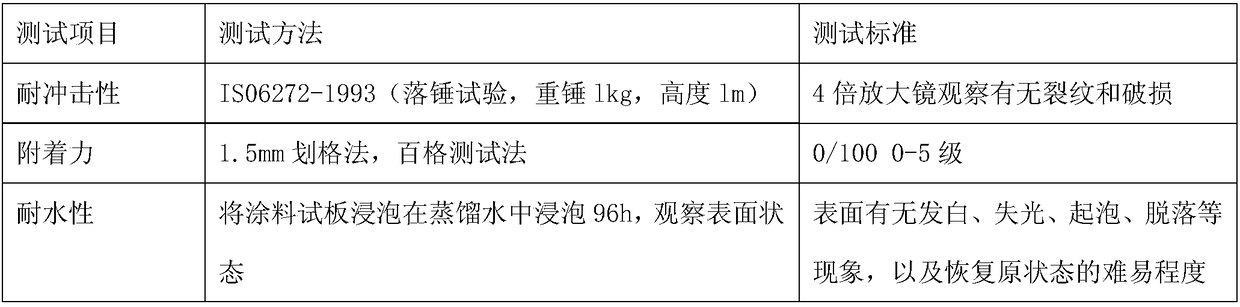

High-gloss washing resistant environmental-friendly print paste and preparation method thereof

The invention discloses high-gloss washing resistant environmental-friendly print paste and a preparation method thereof; the printing paste comprises water-based acrylic emulsion, modified water-based polyurethane emulsion, ammonia, defoaming agent, preservative, water-based wax emulsion, wetting and leveling agent, dispersing agent, toner, moisturizing agent and thickener. The preparation method comprises the steps that: A. stirring and filtration: the water-based acrylic emulsion and the water-based polyurethane emulsion are added into a dispersion cylinder by the formula ratio, and are stirred while being sequentially added with the ammonia, the defoaming agent, the preservative, the water-based wax emulsion, the moisturizing agent, the wetting and leveling agent and the dispersing agent; after the materials are added in, the mixture is stirred for 10min to 20min until being uniform fully; the mixture is filtered by a 200-mesh filter mesh bag; B. dispersion and grinding: the toneris added into the liquid mixture, stirred and dispersed for 30min to 50min; the thickener is added in, stirred and dispersed for 10min to 20min; and then the liquid mixture is ground on a three-roll grinder; and C. detection and packaging: the product is sampled to detect the pH value, the viscosity and the fineness, and the product is packaged after all the indexes are qualified.

Owner:BAILIHE CHEM ZHONGSHAN

Composition for manufacturing gloves and method for manufacturing gloves by using composition

InactiveCN107603100AGood flexibilityGood anti-stickinessLiquid surface applicatorsGlovesAlcoholUltraviolet

The present invention provides a composition used for manufacturing gloves comprising polyacrylate, which has glass transition temperature (Tg) under 20DEG. The composition comprises characteristicsof anti-sticking feature, alcohol resistance, anti-bacteria, anti-mildew, anti-UV, and without allergen. The gloves made by the composition can replace those made by traditional materials such as NBR,PVC, and so on. The composition used for gloves is able to apply to medical and electronics industries.

Owner:CHEM FIRST TAIWAN CO LTD

Aqueous plastic paint and construction method thereof

The invention discloses an aqueous plastic paint which comprises the following components by weight percent: 5% of purified water, 70% of (50-100 nano particle size) thermoplastic aqueous acrylic emulsion, 15% of ethanol, 1.7% of alkaline association type thickening agent, 3.4% of dodecyl ester film-forming adjuvant, 0.04% of non-silicone mineral oil defoaming agent, 0.3% of dimethylethanolamine, 0.06% of flatting agent and 4.5% of non-resin aqueous color paste. According to the invention, a nano thermoplastic aqueous acrylic acid resin is adopted, thus a paint film is good in adhesive power; and main raw materials in the formula belong to an aqueous system, and no toxic organic solvent is contained in the formula. Simultaneously, through using a construction method disclosed by the invention, the rapid film formation at room temperature is achieved in normal temperature environment; and in the common coating environment, the aqueous plastic paint has small possibility of adsorbing environment dust to generate particles.

Owner:WENZHOU BANGXUAN TECH

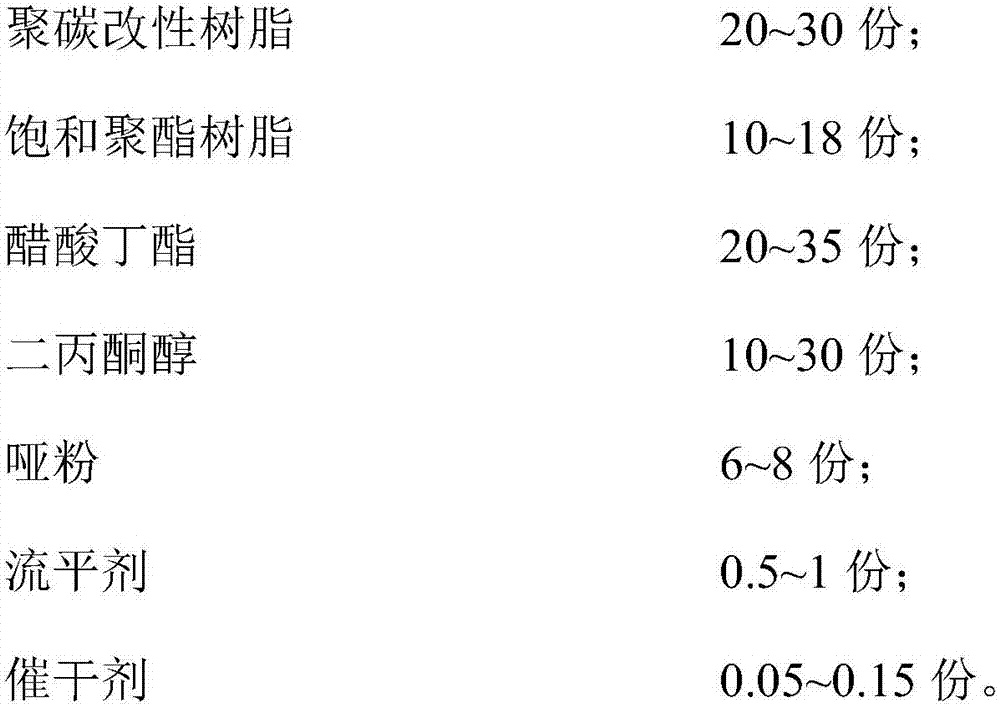

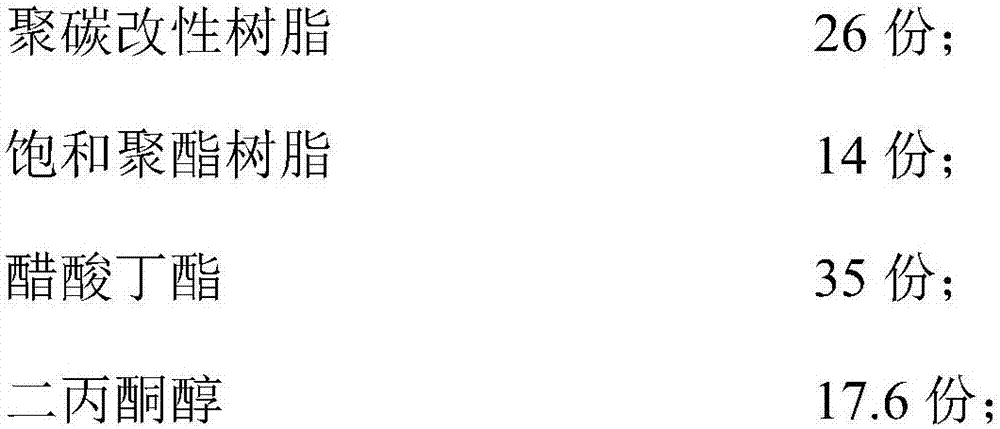

Polycarbon-modified anti-after-tack elastic-feeling paint coating applied to spray coating as well as preparation method and application thereof

InactiveCN107118677AGood touchGood anti-stickinessSiccativesPolyester coatingsDiacetone alcoholButyl acetate

The invention relates to a polycarbon-modified anti-after-tack elastic-feeling paint coating applied to spray coating as well as a preparation method and application thereof. The coating is prepared from the following components in parts by weight: 20-30 parts of polycarbon-modified resin, 10-18 parts of saturated polyester resin, 20-35 parts of butyl acetate, 10-30 parts of diacetone alcohol, 6-8 parts of extinction powder, 0.5-1 part of flatting agents and 0.05-0.15 part of driers. The coating can be applied to spray coating of plastic shells of electronic and electrical appliance products and has the advantages of excellent touch elastic hand feeling and after-tack resistance.

Owner:深圳市美丽华科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com