Boron-removed polysulphone modified affinitive membrane as well as preparation method and application

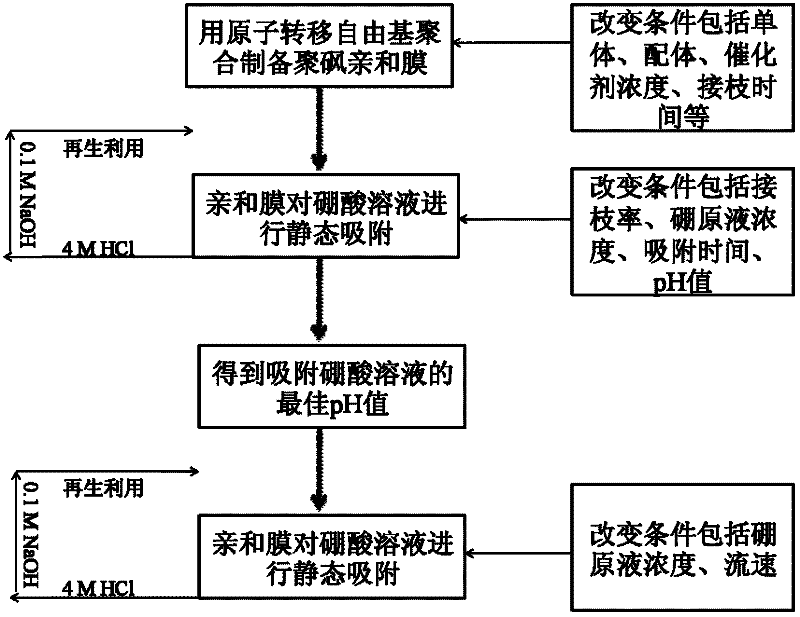

A technology of affinity membrane and chloromethylated polysulfone membrane, which is applied in the field of preparation of polysulfone affinity membrane and deboronation performance, can solve the problems of poor deboronation ability and small adsorption capacity, so as to achieve non-pollution, easy scale-up, The effect of small mass transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

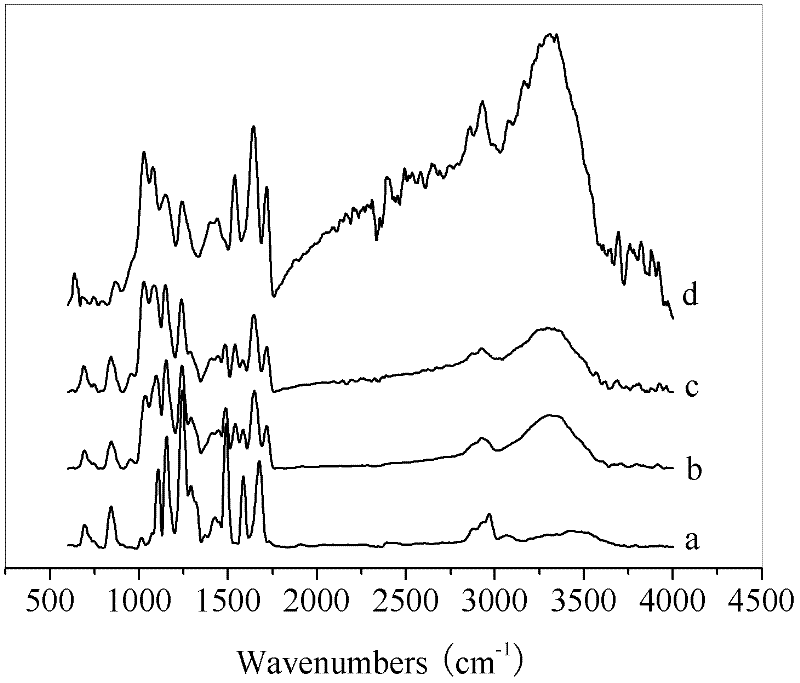

[0027] Preparation of chloromethylated polysulfone membrane:

[0028] (1) Dissolve the casting solution with ingredients of chloromethyl polysulfone (18wt%), polyvinylpyrrolidone (7wt%) and N-methylpyrrolidone (75wt%) at 60°C for 24h, and let stand for degassing for 24h ;

[0029] (2) using deionized water as a coagulation bath to make a chloromethylated polysulfone membrane by phase inversion at room temperature;

[0030] (3) Rinse the chloromethylated polysulfone membrane in an aqueous ethanol solution with a volume concentration of 70% in a water bath at 40°C, change the aqueous ethanol solution with a volume concentration of 70% every 1 hour, and rinse for 24 hours to obtain a clean Clean chloromethylated polysulfone membrane.

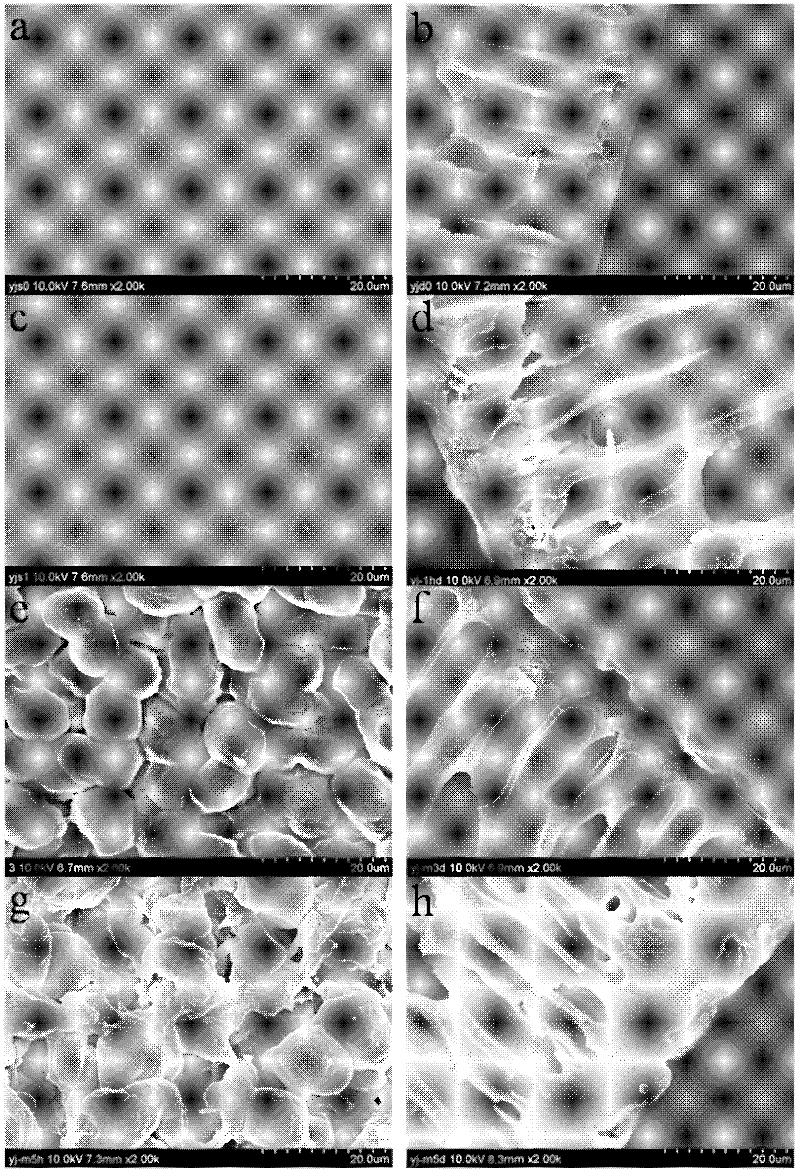

Embodiment 1

[0032] The preparation method of boron-removing polysulfone modified affinity membrane comprises the following steps:

[0033] (1) The cleaned area is 9cm 2 Chloromethylated polysulfone membrane with aqueous solution of atom transfer radical polymerization monomer -2-glucosamidoethyl methacrylate, copper chloride, atom transfer radical polymerization ligand N, N, N', N, Add 'N'-pentamethyldiethylenetriamine to the container, add deionized water to 50 ml, make the concentration of 2-glucosamidoethyl methacrylate 0.5 g / ml, and make copper chloride The concentration of N, N, N', N, 'N'-pentamethyldiethylenetriamine is 1.3 micromol / ml, so that the concentration of N, N, N', 'N'-pentamethyldiethylenetriamine is 13 mmol / ml;

[0034] (2) After filling the container with nitrogen for 10 minutes to remove the oxygen in the container, add 0.13 mmoles of cuprous chloride, continue to fill with nitrogen for 10 minutes, seal it, react at 30°C for 8 hours, take out the film, and put it in ...

Embodiment 2

[0039] The preparation method of boron-removing polysulfone modified affinity membrane comprises the following steps:

[0040] (1) The cleaned area is 9cm 2 The chloromethylated polysulfone membrane was added with an aqueous solution of 2-glucosamidoethyl methacrylate, copper chloride, N,N,N',N,'N'-pentamethyldiethylenetriamine To the container, add deionized water to 50 ml, make the concentration of 2-glucosamidoethyl methacrylate be 1 g / ml, make the concentration of copper chloride be 0.5 micromol / ml, make N, N, The concentration of N', N, 'N'-pentamethyldiethylenetriamine is 6.5 mmol / ml;

[0041] (2) After filling the container with nitrogen for 10 minutes to remove the oxygen in the container, add 0.26 mmoles of cuprous chloride, continue filling with nitrogen for 10 minutes, seal it, react at 30°C for 1 hour, take out the film, and put it in a water bath at 40°C without Wash with water and ethanol for 24 hours, wash with deionized water for 28 hours, take it out and dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com