A kind of ultra-soft and ultra-thin composite rock slice and its preparation method

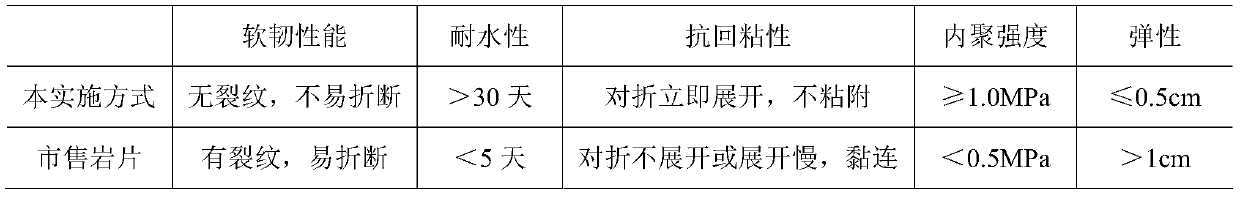

A composite rock slice, ultra-thin technology, applied in the direction of powder coating, coating, etc., can solve the problems of high liquid absorption rate, high stickiness of rock slice, and water resistance, etc., and achieve excellent stickback resistance, excellent coating performance, and good Anti-friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0030] An ultra-soft and ultra-thin composite rock slice, said composite rock slice contains the following raw materials in parts by weight: 500 parts of emulsion, 2 parts of defoamer, 3 parts of color paste, 3 parts of dispersant, and 500 parts of powder raw material , 2 parts of thickener, 1 part of bentonite, 10 parts of functional auxiliary agent A, 3 parts of functional auxiliary agent B, and 10 parts of water. Add the weighed substances into the container in turn under the condition of stirring, the stirring speed is 500-600 rpm, the stirring time is 30-35min, and the rock flake slurry is obtained after stirring evenly, which is ready for use;

[0031] Step 2. Start the flake film-forming drying equipment, first apply the release agent on the conveyor belt of the rock flake film-forming drying equipment, then scrape and coat the rock flake slurry prepared in step 1 on the conveyor belt, and enter the rock flake film-forming drying equipment with the conveyor belt Drying ...

specific Embodiment approach 2

[0039] According to the preparation method of the ultra-soft ultra-thin composite rock slice described in the specific embodiment one, comprising the following steps:

[0040] Step 1. Weigh a certain quality of emulsion, defoamer, color paste, dispersant, powder raw material, thickener, bentonite, functional additive A, functional additive B, and water according to the parts by weight, and weigh The good materials are added to the container in turn under the condition of stirring, the stirring speed is 300-350 rpm, the stirring time is 45-50min, and the rock flake slurry is obtained after stirring evenly, which is ready for use;

[0041] Step 2. Start the flake film-forming drying equipment, first apply the release agent on the conveyor belt of the rock flake film-forming drying equipment, then scrape and coat the rock flake slurry prepared in step 1 on the conveyor belt, and enter the rock flake film-forming drying equipment with the conveyor belt Drying in the middle, after ...

specific Embodiment approach 3

[0047] An ultra-soft and ultra-thin composite rock slice, which contains the following raw materials in parts by weight: 450 parts of emulsion, 1 part of defoamer, 1 part of color paste, 1 part of dispersant, and 550 parts of powder raw materials , 4 parts of thickener, 2 parts of bentonite, 15 parts of functional auxiliary agent A, 5 parts of functional auxiliary agent B, and 30 parts of water.

[0048] In the ultra-soft and ultra-thin composite rock slice described in this embodiment, the emulsion is a modified water-based acrylic emulsion; the defoamer is a polyether defoamer; the color paste is a water-based paint color paste ; The dispersant is an anionic surfactant; the functional auxiliary agent A is polyamide, and the functional auxiliary agent B is isocyanate.

[0049] In the ultra-soft and ultra-thin composite rock slice described in this embodiment, the powder raw material includes 300 parts of heavy calcium carbonate, 200 parts of wollastonite, and 50 parts of mica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com