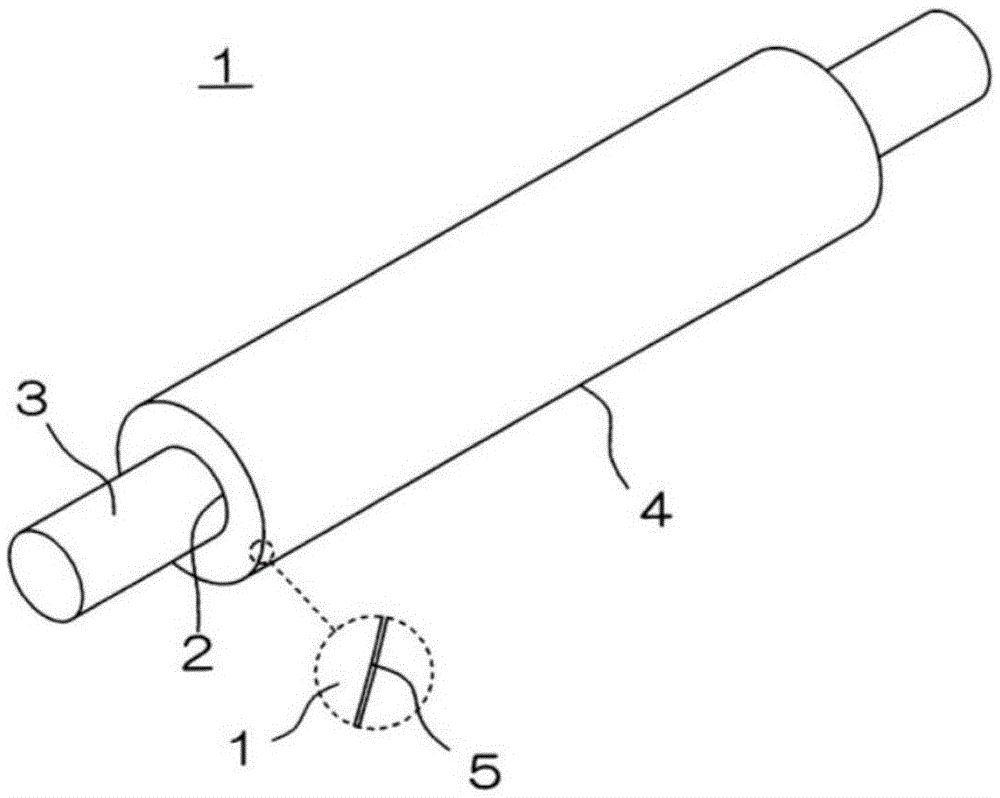

Semiconductive roller

A semi-conductive, rubber-based technology, which is applied in the direction of electrography, electrical recording technology using charge patterns, and equipment using electric recording technology using charge patterns, etc. It can solve problems such as bad images, unrecoverable images, uneven images, etc. , to achieve the effect of excellent image durability, not easy to deteriorate the toner, and not easy to stain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

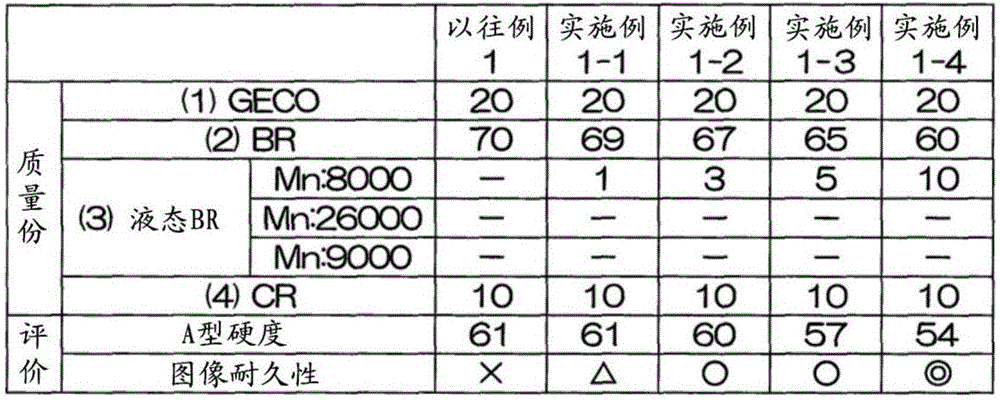

Embodiment 1-1

[0173] (Preparation of rubber composition)

[0174] Each of the following rubber components was blended.

[0175] (1) GECO [EPION (registered trademark)-301 manufactured by DAISO Co., Ltd., EO / EP / AGE=73 / 23 / 4 (molar ratio)] 20 parts by mass

[0176] (2) BR [the aforementioned JSR BR01 manufactured by JSR Corporation, cis-1,4 bond content: 95%] 69 parts by mass

[0177] (3) Liquid BR [Kurapuren LBR-307 manufactured by KURARAY Co., Ltd. mentioned above, number average molecular weight Mn: 8000] 1 part by mass

[0178] (4) 10 parts by mass of CR [the above Showa Denko Co., Ltd. SHOWPRENEWRT]

[0179] While masticating 100 parts by mass of the rubber components (1) to (4) above using a Banbury mixer, conductive carbon black (granular product of DENKABLACK (registered trademark) manufactured by Denki Kagaku Kogyo Co., Ltd.) was blended. 20 parts by mass and 5 parts by mass of Znhua [Mitsui Metal Mining Co., Ltd., two types of zinc oxide] as a crosslinking auxiliary agent were kne...

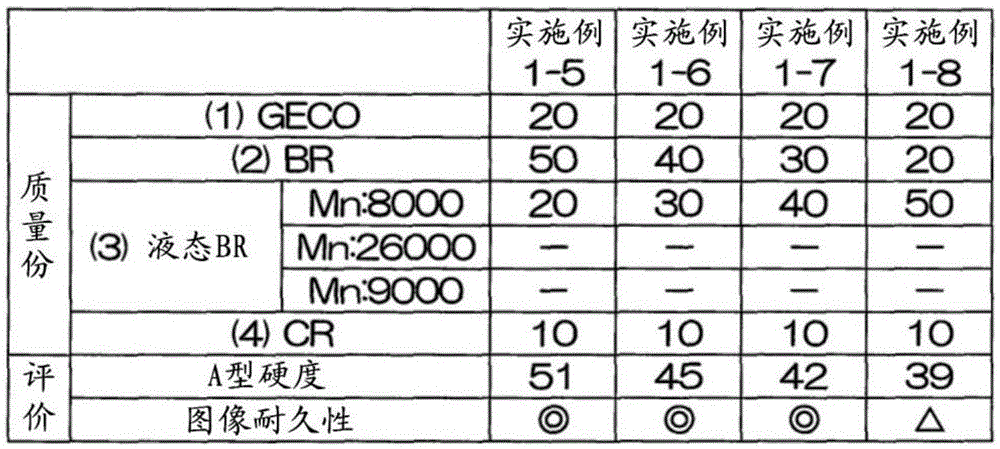

Embodiment 1-2~1-8

[0194] The amount of the liquid BR of (3) is 3 mass parts (embodiment 1-2), 5 mass parts (embodiment 1-3), 10 mass parts (embodiment 1-4), 20 mass parts (embodiment 1 -5), 30 parts by mass (Example 1-6), 40 parts by mass (Example 1-7) and 50 parts by mass (Example 1-8), and the total amount of the rubber component becomes 100 parts by mass Except for adjusting the amount of BR in (2), a rubber composition was prepared in the same manner as in Example 1-1, and a semiconductive roller was produced.

Embodiment 1-9~1-15

[0196] As the liquid BR of (3), the above-mentioned Kurapuren LBR-305 [number average molecular weight Mn: 26000] manufactured by KURARAY Co., Ltd. was used, and the amount was 1 part by mass (Example 1-9), 5 parts by mass (Example 1-9) Example 1-10), 10 parts by mass (Example 1-11), 20 parts by mass (Example 1-12), 30 parts by mass (Example 1-13), 40 parts by mass (Example 1-14) and 50 parts by mass (Example 1-15), and the amount of BR in (2) was adjusted respectively so that the total amount of the rubber component became 100 parts by mass, and a rubber combination was prepared in the same manner as in Example 1-1. material to make semi-conductive rollers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com