A modified polymer material and its preparation method and application

A polymer material and modification technology, which is applied in the field of modified polymer materials and its preparation, can solve the problems of high technical difficulty, high cost, and difficulty in meeting the requirements of industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

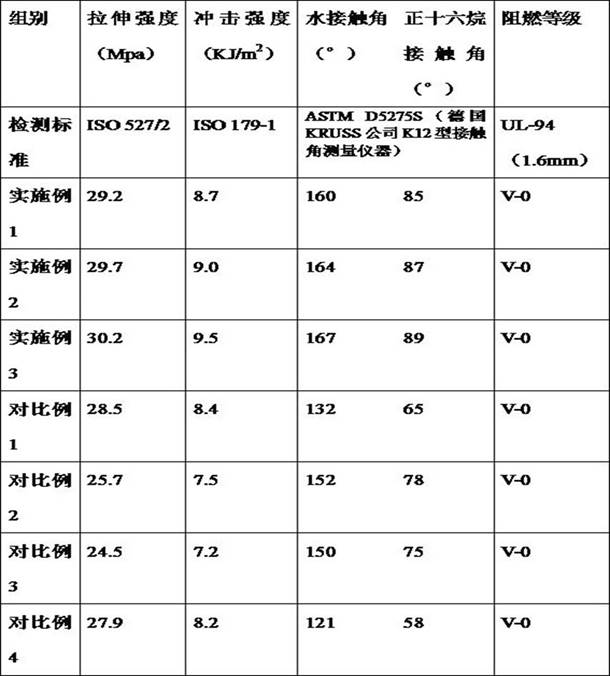

Embodiment 1

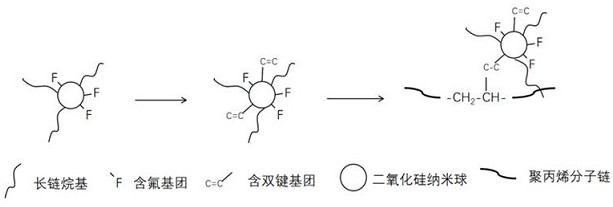

[0031] The present embodiment provides a method for preparing a modified polymer material, comprising the following steps:

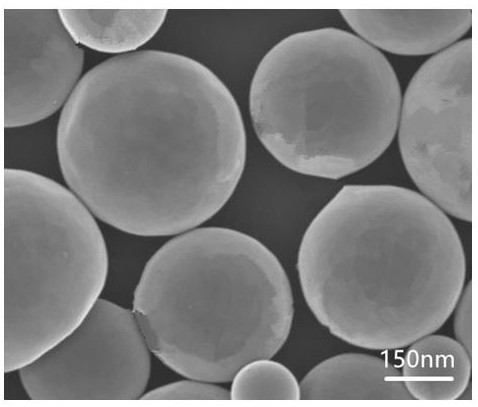

[0032] S1. SiO with fluorine and long alkyl chains on the surface 2 Preparation of nano-microspheres: 10 g of N-β(aminoethyl)-γ-aminopropyltriethoxysilane, 2 g of 1H,1H,2H,2H-perfluorodecyltrimethoxysilane and 1 g of dodecyl Trimethoxysilane was dissolved in 50 mL of dichloromethane, mixed uniformly to obtain an oil phase; 30 mL of an aqueous solution containing 2wt% Tween-80 was added dropwise to the oil phase, emulsified at 10,000 r / min for 3 minutes, and reacted at 500 r / min. 5h, centrifuged, washed, and dried to obtain SiO containing fluorine and long-chain alkyl chains on the surface 2 Nanospheres;

[0033] S2. Modified SiO 2 Preparation of nano-microspheres: 10 g of SiO containing fluorine and long-chain alkyl chains on the surface prepared in step S1 2 The nanospheres were added to 20 mL of ethanol aqueous solution of silane coupling agent A15...

Embodiment 2

[0036] The present embodiment provides a method for preparing a modified polymer material, comprising the following steps:

[0037] S1. SiO with fluorine and long alkyl chains on the surface 2 Preparation of nanospheres: Dissolve 10 g of γ-aminopropyltrimethoxysilane, 5 g of 1H, 1H, 2H, 2H-perfluorooctyltriethoxysilane and 3 g of hexadecyltrimethylsiloxane in 50 mL In petroleum ether, mix well to obtain an oil phase; add 30 mL of an aqueous solution containing 5wt% sodium hexadecyl sulfate dropwise to the oil phase, emulsify at 15000r / min for 7min, react at 1000r / min for 7h, centrifugally wash, and dry , to obtain SiO containing fluorine and long alkyl chains on the surface 2 Nanospheres;

[0038] S2. Modified SiO 2 Preparation of nano-microspheres: 10 g of SiO containing fluorine and long-chain alkyl chains on the surface prepared in step S1 2 Nano-microspheres were added to 50 mL of ethanol aqueous solution of silane coupling agent KH570 (the content of silane coupling a...

Embodiment 3

[0041] The present embodiment provides a method for preparing a modified polymer material, comprising the following steps:

[0042] S1. SiO with fluorine and long alkyl chains on the surface 2 Preparation of nano-microspheres: 10g N-β(aminoethyl)-γ-aminopropylmethyldimethoxysilane, 3.5g 1H,1H,2H,2H-perfluorooctyltrimethoxysilane and 2g ten The octaalkylsiloxane was dissolved in 50 mL of ethyl acetate, and mixed uniformly to obtain an oil phase; 30 mL of an aqueous solution containing 3.5wt% sodium octadecyl sulfonate was added dropwise to the oil phase, and emulsified at 12500 r / min for 5 min. The reaction was carried out at 700 r / min for 6 h, centrifuged, washed, and dried to obtain SiO containing fluorine and long-chain alkyl chains on the surface. 2 Nanospheres;

[0043] S2. Modified SiO 2 Preparation of nano-microspheres: 10 g of SiO containing fluorine and long-chain alkyl chains on the surface prepared in step S1 2 Nano-microspheres were added to 35 mL of ethanol aqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com