A kind of modified water-based binder and its preparation method and application

A water-based binder and modification technology, applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the problems of poor stability, low bonding strength and poor stability of water-based binders, and achieve strong alkali resistance, Good dispersion and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

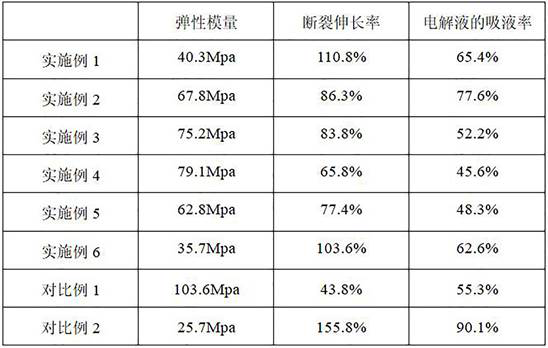

Examples

Embodiment 1

[0041] The present embodiment provides a modified water-based binder, and the modified water-based binder is prepared by the following method:

[0042] (1) Mix 0.8 parts of RAFT reagent, 0.3 parts of initiator, and 50 parts of acrylic monomers and react at 65°C for 12 hours to obtain 50 parts of polyacrylate;

[0043](2) adding 25 parts of isooctyl acrylate monomer to the polyacrylate obtained in step (1), and reacting at 70° C. for 8 hours to obtain a binary copolymer of acrylic acid and acrylate;

[0044] (3) After dissolving the acrylic acid and acrylate binary copolymer obtained in step (2), adding 25 parts of methyl methacrylate monomer and 431 parts of deionized water, and mixing at 4500 r / min for 4 hours to obtain the modified water-based adhesive.

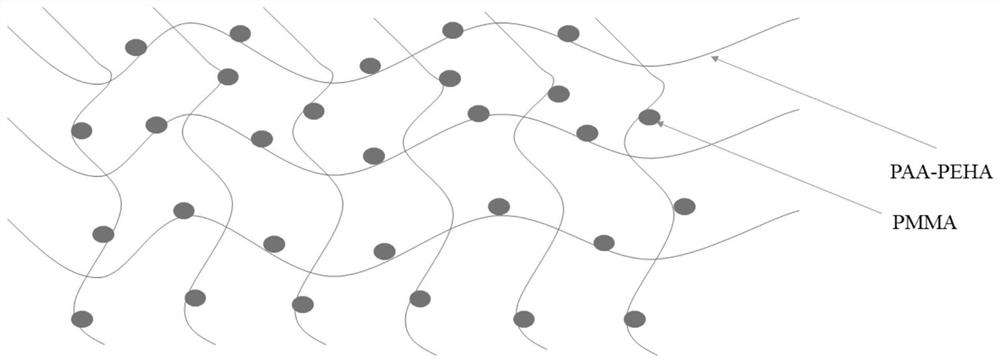

[0045] The schematic diagram of the modified water-based binder is as follows figure 1 shown.

Embodiment 2

[0047] The present embodiment provides a modified water-based binder, and the modified water-based binder is prepared by the following method:

[0048] (1) Mix 0.6 parts of RAFT reagent, 0.5 parts of initiator, and 50 parts of acrylic monomer and react at 70°C for 15 hours to obtain 50 parts of polyacrylate;

[0049] (2) adding 20 parts of isooctyl acrylate monomer to the polyacrylate obtained in step (1), and reacting at 75°C for 9 hours to obtain a binary copolymer of acrylic acid and acrylate;

[0050] (3) After dissolving the acrylic acid and acrylate binary copolymer obtained in step (2), adding 30 parts of methyl methacrylate monomer and 573 parts of deionized water, and mixing at 4000 r / min for 5 hours to obtain the modified water-based adhesive.

Embodiment 3

[0052] The only difference between this example and Example 1 is that the acrylic monomer in step (1) is 55 parts, the isooctyl acrylate monomer in step (2) is 20 parts, and other conditions and parameters are completely the same as in Example 1 same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com