Water-based electrostatic finishing paint and preparation method thereof

An electrostatic and topcoat technology, applied in the coating and other directions, can solve the problems of water-based electrostatic topcoat being easy to sag and the painting effect is not good, and achieves a simple and convenient preparation method, good painting effect and good anti-sticking effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The second aspect of the embodiment of the present application provides a method for preparing a water-based electrostatic topcoat, comprising the following steps:

[0050] S01. Provide each component according to the water-based electrostatic topcoat;

[0051] S02. Performing a first mixing treatment on the first aqueous emulsion, the second aqueous emulsion, and the rheology additive to obtain a first mixture;

[0052] S03. Performing a second mixing treatment on the first mixture and the film-forming aid to obtain a second mixture;

[0053] S04. The deionized water and the thixotropic agent are subjected to a third mixing treatment to obtain a third mixture, which is placed overnight for use;

[0054] S05. Perform the fourth mixing treatment of the second mixture, the third mixture, other additives and deionized water to obtain a water-based electrostatic topcoat. The preparation method of the water-based electrostatic topcoat provided by the second aspect of the a...

Embodiment 1

[0067] Water-based electrostatic topcoat and preparation method thereof

[0068] Water-based electrostatic topcoat

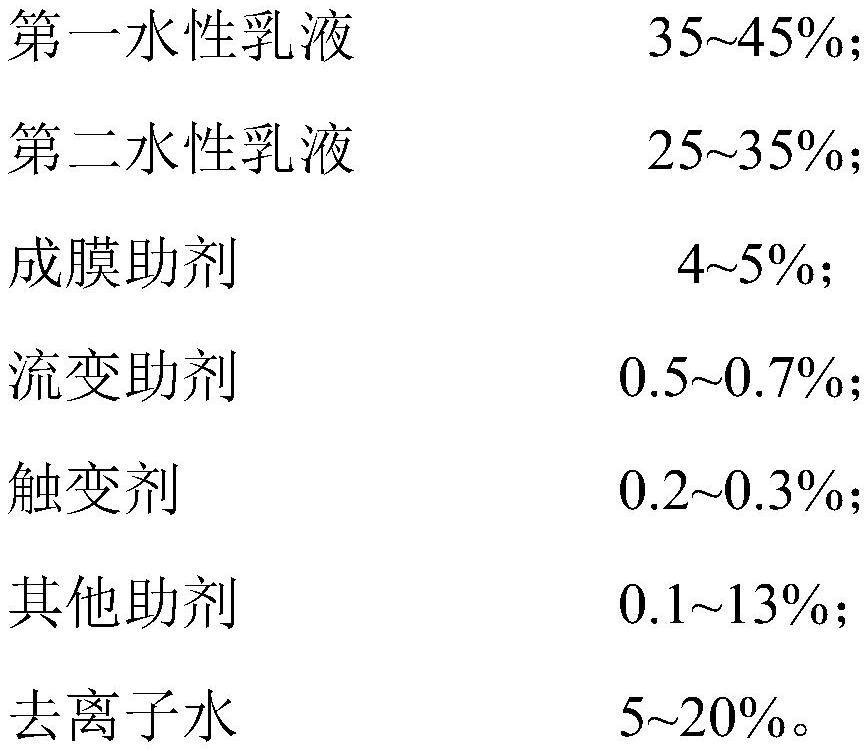

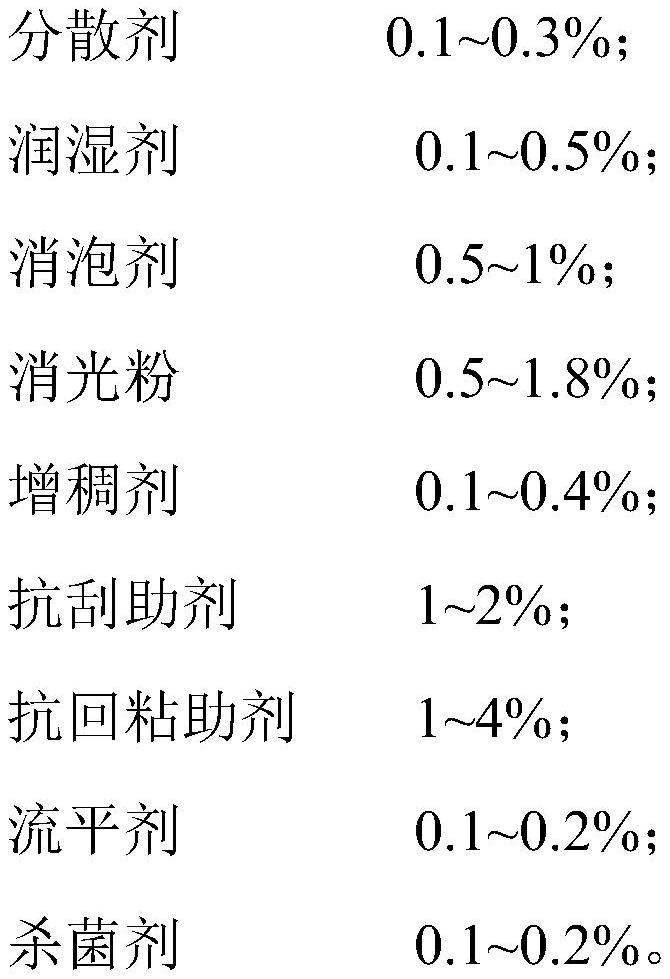

[0069] Based on the total weight of the water-based electrostatic topcoat as 100%, it includes the following components in the following weight percentages:

[0070]

[0071] Among them, the first aqueous emulsion is selected from ROSHIELD 3311, the second aqueous emulsion is selected from SETAQUA6716, the film-forming aid is selected from the mixture of DPNB and DPM in a weight ratio of 1:1, and the rheology additive is selected from Elements RHEOLATE 299. The variable agent is selected from LAPONITE RD,

[0072]

[0073]

[0074] Preparation method of water-based electrostatic topcoat

[0075] Each component of the water-based electrostatic topcoat of embodiment 1 is provided,

[0076] Mix the first aqueous emulsion, the second aqueous emulsion, the rheological additive, the dispersant, the wetting agent, the defoamer, the matting powder, and th...

Embodiment 2

[0081] Water-based electrostatic topcoat and preparation method thereof

[0082] Water-based electrostatic topcoat

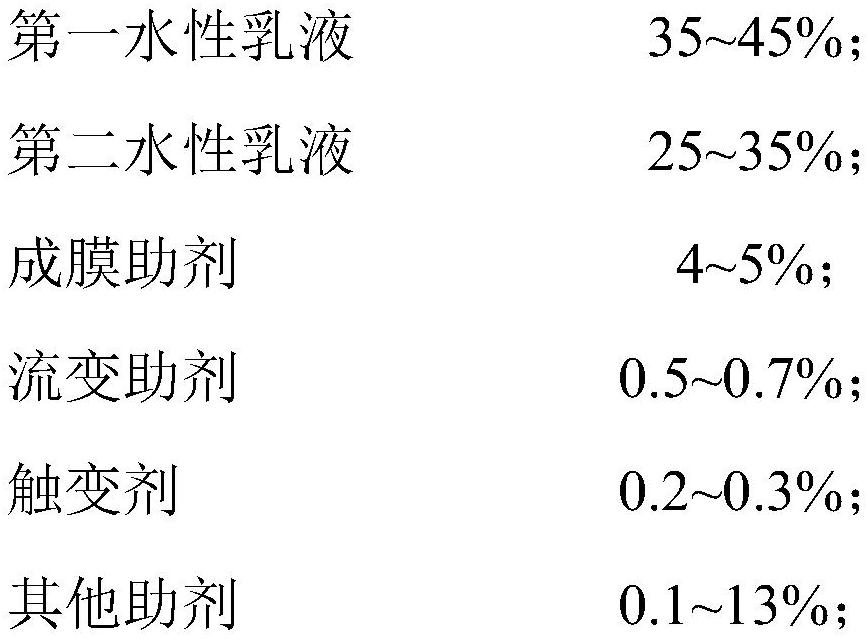

[0083] Based on the total weight of the water-based electrostatic topcoat as 100%, it includes the following components in the following weight percentages:

[0084]

[0085] Among them, the first aqueous emulsion is selected from ROSHIELD 3311, the second aqueous emulsion is selected from SETAQUA6716, the film-forming aid is selected from the mixture of DPNB and DPM in a weight ratio of 1:1, and the rheology additive is selected from Elements RHEOLATE 299. The variable agent is selected from LAPONITE RD,

[0086]

[0087]

[0088] Preparation method of water-based electrostatic topcoat

[0089] Each component of the water-based electrostatic topcoat of embodiment 2 is provided,

[0090] Mix the first aqueous emulsion, the second aqueous emulsion, the rheological additive, the dispersant, the wetting agent, the defoamer, the matting powder, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com