A 3D printing method based on self-propagating reaction

A 3D printing, self-propagating technology, applied in the direction of additive processing, etc., can solve the problems of not being able to quickly obtain printed parts and poor mass production capacity, and achieve the effects of shortening the printing cycle, low cost, and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

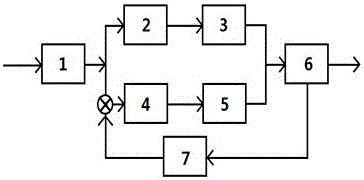

[0029] Such as figure 1 Shown a kind of 3D printing method based on self-propagating reaction of the present invention, comprises the following steps:

[0030] Step 1: Install the copper flange that needs to be repaired and perform size measurement and material analysis on the flange mouth. The material of the copper flange mouth is copper aluminum alloy, with an outer diameter of 200mm, an inner diameter of 100mm, a height of 30mm, and a wall thickness of 15mm;

[0031] Step 2: Use ProE to model the copper flange that needs to be repaired, and enter the measured data;

[0032] Step 3: Divide the built three-dimensional model into two-dimensional sections, each section height is 5mm, and transmit the section information to the displacement controller and the response controller through the software interface;

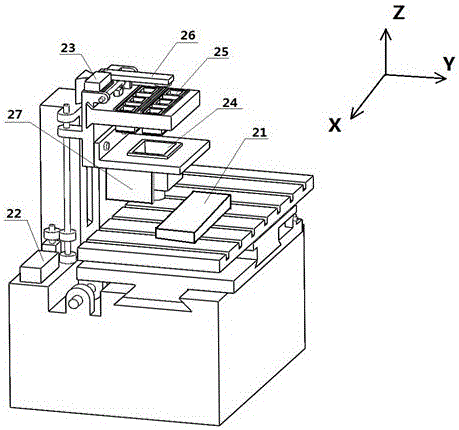

[0033] Step 4: The displacement controller retrieves the two-dimensional section information of the first layer, controls the combination of the X-axis motor and the ...

Embodiment 2

[0039] Such as figure 1Shown a kind of 3D printing method based on self-propagating reaction of the present invention comprises the following steps:

[0040] Step 1: Carry out size measurement and material analysis on the aluminum ingot mold to be printed, and the aluminum ingot mold material is cast iron, with a length of 980mm, a width of 285mm, a height of 180mm, and a wall thickness of 15mm;

[0041] Step 2: Use CATIA computer 3D modeling software to model the aluminum ingot mold to be printed, and input the measured data;

[0042] Step 3: Divide the built 3D model into 2D sections, and transmit the section information to the displacement controller and response controller through the software interface;

[0043] Step 4: The displacement controller retrieves the two-dimensional section information of the first layer, controls the combination of the X-axis motor and the Y-axis motor to move in a straight line, and travels 116mm and 100mm respectively, and the Z-axis motor ...

Embodiment 3

[0049] Such as figure 1 Shown a kind of 3D printing method based on self-propagating reaction of the present invention comprises the following steps:

[0050] Step 1: Install the aluminum tube to be repaired and conduct size measurement and material analysis on the nozzle. The material of the aluminum tube nozzle is aluminum alloy, with a diameter of 130mm and a wall thickness of 15mm;

[0051] Step 2: Use ProE to model the aluminum pipe that needs to be repaired, and enter the measured data;

[0052] Step 3: Divide the built three-dimensional model into two-dimensional sections, each section height is 10mm, and transmit the section information to the displacement controller and the response controller through the software interface;

[0053] Step 4: The displacement controller retrieves the two-dimensional section information of the first layer, and controls the combination of the X-axis motor and the Y-axis motor to make a semi-circular motion with a radius of 65mm. The low...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com