Modified water-based binder as well as preparation method and application thereof

A water-based binder and modification technology, applied in the field of modified water-based binder and its preparation, can solve the problems of poor stability, low bonding strength and high liquid absorption rate of the water-based binder, and achieve strong alkali resistance. , good dispersion, low liquid absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

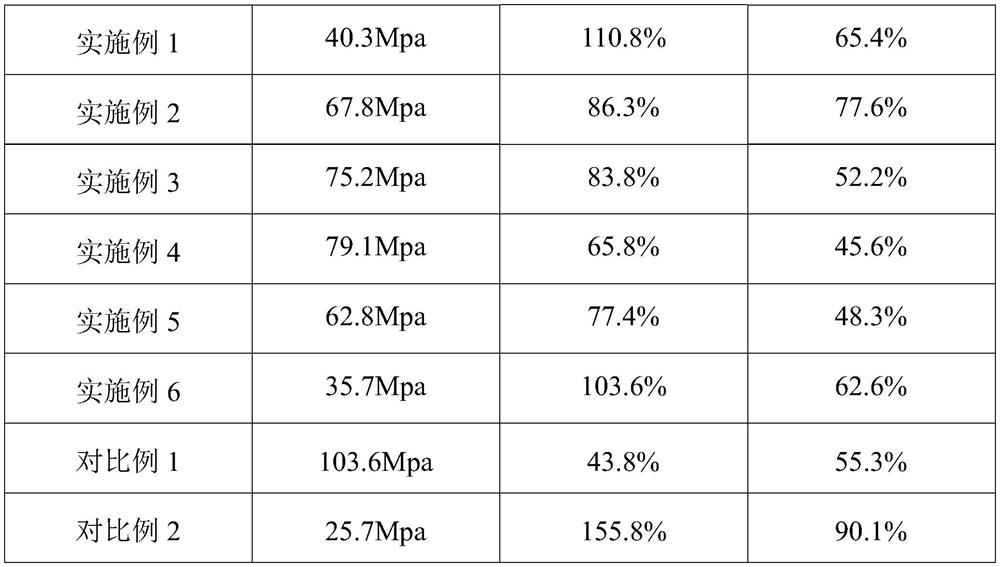

Examples

Embodiment 1

[0041] This embodiment provides a modified water-based binder, which is prepared by the following method:

[0042] (1) Mix 0.8 parts of RAFT reagent, 0.3 parts of initiator, and 50 parts of acrylic monomer and react at 65°C for 12 hours to obtain 50 parts of polyacrylate;

[0043](2) Add 25 parts of p-isooctyl acrylate monomer to the polyacrylate obtained in step (1), and react at 70° C. for 8 hours to obtain acrylic acid and acrylate binary copolymer;

[0044] (3) Add 25 parts of methyl methacrylate monomer and 431 parts of deionized water after dissolving the obtained acrylic acid and acrylate binary copolymer obtained in step (2), and mix for 4 hours at 4500r / min to obtain the modified water-based binder.

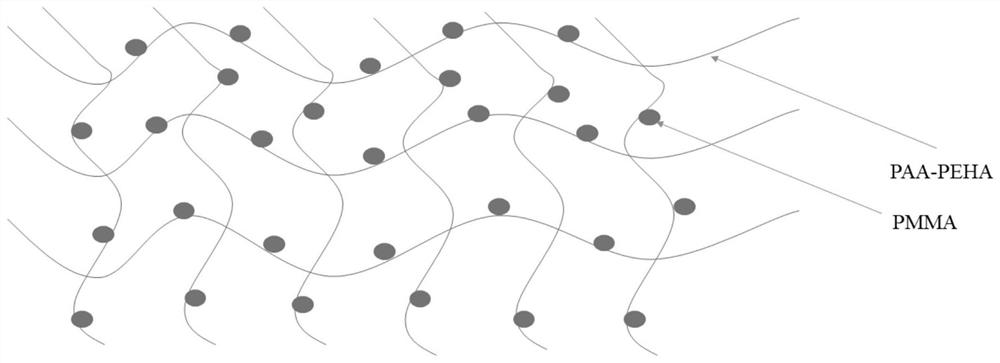

[0045] The schematic diagram of the modified water-based binder is as figure 1 shown.

Embodiment 2

[0047] This embodiment provides a modified water-based binder, which is prepared by the following method:

[0048] (1) Mix 0.6 parts of RAFT reagent, 0.5 parts of initiator, and 50 parts of acrylic monomer and react at 70°C for 15 hours to obtain 50 parts of polyacrylate;

[0049] (2) Add 20 parts of p-isooctyl acrylate monomer to the polyacrylate obtained in step (1), and react at 75°C for 9 hours to obtain acrylic acid and acrylate binary copolymer;

[0050] (3) Add 30 parts of methyl methacrylate monomer and 573 parts of deionized water after dissolving the obtained acrylic acid and acrylate binary copolymer obtained in step (2), and mix for 5 hours at 4000r / min to obtain the modified water-based binder.

Embodiment 3

[0052] The only difference between this embodiment and Example 1 is that the acrylic acid monomer described in step (1) is 55 parts, and the p-isooctyl acrylate monomer described in step (2) is 20 parts, and other conditions and parameters are completely the same as those in Example 1. same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com