Polyvinyl chloride cable material and preparation method thereof

A polyvinyl chloride cable, polyvinyl chloride technology, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problem that the working temperature range cannot fully meet the requirements, and achieve excellent electrical insulation performance, good cold resistance, and improved The effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0023] The polyvinyl chloride cable material provided by this embodiment is composed of 100 parts of polyvinyl chloride, 15 parts of dioctyl sebacate, 20 parts of ethylene-ethyl acrylate copolymer, 4 parts of polyethylene wax, peroxide It consists of 0.2 parts of dihexadecyl dicarbonate, 2 parts of vinyltrimethoxysilane, and 3 parts of dibutyltin dilaurate. Its preparation method is carried out according to the following steps:

[0024] 1. 100 parts of polyvinyl chloride, 15 parts of dioctyl sebacate, 20 parts of ethylene-ethyl acrylate copolymer, 4 parts of polyethylene wax, 3 parts of dibutyltin dilaurate, the components that will contain the above mass parts The mixture is mixed in a high mixer at 120°C for 10 minutes, and the temperature of the kneaded powder is 110-130°C;

[0025] 2. Then make materials in the co-rotating twin-screw with a double length-to-diameter ratio of 48:1, and the temperature of the twin-screw is 140-160°C;

[0026] 3. Deep dehydration and drying...

specific Embodiment 2~18

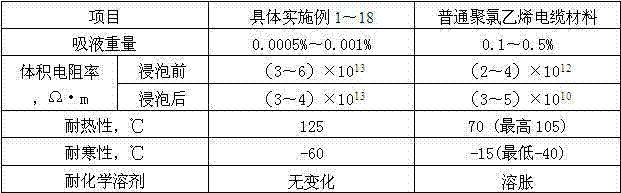

[0030] The polyvinyl chloride cable material provided in this embodiment consists of 100 parts of polyvinyl chloride and the components listed in Table 1 in terms of parts by mass. Calcium-zinc composite heat stabilizer and antioxidant 1010 are added to the mixture in step (a), and the preparation method is the same as that of specific example 1. Among them, component A is dioctyl sebacate, component B is ethylene-ethyl acrylate copolymer, component C is polyethylene wax, component D is dihexadecyl peroxydicarbonate, component E It is vinyltrimethoxysilane, component F is dibutyltin dilaurate, component G is calcium-zinc composite heat stabilizer, and component H is antioxidant 1010.

[0031] Table 1

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com