A high-performance water-based environmentally friendly plastic runway

A plastic runway, high-performance technology, applied in the direction of roads, roads, coatings, etc., can solve problems such as air pollution, body poisoning, and inability to cure, achieve excellent weather resistance and anti-sticking, solve environmental problems, and permanent flexibility miscibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

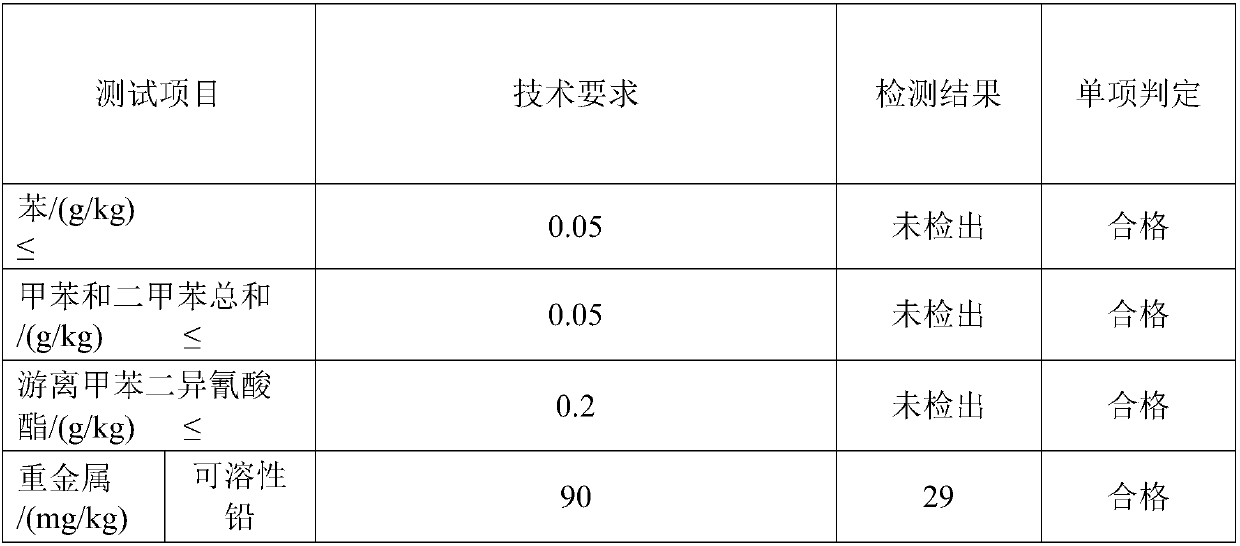

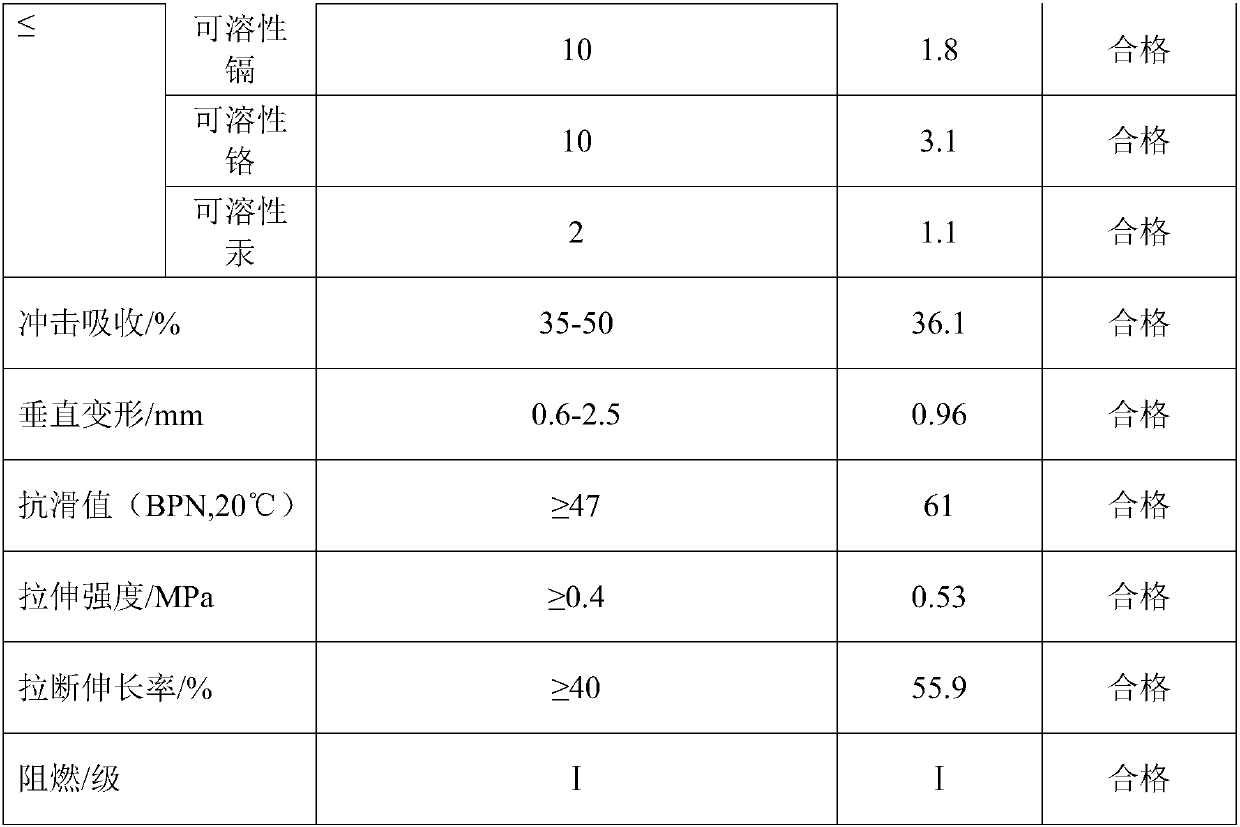

Embodiment 1

[0056] A high-performance water-based environmentally friendly plastic runway, from bottom to top: lime soil 30cm, graded crushed stone 25cm, cement stone powder stabilization layer 15cm, asphalt concrete 9cm, water-based plastic runway surface layer thickness 2mm, water-based plastic runway buffer layer The thickness is 2mm, and the thickness of the bottom layer of the high water-based plastic runway is 9mm. Among them, the graded crushed stone is composed of 20mm crushed stone, 15mm crushed stone, 5mm crushed stone, and stone powder according to a certain ratio. The cement stone powder stable layer is 6% cement stone powder stable layer. The bottom layer of the water-based plastic runway is water-based primer and black plastic particles. It is prepared according to the ratio of 1:5. The buffer layer of water-based plastic runway is made of water-based high-elastic glue and elastic plastic powder. The mixture of elastic plastic microspheres is prepared according to the ratio o...

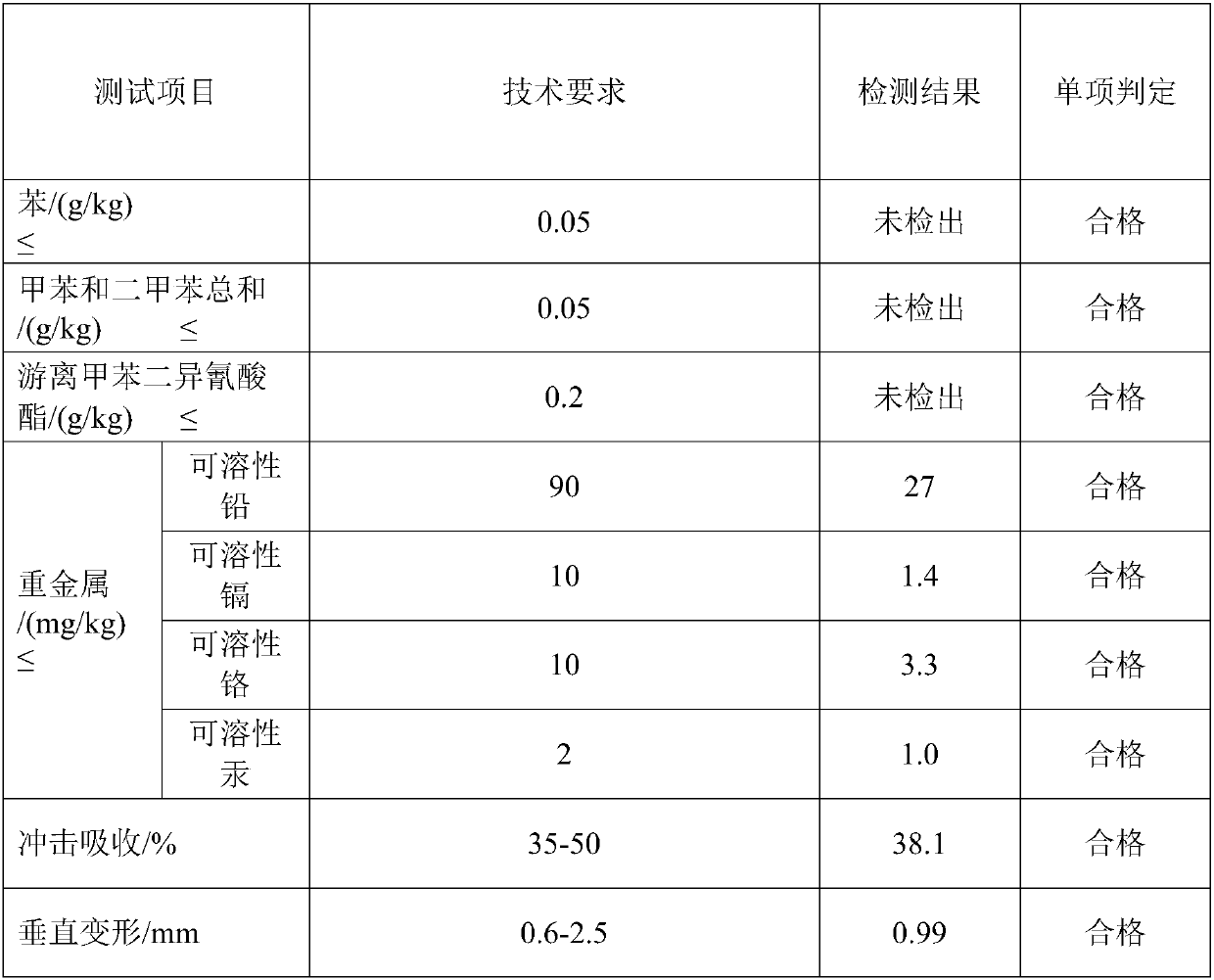

Embodiment 2

[0074] A high-performance water-based environmentally friendly plastic runway, from top to bottom is a water-based environmentally friendly plastic layer, asphalt concrete layer, cement stone powder stabilization layer, graded crushed stone and lime soil, in which the water-based environmentally friendly plastic layer is a water-based environmentally friendly plastic layer arranged in sequence from top to bottom. Plastic runway surface layer, water-based plastic runway buffer layer and water-based plastic runway bottom layer. The cement stone powder stabilization layer is 30cm thick, and the mass ratio of cement to aggregate is 6:100. Graded crushed stones are used with a mass ratio of 1:1:1 from crushed stones with particle sizes of 25mm, 15mm, and 6mm. The thickness of the surface layer of the water-based plastic runway is 3mm, the thickness of the buffer layer of the water-based plastic runway is 2mm, and the thickness of the bottom layer of the water-based plastic runway i...

Embodiment 3

[0091] A high-performance water-based environmentally friendly plastic runway, from top to bottom is a water-based environmentally friendly plastic layer, asphalt concrete layer, cement stone powder stabilization layer, graded crushed stone and lime soil, in which the water-based environmentally friendly plastic layer is a water-based environmentally friendly plastic layer arranged in sequence from top to bottom. Plastic runway surface layer, water-based plastic runway buffer layer and water-based plastic runway bottom layer. The cement stone powder stabilization layer is 30cm thick, and the mass ratio of cement to aggregate is 6:100. Graded crushed stones are used with a mass ratio of 1:1:1 from crushed stones with particle sizes of 30mm, 20mm, and 10mm. The thickness of the surface layer of the water-based plastic runway is 2mm, the thickness of the buffer layer of the water-based plastic runway is 3mm, and the thickness of the bottom layer of the water-based plastic runway ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com