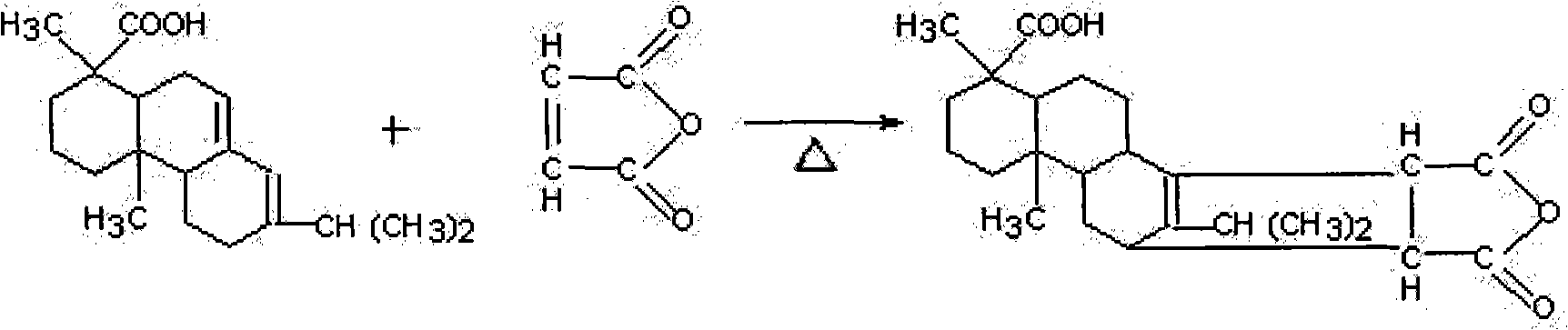

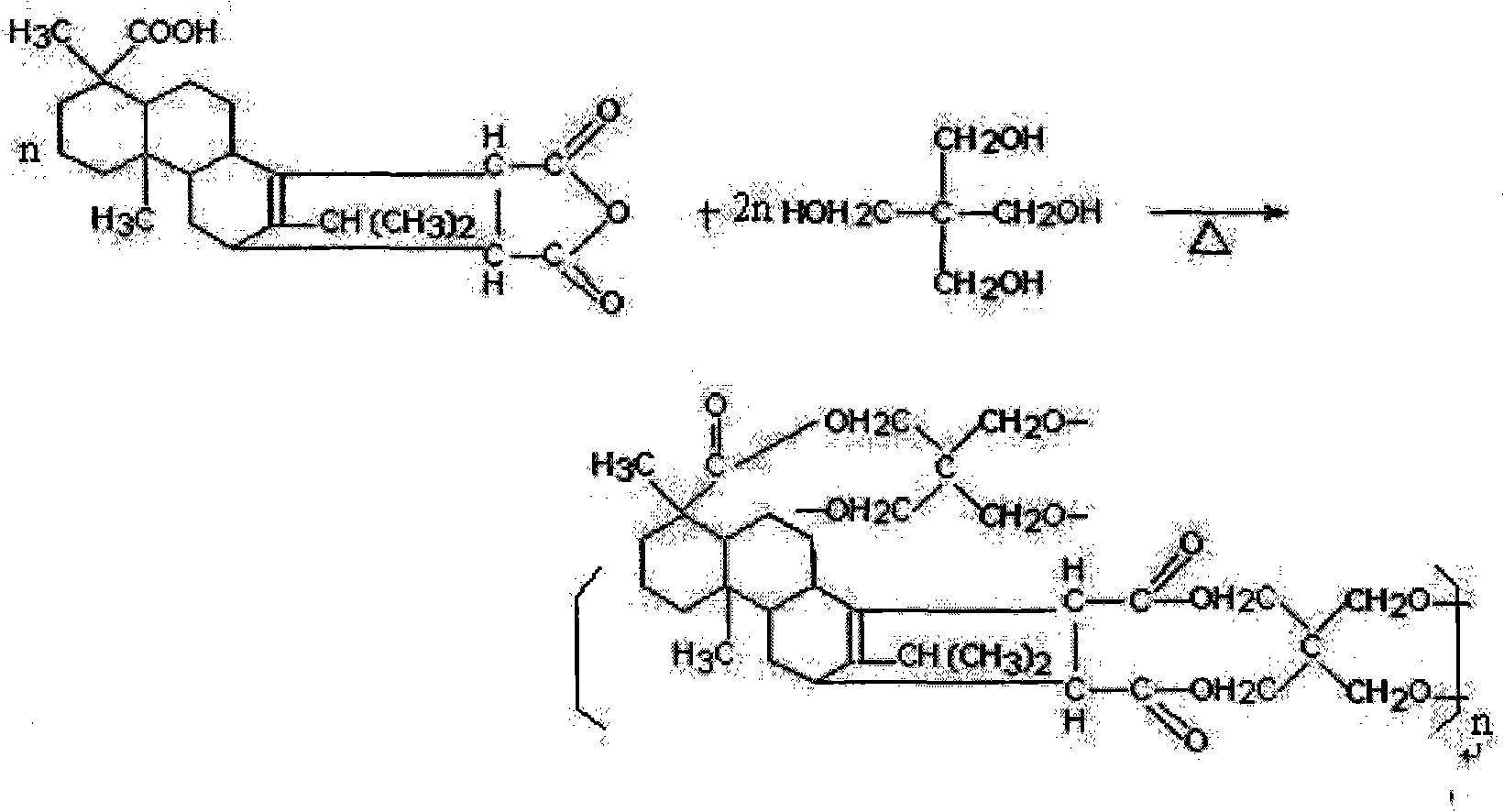

Production method of abietic maleic anhydride resin

A technology of rosin maleic anhydride and maleic anhydride, which is applied in the production field of rosin maleic anhydride resin, can solve the problem of inability to effectively control the molecular weight range, failure to meet customer needs, and failure to maintain high acid value, etc. problems, to achieve the effects of environmental protection and safety, control of molecular weight range, and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Inhale 3,500 kg of molten rosin in a six-ton reactor, add 540 kg of maleic anhydride at 144°C, heat up, and perform addition reaction at a temperature of 200-210°C for 1 hour. After the addition reaction is finished, add 240 kg of pentaerythritol and 3 kg of zinc oxide, and stir at 220-225° C. to fully dissolve the solid material. Then heat up, and the adduct and pentaerythritol undergo esterification reaction at 255-260° C. for 5.5 hours. Sampling in the control laboratory, acid value 161.3mg KOH / g, softening point 148 ℃ (see Table 1), the product meets the enterprise quality standards. Cool down to 255°C, pass through the 60-100 mesh filter installed in the discharge tray, filter to remove impurities, put the filter into the reaction tray and cool it into a transparent solid, the color is No. 9, and the product maleic anhydride resin is obtained , the total yield was 95.1%.

Embodiment 2

[0025] Inhale 3,500 kg of molten rosin in a six-ton reactor, add 880 kg of maleic anhydride at 147°C, heat up, and perform addition reaction at a temperature of 205-212°C for 1.5 hours. After the addition reaction is finished, add 360 kg of pentaerythritol and 4.5 kg of zinc oxide, and stir at 220-228°C to fully dissolve the solid material. Then heat up, and the adduct and pentaerythritol undergo esterification reaction at 252-262° C. for 6 hours. Sampling for central control testing showed acid value 175.3mg KOH / g, softening point 135°C, continued esterification reaction at 252-262°C for 1 hour, and again central control test showed acid value 157mg KOH / g, softening point 152°C, the product In line with corporate quality standards. Cool down to 255°C, pass through the 60-100 mesh filter installed in the discharge tray, filter to remove impurities, put the filter into the reaction tray and cool it into a transparent solid, the color is No. 9, and the product maleic anhydrid...

Embodiment 3

[0027] Inhale 3,500 kg of molten rosin in a six-ton reactor, add 990 kg of maleic anhydride at 148°C, heat up, and perform addition reaction at a temperature of 210-218°C for 2 hours. After the addition reaction is over, add 480 kg of pentaerythritol and 5.5 kg of zinc oxide, and stir at 222-230° C. to fully dissolve the solid material. Then heat up, and the adduct and pentaerythritol undergo esterification reaction at 255-265° C. for 6.5 hours. Sampling in the control laboratory, the acid value is 167mg KOH / g, the softening point is 154°C, and the product meets the enterprise quality standards. Cool down to 255°C, pass through the 60-100 mesh filter installed in the discharge tray, filter to remove impurities, put the filter into the reaction tray and cool it into a transparent solid, the color is No. 9, and the product maleic anhydride resin is obtained , the total yield was 96.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com