Water-based self-crosslinking acrylic acid iron oxide red antiseptic paint and preparation method therefor

An acrylic iron red, self-crosslinking technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of high risk factor of storage and transportation, great impact on health, high VOC content, etc., to achieve strong corrosion resistance, small impact on the body, The effect of reducing the content of VOC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

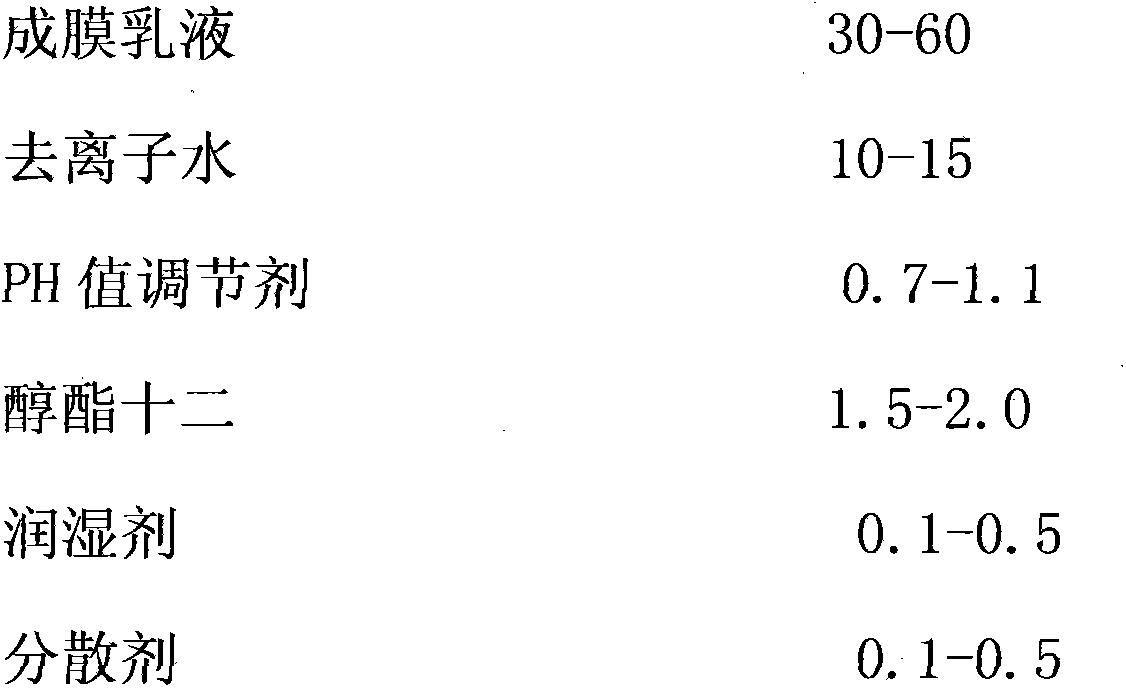

Method used

Image

Examples

Embodiment 1

[0025] Take 10 parts by mass of deionized water and throw it into the dispersion tank, start the agitator to stir at a low speed, and adjust the pH value of the deionized water to about 8 with 0.5 parts by mass of 2-amino-2-methyl-1-propanol. Take 0.1 parts by mass of anionic wetting and dispersing agent, 0.1 part by mass of nonionic wetting and dispersing agent, 0.05 parts by mass of emulsified polysiloxane, and 0.4 parts by mass of anionic hydrophobically modified acrylic alkali-swellable thickener and add them to the dispersion tank , stirring at a low speed (controlled at 300r / min) for 5-10 minutes, then adding 7 parts by mass of iron oxide red, 8 parts by mass of 1500 mesh mica powder, 8 parts by mass of zinc calcium phosphate, 8 parts by mass of ultrafine active barium sulfate, 2 Parts by mass of 800 mesh talcum powder, 1 part by mass of zinc phosphate and 0.1 part by mass of fumed silica, washing machine with a small amount of deionized water, increase the stirring speed...

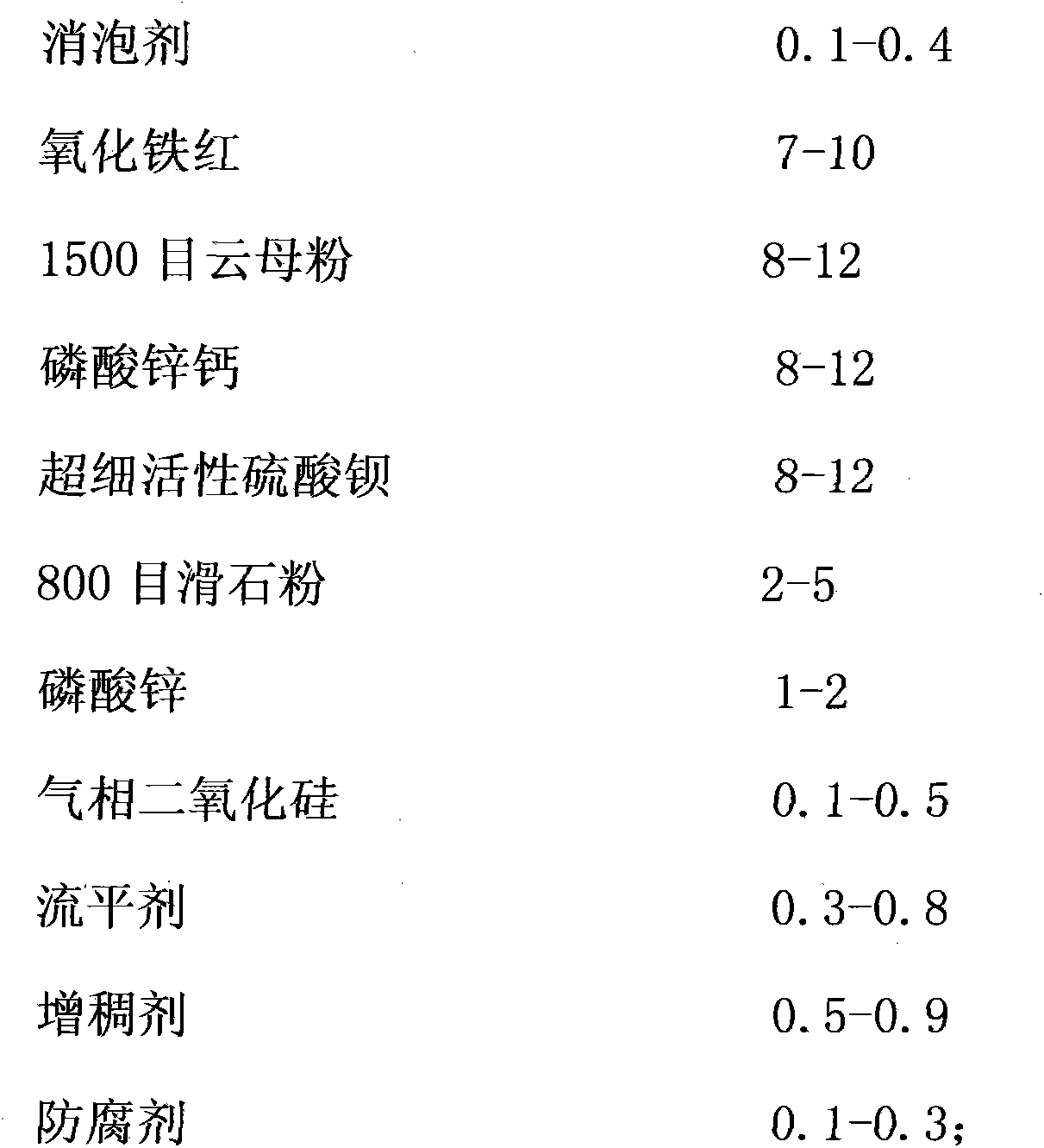

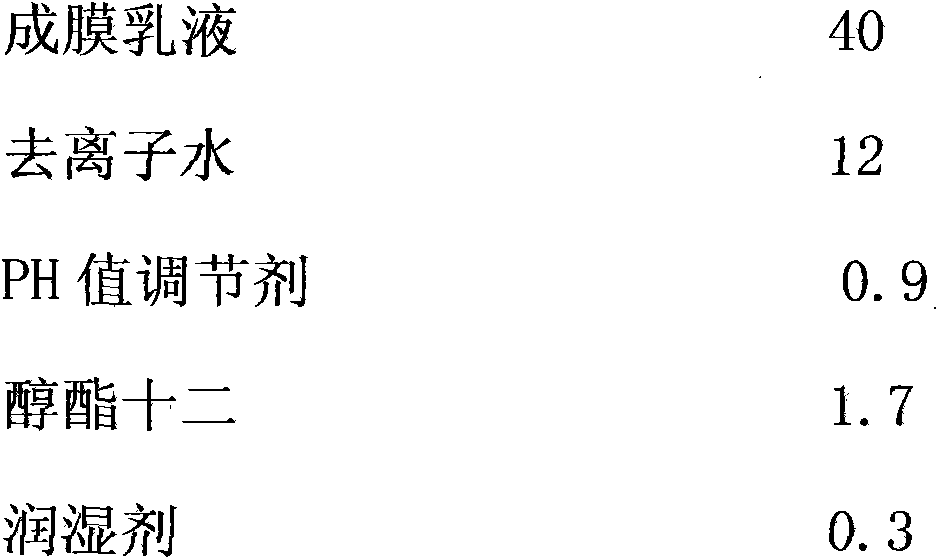

Embodiment 2

[0030] Take 12 parts by mass of deionized water and throw it into the dispersion tank, start the agitator to stir at low speed, and adjust the pH value of the deionized water to about 8.2 with 0.6 parts by mass of 2-amino-2-methyl-1-propanol. Add 0.3 parts by mass of anionic wetting and dispersing agent, 0.3 parts by mass of nonionic wetting and dispersing agent, 0.1 part by mass of emulsified polysiloxane, and 0.3 parts by mass of anionic hydrophobically modified acrylic alkali swelling thickener into the dispersion tank , low-speed stirring (controlled at 300r / min) for 5-10 minutes, then add 8 parts by mass of iron oxide red, 10 parts by mass of 1500 mesh mica powder, 10 parts by mass of zinc calcium phosphate, 10 parts by mass of ultrafine active barium sulfate, 3 Parts by mass of 800 mesh talcum powder, 1.5 parts by mass of zinc phosphate and 0.3 parts by mass of fumed silica, washing machine with a small amount of deionized water, increase the stirring speed so that the pe...

Embodiment 3

[0035] Take 15 parts by mass of deionized water and throw it into the dispersion tank, start the agitator to stir at a low speed, and adjust the pH value of the deionized water to about 9 with 0.7 parts by mass of 2-amino-2-methyl-1-propanol. Add 0.5 parts by mass of anionic wetting and dispersing agent, 0.5 parts by mass of nonionic wetting and dispersing agent, 0.2 parts by mass of emulsified polysiloxane, and 0.6 parts by mass of anionic hydrophobically modified acrylic alkali swelling thickener into the dispersion tank , stirring at a low speed (controlled at 300r / min) for 5-10 minutes, then adding 10 parts by mass of iron oxide red, 12 parts by mass of 1500 mesh mica powder, 12 parts by mass of zinc calcium phosphate, 12 parts by mass of ultrafine active barium sulfate, 5 parts by mass Parts by mass of 800 mesh talcum powder, 2 parts by mass of zinc phosphate and 0.5 part by mass of fumed silica, washing machine with a small amount of deionized water, increase the stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com