Water-based after-tack-resistant anticorrosive primer as well as preparation method and application thereof

An anti-corrosion primer, water-based technology, applied in the direction of anti-corrosion coatings, coatings, epoxy resin coatings, etc., can solve the problems of poor anti-adhesive performance, long drying time, high cost, etc., and achieve excellent anti-adhesive performance, dry The effect of fast speed and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

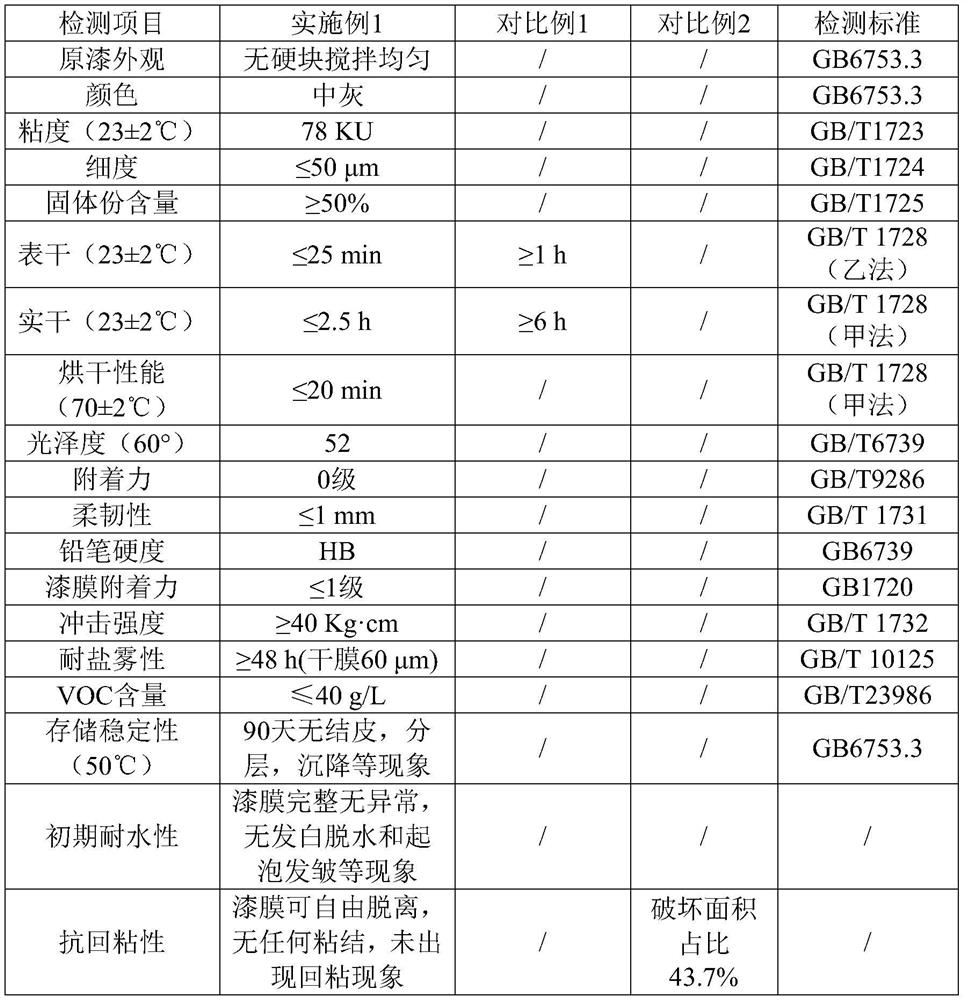

Examples

Embodiment 1

[0050] This embodiment provides a water-based anti-sticking anti-corrosion primer, and its raw materials and proportions are shown in Table 1.

[0051] In Table 1, the waterborne epoxy ester resin is Tianhe 8390 waterborne epoxy ester resin.

[0052] The pH regulator is dimethylethanolamine.

[0053] The drier is Tianhe water-based composite drier TH3305.

[0054] The wetting agent is acetylenic diol nonionic wetting agent, Guangzhou Fengshuo Chemical Technology Co., Ltd., brand V-104E.

[0055] The dispersant is water-based polyurethane dispersant, Guangdong Nanhui New Material Co., Ltd., brand N-1775.

[0056] The defoamer is a silicone defoamer, Zhoushan Tiande New Material Co., Ltd., brand DJ-296.

[0057] The acrylic emulsion is the S-98-4 acrylic emulsion of Foshan Shunde Badefu Industrial Co., Ltd., a translucent milky white liquid, with a solid content of 48±1%, a particle diameter of 0.1-0.2μm, and a minimum film-forming temperature of 25°C .

[0058] The anti-fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com