A kind of anti-adhesive water-based acrylic emulsion and its preparation method and application

A water-based acrylic and emulsion technology, applied in the field of polymers, can solve the problems of limited application, hot stickiness, cold brittleness, etc., and achieve the effects of simple preparation method, easy temperature control, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

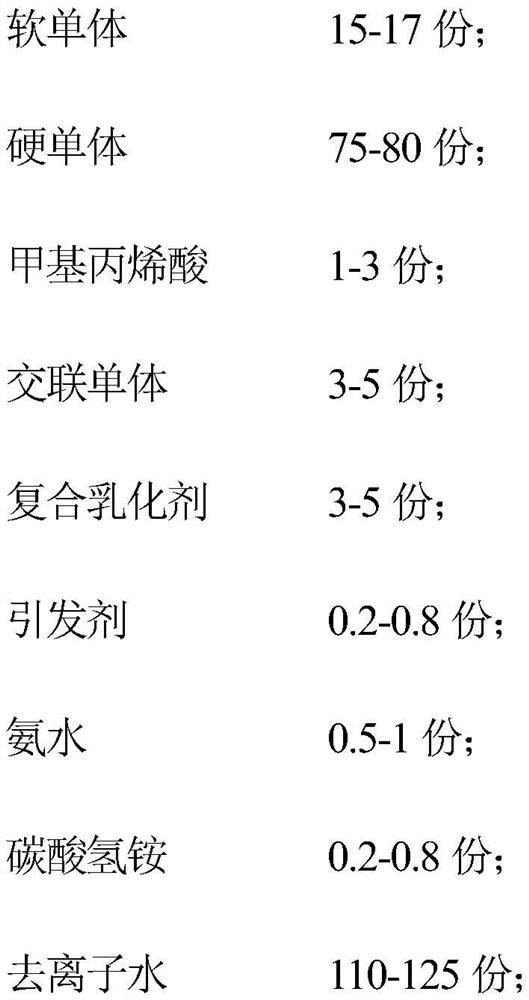

Method used

Image

Examples

preparation example Construction

[0040] A preparation method of an anti-adhesive water-based acrylic emulsion, comprising the following steps:

[0041] (1) Add the compound emulsifier into the deionized water, after stirring evenly, add the soft monomer, methacrylic acid, hard monomer and cross-linking monomer and stir for more than 30 minutes;

[0042] (2) Add the initiator and ammonium bicarbonate into deionized water and stir evenly;

[0043] (3) Take another compound emulsifier and add it to deionized water, start stirring, raise the temperature to 80-85°C, then add the initiator and 4% of the pre-emulsion prepared in step (1) in sequence, and after the reaction starts, add the step (2) The prepared solution and the pre-emulsion prepared in the remaining step (1), the dropwise addition time is 1.5-3h, after the dropwise addition is completed, continue to react for 1-3h, cool down to 30-45°C, adjust the pH to 7-9, Finally, the aqueous acrylic emulsion was obtained by filtration.

[0044] Application of t...

Embodiment 1

[0046] A kind of anti-adhesive water-based acrylic emulsion of the present invention, its formula is shown in Table 1.

[0047] A kind of preparation method of anti-sticking back water-based acrylic emulsion of the present invention, comprises the following steps:

[0048] (1) Add 0.73g of sodium dodecyl diphenyl ether disulfonate and 0.45g of nonionic emulsifier A-980 into 77.50g of deionized water. After stirring evenly, add 15g of butyl acrylate and 1g of methacrylic acid , 75g of methyl methacrylate, 1.08g of hydroxyethyl methacrylate, 1.27g of N-methylolacrylamide, 0.76g of vinyltriethoxysilane, stirring for 30min;

[0049] (2) Add 0.15 parts of ammonium persulfate and 0.20 g of ammonium bicarbonate into 5.50 g of deionized water, and stir evenly;

[0050] (3) Take another 0.4g of sodium dodecyl diphenyl ether disulfonate, 0.33 parts of nonionic emulsifier A-980 and 1.22 parts of nonionic emulsifier acetylene glycol (surfadol 541H), and add them to 27g of deionized In w...

Embodiment 2

[0053] A kind of anti-adhesive water-based acrylic emulsion of the present invention, its formula is shown in Table 1.

[0054] A kind of preparation method of anti-sticking back water-based acrylic emulsion of the present invention, comprises the following steps:

[0055] (1) Add 1.73g of sodium dodecyl diphenyl ether disulfonate and 0.95g of nonionic emulsifier A-980 into 80.50g of deionized water. After stirring evenly, add 16.05g of butyl acrylate, methacrylic acid 2.19g, methyl methacrylate 77.88g, ethylene glycol dimethacrylate 1.74g, N-methylolacrylamide 1.04g, vinyltriethoxysilane 1.22g, stir for 30min;

[0056] (2) Add 0.45g of ammonium persulfate and 0.49g of ammonium bicarbonate into 7.50g of deionized water, and stir evenly;

[0057] (3) Take another 0.4g of sodium dodecyl diphenyl ether disulfonate, 0.83 parts of nonionic emulsifier A-980 and 0.02g of nonionic emulsifier acetylene glycol (surfadol 541H), and add it to 30g of deionized In water, start stirring, h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com