Method for hydrophilic modification on surface of polyurethane carrier

A carrier surface, hydrophilic modification technology, applied in the direction of coating, can solve the problems of unstable surface properties and attenuation of materials, and achieve the effect of easy industrial production, strong flexibility and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

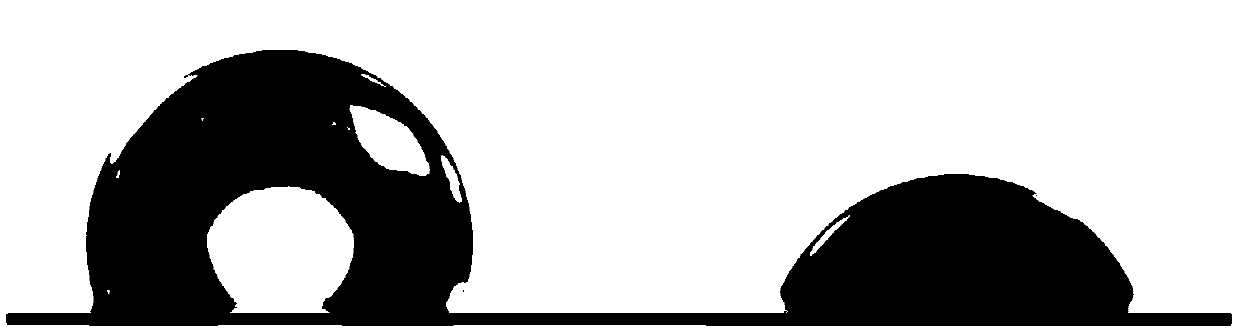

Image

Examples

Embodiment 1

[0028] (1) Soak the polyurethane film with absolute ethanol, then rinse repeatedly with deionized water, and place it in a vacuum drying oven to dry;

[0029] (2) Place the dried polyurethane carrier in a plasma treatment device, evacuate the instrument to a vacuum of 10 Pa, inject argon plasma gas, and adjust the pressure in the reactor to 50 Pa. After stabilization, start the high-frequency power supply, the processing power is 100W, and the processing time is 20min;

[0030] (3) Put the surface-treated polyurethane film into a polydiallyldimethylammonium chloride solution with a concentration of 0.01mmol / L, and soak for 15min at an adsorption temperature of 3°C. Take out the polyurethane film, clean it with deionized water, and then dry it with cold air at 1°C;

[0031] (4) Put the polyurethane film into a 0.05 mmol / L sodium polystyrene sulfonate solution at an adsorption temperature of 4° C. and soak for 20 min. Take out the polyurethane film, clean it with deionized wat...

Embodiment 2

[0035] (1) Soak the polyurethane film with absolute ethanol, then rinse repeatedly with deionized water, and place it in a vacuum drying oven to dry;

[0036] (2) Place the dried polyurethane carrier in a plasma treatment device, evacuate the instrument to a vacuum of 5 Pa, and inject argon plasma gas to adjust the pressure in the reactor to 70 Pa. After stabilization, start the high-frequency power supply, the processing power is 200W, and the processing time is 25min;

[0037] (3) Put the surface-treated polyurethane film into a cationic polyacrylamide solution with a concentration of 0.05mmol / L, and soak for 60min at an adsorption temperature of 2°C. Take out the polyurethane film, clean it with deionized water, and then dry it with cold air at 4°C;

[0038] (4) Put the polyurethane film into a 0.1 mmol / L sodium polystyrene sulfonate solution at an adsorption temperature of 2° C. and soak for 60 min. Take out the polyurethane film, clean it with deionized water, and then ...

Embodiment 3

[0042] (1) Soak the polyurethane film with absolute ethanol, then rinse repeatedly with deionized water, and place it in a vacuum drying oven to dry;

[0043] (2) Place the dried polyurethane carrier in a plasma treatment device, evacuate the instrument to a vacuum of 8 Pa, and inject argon plasma gas to adjust the pressure in the reactor to 20 Pa. After stabilization, start the high-frequency power supply, the processing power is 50W, and the processing time is 10min;

[0044] (3) Put the surface-treated polyurethane film into a chitosan solution with a concentration of 0.05mmol / L, and soak for 30min at an adsorption temperature of 6°C. Take out the polyurethane film, clean it with deionized water, and then dry it with cold air at 3°C;

[0045] (4) Put the polyurethane film into 0.01 mmol / L sodium polystyrene sulfonate solution at an adsorption temperature of 5° C. and soak for 15 min. Take out the polyurethane film, clean it with deionized water, and then dry it with cold ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com