Cyclic and comprehensive utilization method of sodium-free mangano-manganic oxide production mother solution

A technology of trimanganese tetraoxide and mother liquor, applied in the direction of improving process efficiency, etc., can solve the problems of high production cost, difficult and efficient LiOH, simple and convenient recycling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

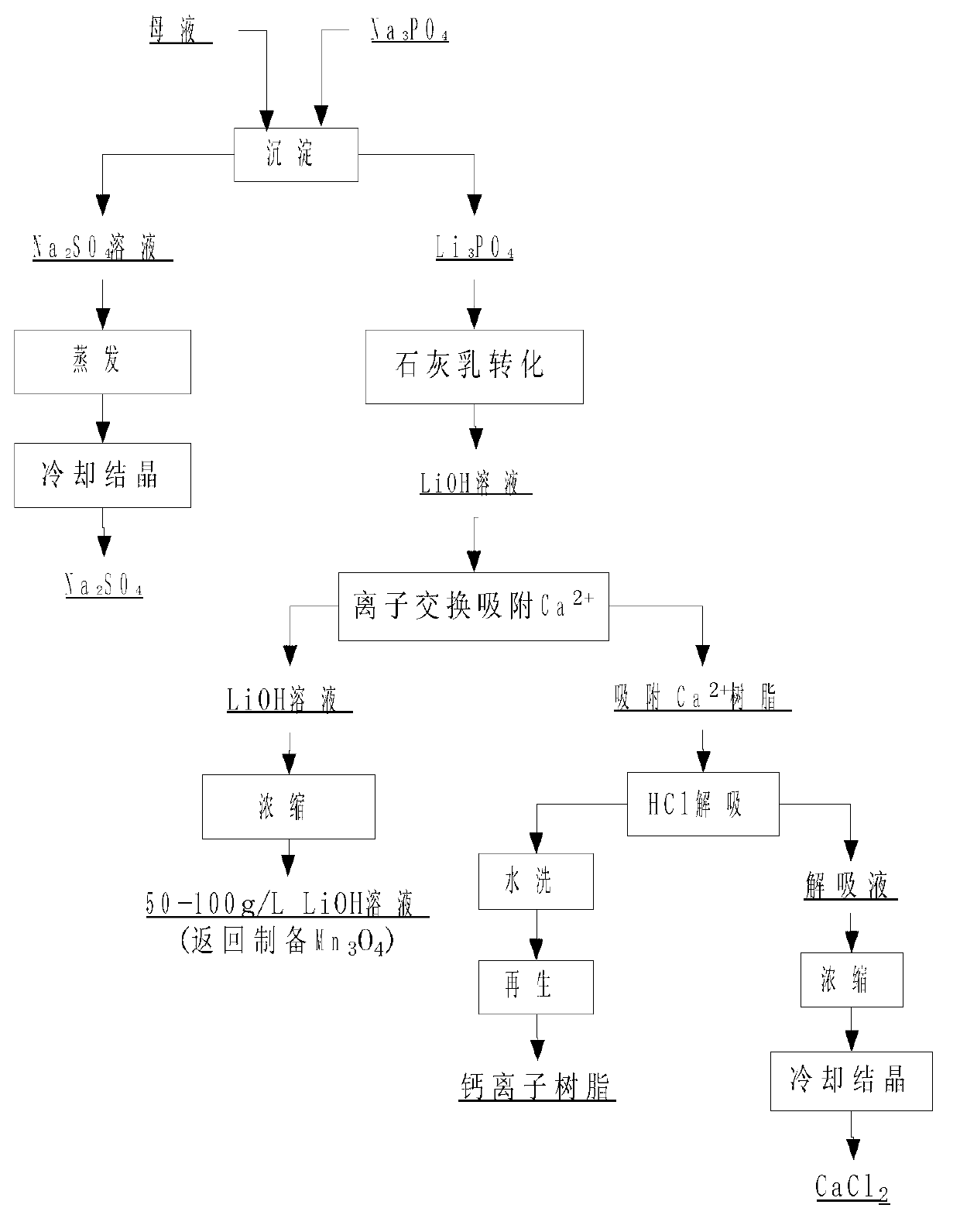

Method used

Image

Examples

Embodiment 1

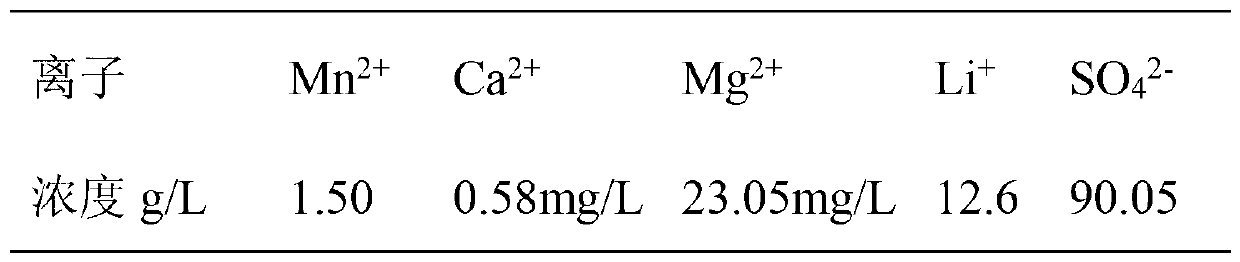

[0021] Sodium-free manganese tetraoxide production mother liquor mainly contains Mn 2+ , Ca 2+ , Mg 2+ , Na + , SO 4 2- Plasma, the specific composition is shown in Table 1.

[0022] 1. Measure 10L of trimanganese tetraoxide production mother liquor, prepare 2.78L of sodium phosphate solution with a concentration of 370g / L, slowly add sodium phosphate solution into trimanganese tetraoxide production mother liquor, stir while adding, and react at room temperature for 1h, Then filter to obtain sodium sulfate solution, lithium phosphate, and manganese phosphate precipitates, wash the precipitates twice with deionized water, dry, grind and pass through a 300-mesh sieve to obtain 728.9 grams of mixed powder of lithium phosphate and manganese phosphate. The sodium sulfate solution was concentrated, cooled and crystallized to obtain solid sodium sulfate.

[0023] 2. Slaked Lime Conversion Lithium Phosphate and Manganese Phosphate Mixed Powder

[0024] Weigh 330 grams of mixed...

Embodiment 2

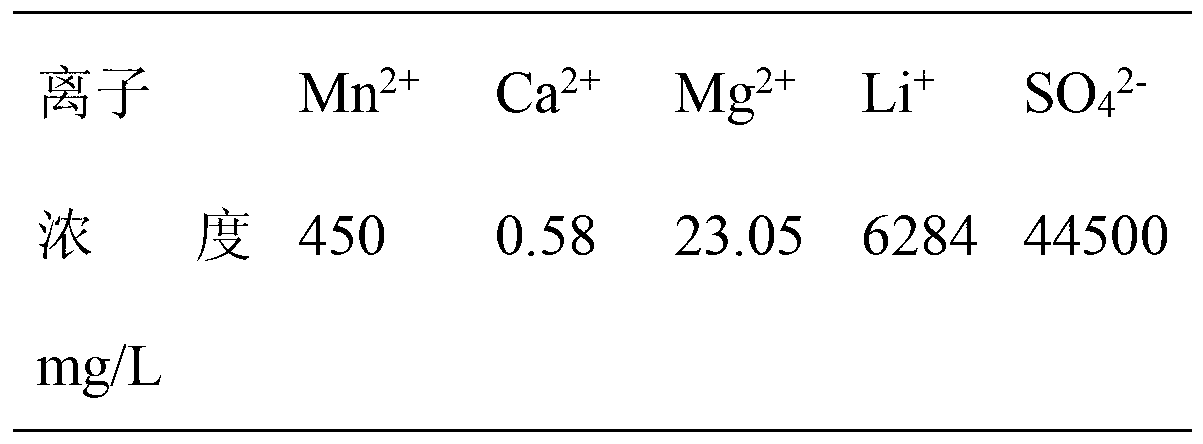

[0036] Sodium-free manganese tetraoxide production mother liquor mainly contains Mn 2+ , Ca 2+ , Mg 2+ , Na + , SO 4 2- Plasma, the specific composition is shown in Table 2.

[0037] 1. Measure 10L of sodium-free manganese tetraoxide production mother liquor, prepare 3.02L of sodium phosphate solution with a concentration of 185g / L, slowly add the sodium phosphate solution into the production mother liquor of trimanganese tetraoxide, stir while adding, at room temperature React for 1 h, then filter to obtain sodium sulfate solution, lithium phosphate, and manganese phosphate precipitates, wash the precipitates twice with deionized water, dry, grind and pass through a 300-mesh sieve to obtain 357 grams of mixed powder of lithium phosphate and manganese phosphate. The sodium sulfate solution was concentrated, cooled and crystallized to obtain solid sodium sulfate.

[0038] 2. Slaked Lime Conversion Lithium Phosphate and Manganese Phosphate Mixed Powder

[0039] Weigh 330...

Embodiment 3

[0051] Sodium-free manganese tetraoxide production mother liquor mainly contains Mn 2+ , Ca 2+ , Mg 2+ , Na + , SO 4 2- Plasma, the specific composition is shown in Table 3.

[0052] Measure 10L of trimanganese tetraoxide production mother liquor, prepare 1.74L of sodium phosphate solution with a concentration of 185g / L, slowly add sodium phosphate solution into trimanganese tetraoxide production mother liquor, stir while adding, react at room temperature for 1h, and then filter , to obtain sodium sulfate solution and lithium phosphate, manganese phosphate precipitate, the precipitate was washed twice with deionized water, dried, ground and passed through a 300 mesh sieve to obtain 193.6 grams of lithium phosphate and manganese phosphate mixed powder. The sodium sulfate solution was concentrated, cooled and crystallized to obtain solid sodium sulfate.

[0053] 2. Slaked Lime Conversion Lithium Phosphate and Manganese Phosphate Mixed Powder

[0054] Weigh 165 grams of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com