Hydrophilic ink for intaglio printing on surfaces of aluminum foils and preparation method thereof

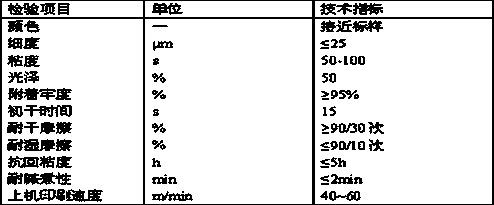

A water-based ink and gravure printing technology, which is applied in the field of printing ink, can solve the problems that the technical indicators of water-based ink are difficult to meet the requirements, and achieve the effects of good adhesion fastness, good water resistance, and fast drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

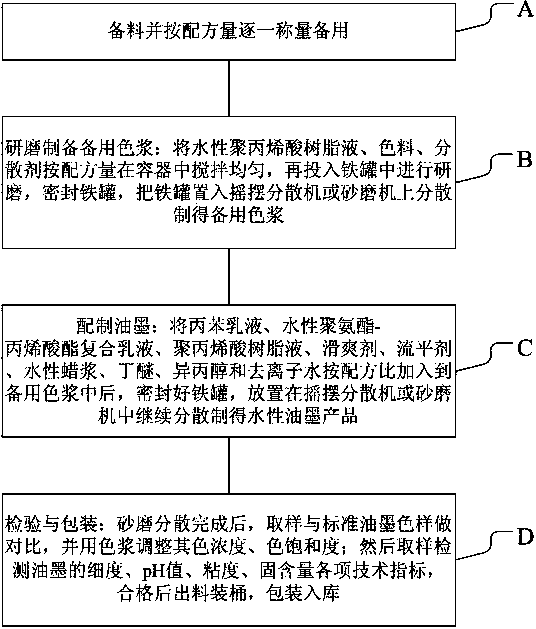

[0042] see figure 1 , the present invention also provides the preparation method of above-mentioned printing ink, the preparation method of described food, pharmaceutical packaging water-based aluminum foil printing ink comprises the following steps:

[0043] Step A: material preparation and weighing;

[0044] The specific operation is: synthesizing or purchasing various raw materials specified above, and weighing them one by one according to the specified weight parts for future use.

[0045] Step B: Grinding to prepare color paste: Stir the water-based polyacrylic resin liquid, colorant, and dispersant in the container according to the formula amount, and then put it into an iron can for grinding, seal the iron can, put the iron can into a swing disperser or Disperse on a sand mill to prepare a spare color paste.

[0046] In the present invention, a certain amount of glass beads are added into the iron tank for ball milling or sand milling; the time for dispersing on a swi...

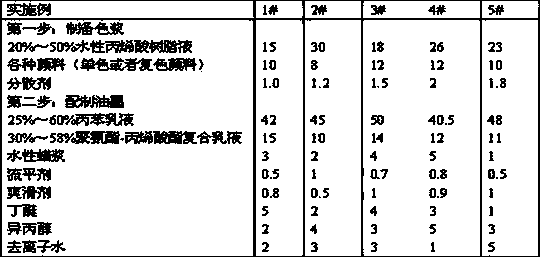

Embodiment 1

[0055]Weigh 15 parts of water-based acrylic resin solution with a solid content of 20% to 50%, 10 parts of white pigment, and 1 part of dispersant, add them to the container in turn and stir evenly, and then transfer to the iron for ball milling (or sand milling) treatment. Put a certain amount of glass beads (or steel balls) into the tank, seal the iron tank, put the iron tank into a swing disperser (or sand mill) and disperse for 2 to 3 hours, and wait until the fineness reaches below 15 μm, the standby color can be prepared. pulp.

[0056] Then add 42 parts of 25% to 60% propylbenzene emulsion, 15 parts of 30% to 58% water-based polyurethane-acrylate composite emulsion, 3 parts of water-based wax paste, 0.5 parts of leveling agent, 0.8 parts of slip agent, 5 parts of Add butyl ether, 2 parts of isopropanol and 2 parts of deionized water to the above-mentioned spare color paste, seal the tin can again, place it in a swing disperser (or sand mill) and continue to disperse for...

Embodiment 2

[0058] Weigh 30 parts of water-based acrylic resin solution with a solid content of 20% to 50%, 8 parts of black pigment, and 1.2 parts of dispersant, add them to the container in turn and stir evenly, and then transfer to the iron for ball milling (or sand milling) treatment. Put a certain amount of glass beads (or steel balls) into the tank, seal the iron tank, put the iron tank into a swing disperser (or sand mill) and disperse for 2 to 3 hours, and wait until the fineness reaches below 15 μm, the standby color can be prepared. pulp.

[0059] Then add 45 parts of 25% to 60% propylbenzene emulsion, 10 parts of 30% to 58% water-based polyurethane-acrylate composite emulsion, 2 parts of water-based wax slurry, 1 part of leveling agent, 0.5 part of slip agent, 2 parts of Add butyl ether, 4 parts of isopropanol and 3 parts of deionized water to the above-mentioned spare color paste, seal the tin can again, place it in a swing disperser (or sand mill) and continue to disperse for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com