Epoxy modified acrylic resin for sealant and preparing method thereof

An acrylic resin and epoxy modification technology, used in the field of sealants, can solve the problems of poor weather resistance, low shrinkage, hardness, pollution resistance, solvent resistance, mechanical properties and special substrate adhesion. The effect of good performance, excellent heat resistance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

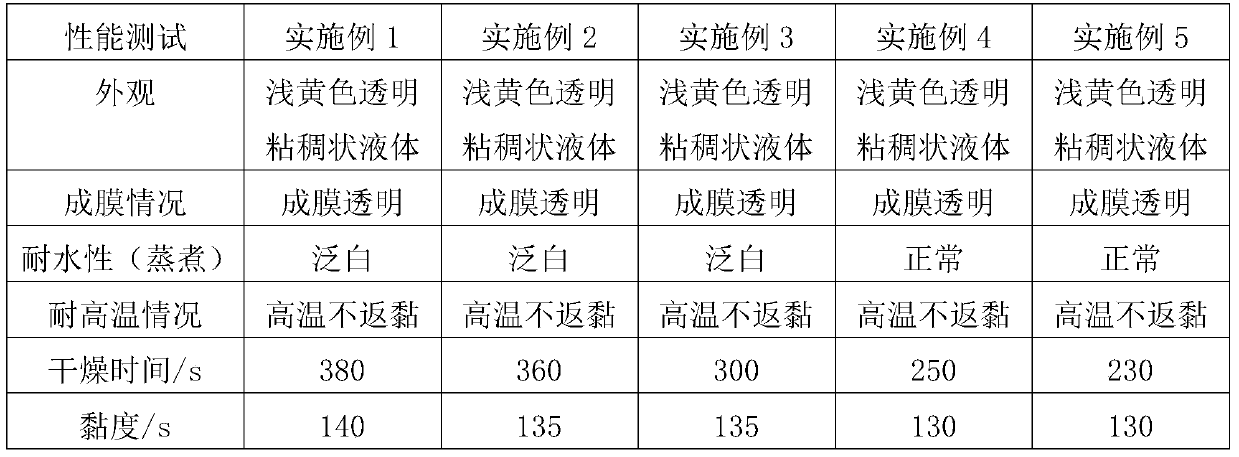

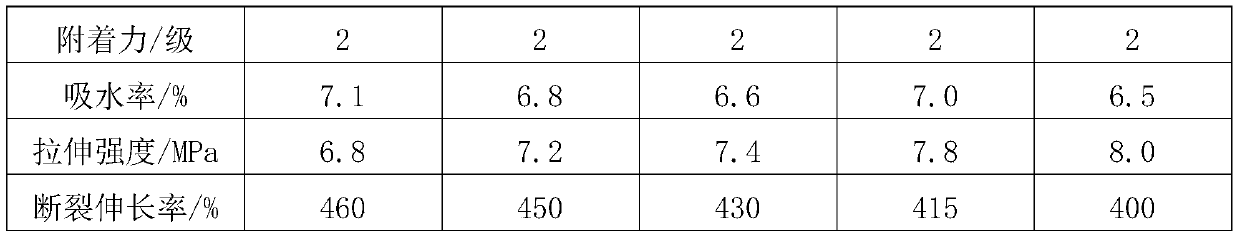

Examples

Embodiment 1

[0020] (1) Stir and mix 50Kg methyl methacrylate, 50Kg butyl acrylate, 1.5Kg benzoyl peroxide and 30Kg isopropanol, pump them into a storage tank, and set aside;

[0021] (2) Add 8Kg epoxy resin E-44, 20Kg isopropanol and 2Kg dodecanethiol into the reaction kettle, heat and stir until dissolved, add 1 / 3 of the mixed monomer prepared in step (1), and heat up to 85°C After 30 minutes of reaction, start to add the remaining 2 / 3 of the mixed monomer dropwise, and finish the drop after 2 hours. After the dropwise addition, continue the 85°C heat preservation reaction for 3h, then cool down to 40°C, add 10Kg of isopropanol to stir and dilute, and discharge. A uniform and stable epoxy-modified acrylic resin for sealants is prepared.

Embodiment 2

[0023] (1) Stir and mix 54Kg methyl methacrylate, 46Kg butyl acrylate, 1.6Kg potassium persulfate and 35Kg n-butanol, pump it into the storage tank, and set aside;

[0024] (2) Add 9Kg epoxy resin E-44, 15Kg n-butanol and 2.5Kg dodecanethiol in the reaction kettle, heat and stir until dissolved, add 1 / 3 step (1) prepared mixed monomer, heat up to 110 ℃, after reacting for 35 minutes, start to add the remaining 2 / 3 of the mixed monomer dropwise, and finish dropping in 2.5 hours. material, to obtain a uniform and stable epoxy-modified acrylic resin for sealants.

Embodiment 3

[0026] (1) Stir and mix 58Kg methyl methacrylate, 42Kg butyl acrylate, 1.8Kg benzoyl peroxide and 40Kg ethanol, pump it into a storage tank, and set aside;

[0027] (2) Add 11Kg epoxy resin E-44, 20Kg ethanol and 3.5Kg dodecanethiol into the reaction kettle, heat and stir until dissolved, add 1 / 3 of the mixed monomer prepared in step (1), and heat up to 78°C , after 30 minutes of reaction, start to add the remaining 2 / 3 of the mixed monomer dropwise, and finish the drop in 2 hours. After the dropwise addition, continue to heat the reaction at 78°C for 3h, then lower the temperature to 40°C, add 15Kg of ethanol to stir and dilute, and discharge to obtain Epoxy modified acrylic resin for uniform and stable sealant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com