Mounting structure of fabricated movable frame type separation wall

A technology for moving frame and installation structure, applied in the direction of walls, building components, building structures, etc., can solve the problem of non-movable partition walls, and achieve the effects of easy disassembly, reduced building load-bearing, and high compressive and heavy-duty strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

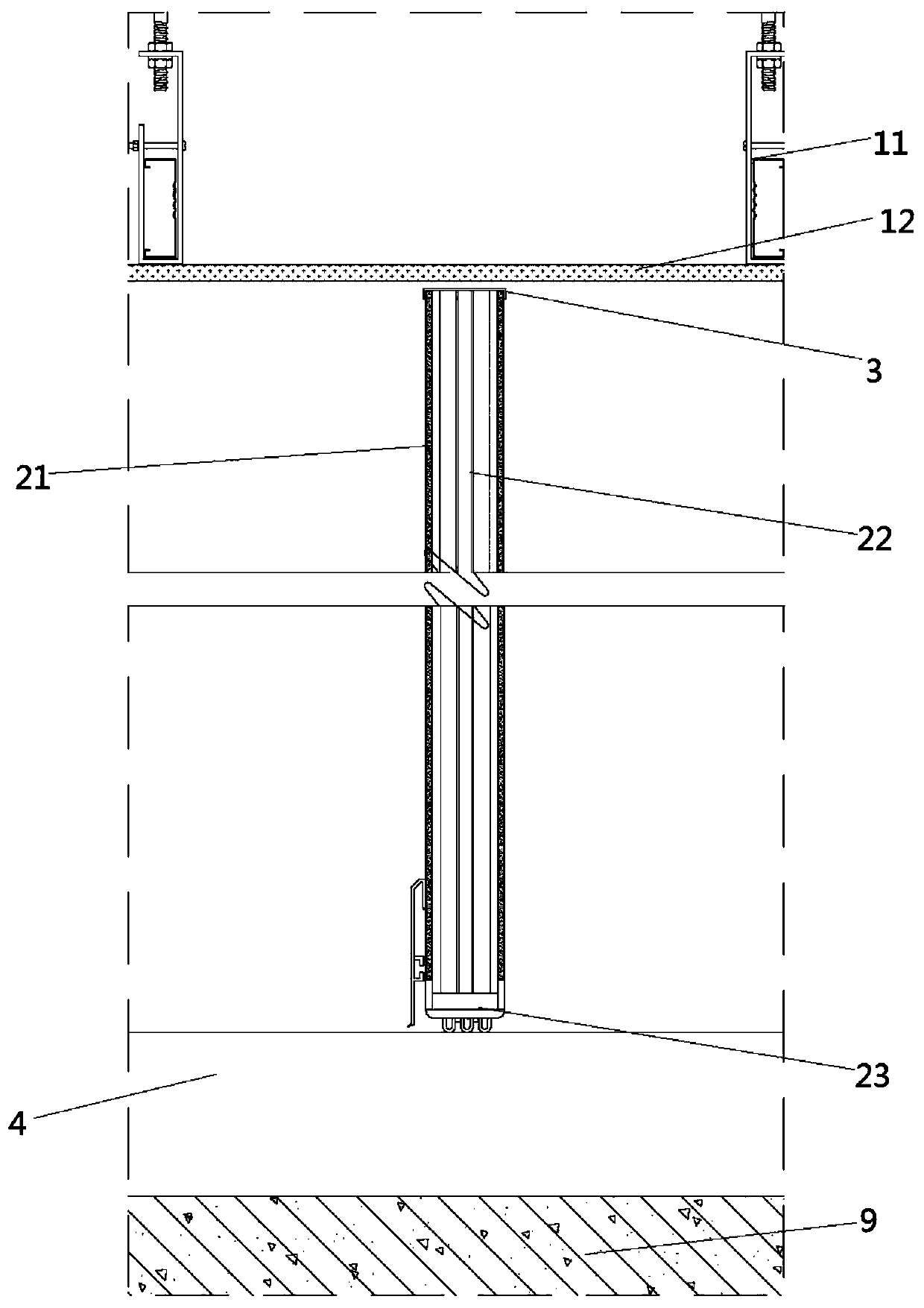

[0036] see Figure 1 to Figure 2 , Image 6 , the figure shows the installation structure of an assembled movable frame-type partition wall provided by Embodiment 1 of the present invention, the suspended ceiling, which includes a keel connector 11 connected to the top of the wall and a suspended ceiling layer 12, the keel connector 11 The bottom of the ceiling is connected with the suspended ceiling layer 12; the frame partition wall includes decorative wall panels 21 on both sides and a sound insulation laminate 22 arranged in the middle, the middle of the sound insulation laminate 22 is filled with sound insulation cotton, and the bottom of the frame partition wall is provided with Mobile wheel 23; top corner line 3, which is arranged between the suspended ceiling layer 12 and the frame partition wall, the side of the top corner line 3 is in the shape of “[”, the top of the frame partition wall is clamped in the top corner line 3, and the top corner line A non-contact stru...

Embodiment 2

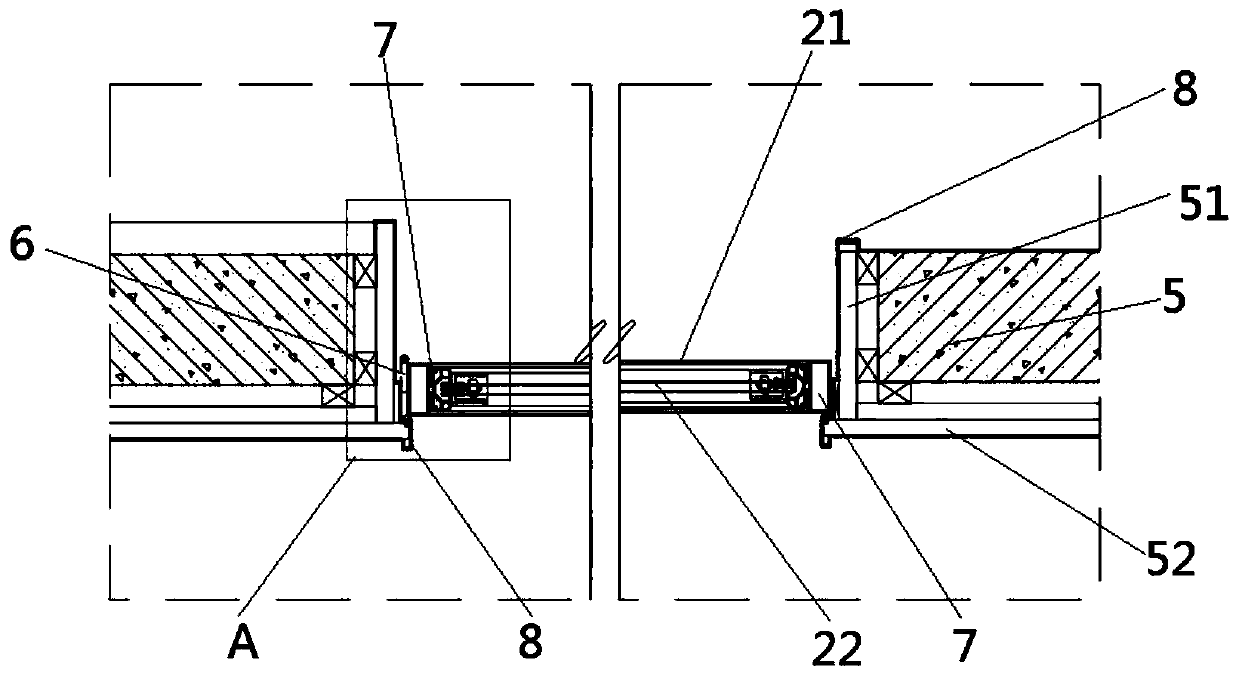

[0046] see Figure 1 to Figure 2 , Figure 5, the figure shows the installation structure of a prefabricated movable frame-type partition wall provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements One side of the frame partition wall is hinged to the side wall 5, and the two are connected by hinge 6 rotation; the outer side of the side wall 5 is provided with an outer frame 51, and one side of the outer frame 51 is provided with a limit plate 52; the limit plate 52 Anti-collision strips 53 are arranged on the inner side; connecting members 8 are also arranged on the edge of the outer frame 51 , and hook-shaped structures are arranged at both ends thereof. Through the setting of the above structure, the frame partition wall can be rotated along the side wall 5 through the hinge 6, and at the same time, there is an outer frame 51 between the two ends of ...

Embodiment 3

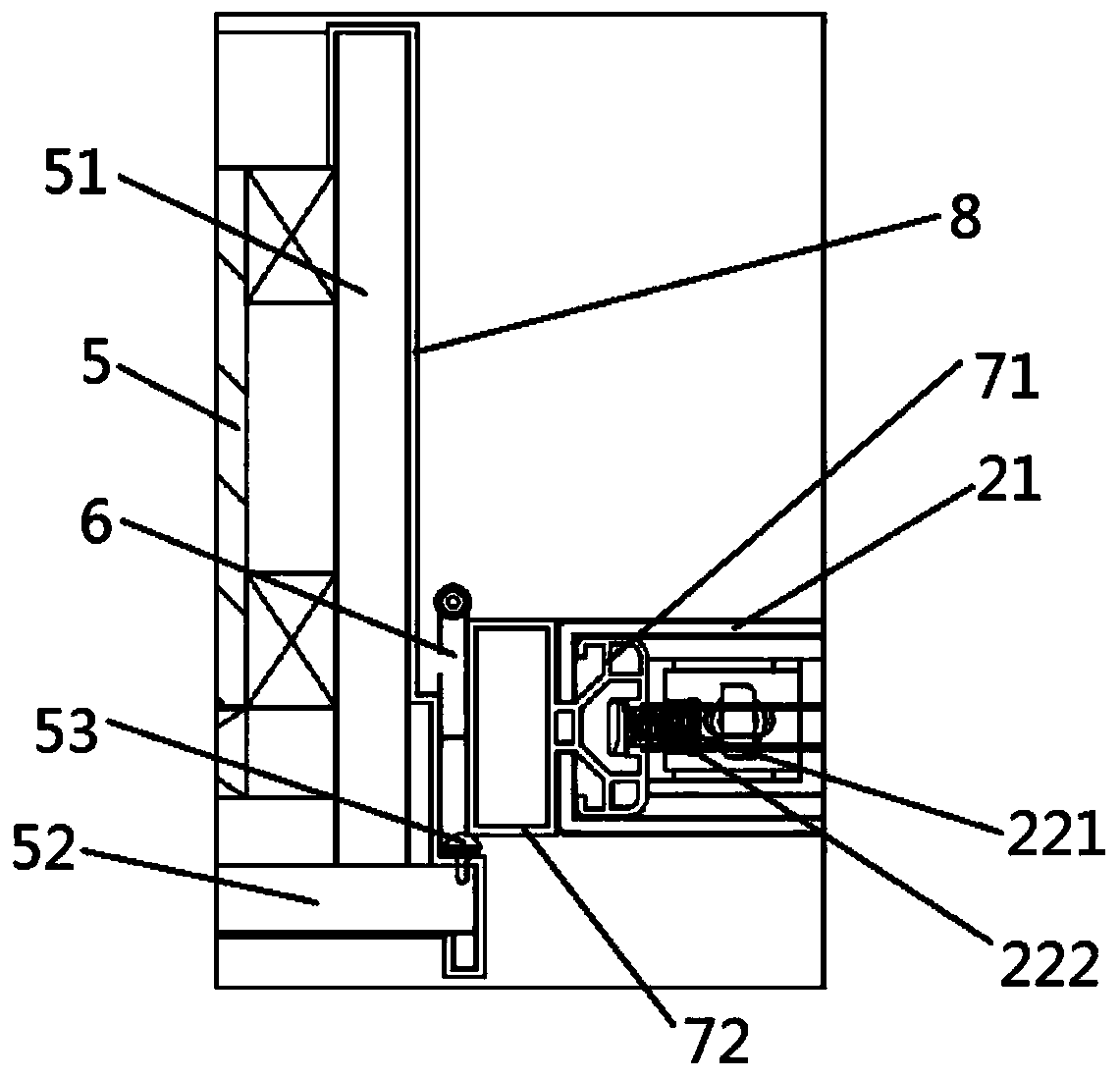

[0048] see Figure 1 to Figure 4 , the figure shows the installation structure of a prefabricated movable frame-type partition wall provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements : both sides of the decorative wallboard 21 are provided with a protective backing plate 7, the protective backing plate 7 is located between the side wall 5 and the decorative wallboard 21; the protective backing plate 7 includes a protective plate 71 and a connecting plate 72 arranged on the inner side of the protective plate 71 The connecting plate 72 is provided with a card slot 721 and a connecting slot 722, the card slot 721 is located on both sides of the connecting plate 72, and is located between the protective plate 71 and the connecting plate 72; the connecting slot 722 is located in the middle of the outer side of the connecting plate 72; The decorative wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com