Preparation and application of whisker-shaped ceramic membrane with low cost and high permeability

A high-permeability, ceramic membrane technology, used in semi-permeable membrane separation, membrane technology, chemical instruments and methods, etc., can solve problems such as high cost, nano-layer shedding, insufficient permeability, etc. The effect of hydrophilicity and high separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

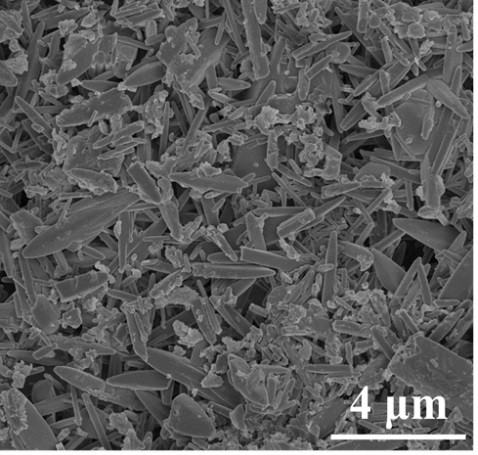

[0041] Embodiment 1: Preparation of whisker-like mullite ceramic film

[0042] (1) Handling of raw materials

[0043] The raw material powder of natural mineral bauxite and industrial waste fly ash is ball milled for 24-48 h, the particle size of the treated bauxite is mainly distributed in the range of 1.23-4.56 μm, and the average particle size (D50) is 2.9 μm; The particle size of fly ash is mainly distributed in the range of 0.69-5.20 μm, and the average particle size (D50) is 2.1 μm. The added tungsten oxide powder is used as a catalyst, dissolved in N-methylpyrrolidone (NMP) solvent as a polymer binder, and polyvinylpyrrolidone (PVP) is added as a dispersant to play the role of a uniform slurry.

[0044] (2) Preparation of casting solution

[0045] Weigh an appropriate amount of polyethersulfone (PES) and additive polyvinylpyrrolidone (PVP) and dissolve it in N-methylpyrrolidone (NMP) so that PES:NMP:PVP=8:32:1, and put it into the In the vinyl fluoride ball mill tank...

Embodiment 2

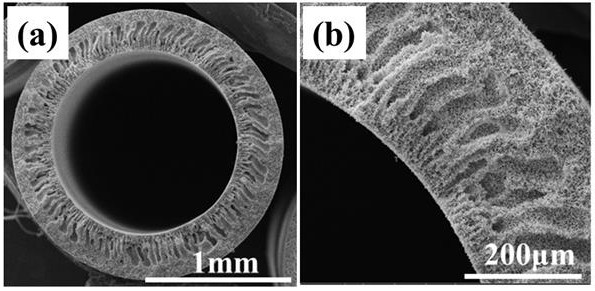

[0058] Example 2: Preparation of whisker-shaped ceramic membranes with low cost and high permeation flux by extrusion molding-high temperature sintering

[0059] The raw material powder of natural mineral bauxite and industrial waste fly ash is ball milled for 24-48 h, the particle size of the treated bauxite is mainly distributed in the range of 1.23-4.56 μm, and the average particle size (D50) is 2.9 μm; The particle size of fly ash is mainly distributed in the range of 0.69-5.20 μm, and the average particle size (D50) is 2.1 μm. Then the mixture of bauxite, fly ash and tungsten oxide powder (80 wt.%, of which tungsten oxide accounted for 20 wt.% of the powder), corn starch (10 wt.%), carboxymethyl cellulose (10wt. %) and other powders were fully and uniformly mixed and ball milled continuously for 10 h, and water was added according to the volume ratio of powder to water of 1.5:1 and then ball milled for 15 h to obtain a uniformly dispersed slurry. Then put the prepared sl...

Embodiment 3

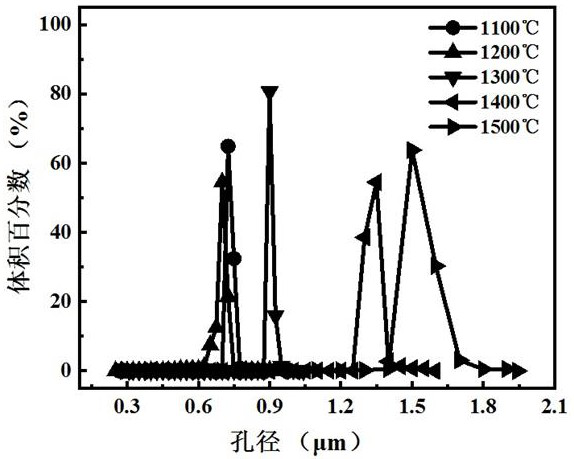

[0060] Example 3: Application of Whisker Mullite Ceramic Membrane in Treatment of High Concentration Oil-Water Emulsion

[0061] At different feed oil concentrations (250mg·L -1 , 500 mg·L -1 and 1000 mg·L -1 ) under the conditions of oil-water emulsion separation experiments, and the rest of the operating conditions are moderate. The results show that when the transmembrane pressure difference is 0.15 bar, the oil concentration of the whisker-shaped ceramic membrane obtained by sintering at 1100°C in Example 1 is 250-1000mg L -1 The oil-water emulsion has a good treatment effect, its oil retention rate is high (95-99%), the permeation flux is stable, and the regeneration ability is strong. In the first 10 minutes of filtration, oil droplets quickly accumulated on the surface of the membrane, resulting in the formation of a fouling layer and a decrease in flux. As the run time increases, the flux decreases very slowly due to the increased dynamic stability of the fouling l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com