Polycarbon-modified anti-after-tack elastic-feeling paint coating applied to spray coating as well as preparation method and application thereof

A viscoelastic, hand-feeling paint technology, applied in polycarbonate coatings, polyester coatings, chemical instruments and methods, etc., can solve the problems of hard hand feeling and high price, and achieve excellent anti-stickiness, good touch elastic feel, and excellent touch Hand feeling and anti-stick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

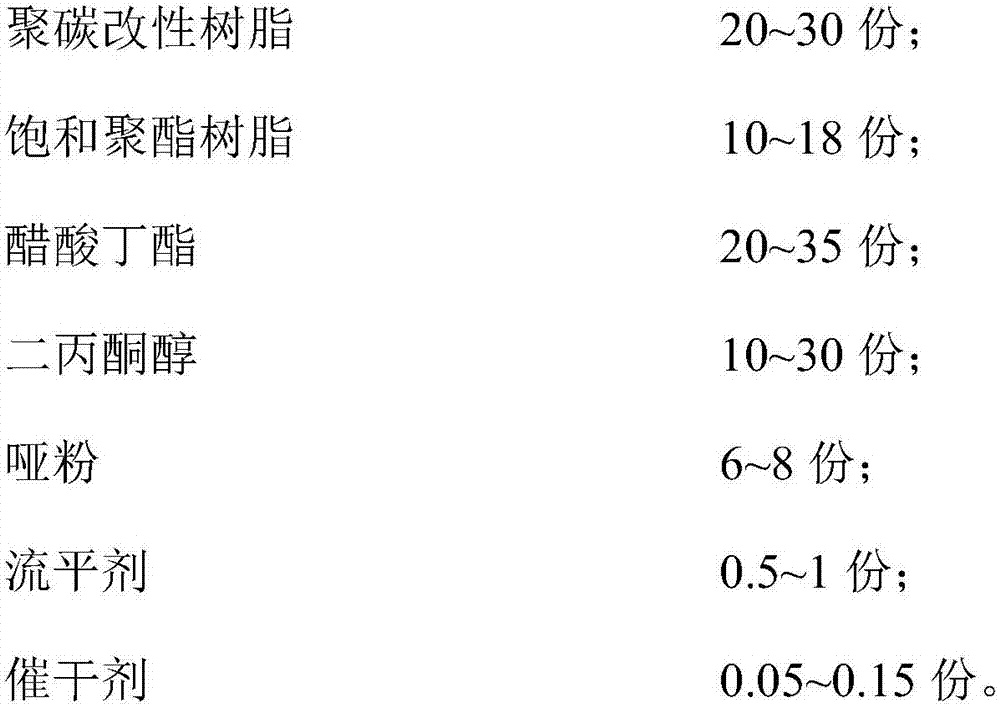

[0038] A polycarbon modified anti-rebound viscoelastic feel paint coating for spraying, which comprises the following components by weight:

[0039]

[0040] The preparation method of the polycarbon modified anti-rebound viscoelastic feel paint coating for spraying is as follows:

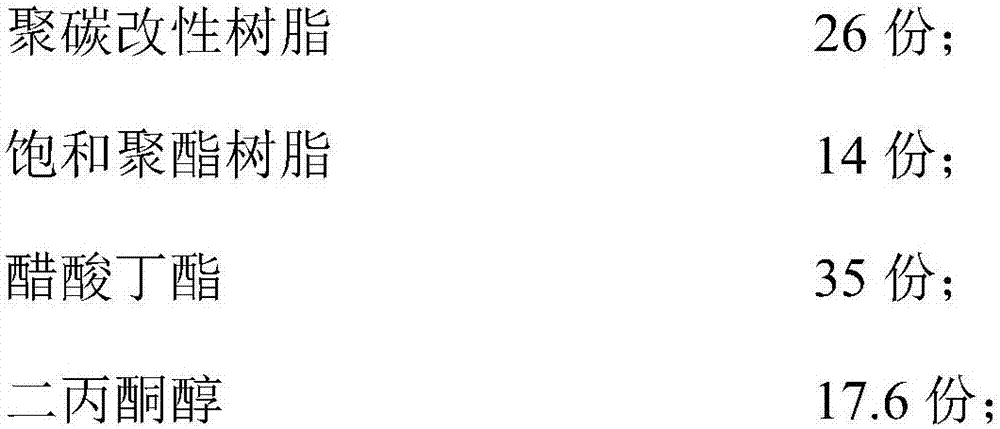

[0041] Get 26 parts (weight) of polycarbon modified resin, its hydroxyl value is 130mgKOH / g, solid content is equal to or greater than 40%; 14 parts (weight) of saturated polyester resins, its hydroxyl value is 50mgKOH / g, solid content is equal to or greater than Greater than 40%; add 0.5 part (weight) of leveling agent again, wherein leveling agent selects BYK-323 type siloxane for use, after the formed mixture is dispersed at a low speed of 700r / min, add 35 parts of butyl acetate solvent ( weight), then stirred for 10 minutes, then added 6.8 parts (weight) of dull powder OK520, dispersed at a high speed of 1300r / min to a fineness below 5 μm, added 17.6 parts (weight) of diacetone alcohol, and f...

Embodiment 2

[0043] A polycarbon modified anti-rebound viscoelastic feel paint coating for spraying, which comprises the following components by weight:

[0044]

[0045]

[0046] The preparation method of the polycarbon modified anti-rebound viscoelastic feel paint coating for spraying is as follows:

[0047]Get 30 parts (weight) of polycarbon modified resin, its hydroxyl value is 130mgKOH / g, solid content is equal to or greater than 40%; 10 parts (weight) of saturated polyester resin, its hydroxyl value is 50mgKOH / g, solid content is equal to or greater than Greater than 40%; add 0.5 part (weight) of leveling agent again, wherein leveling agent selects BYK-323 type siloxane for use, after the mixture formed is uniformly dispersed at a low speed of 600r / min, add 30 parts of butyl acetate solvent ( weight), then stirred for 10 minutes, then added 6.8 parts of dumb powder OK520, dispersed at a high speed of 1250r / min to a fineness below 5 μm, added 22.6 parts (weight) of diacetone alc...

Embodiment 3

[0049] A polycarbon modified anti-rebound viscoelastic feel paint coating for spraying, which comprises the following components by weight:

[0050]

[0051] The preparation method of the polycarbon modified anti-rebound viscoelastic feel paint coating for spraying is as follows:

[0052] Get 23 parts (weight) of polycarbon modified resin, its hydroxyl value is 130mgKOH / g, solid content is equal to or greater than 40%; Saturated polyester resin 12.5 parts (weight), its hydroxyl value is 50mgKOH / g, solid content is equal to or greater than Greater than 40%; add 0.5 part (weight) of leveling agent again, wherein leveling agent selects BYK-323 type siloxane for use, after the mixture formed is uniformly dispersed at a low speed of 750r / min, add 32 parts of butyl acetate solvent ( weight), then stirred for 10 minutes, then added 6.8 parts of dumb powder OK520, added 20.6 parts (weight) of diacetone alcohol, dispersed at a high speed of 1400r / min to a fineness below 5 μm, and fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com