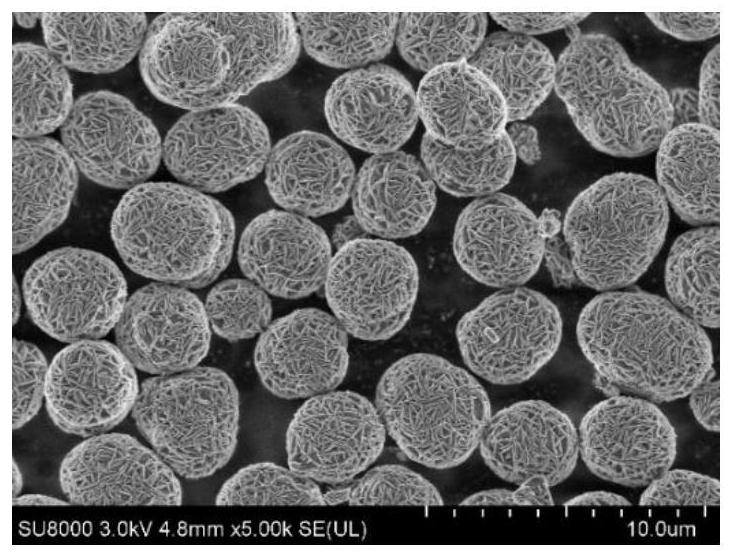

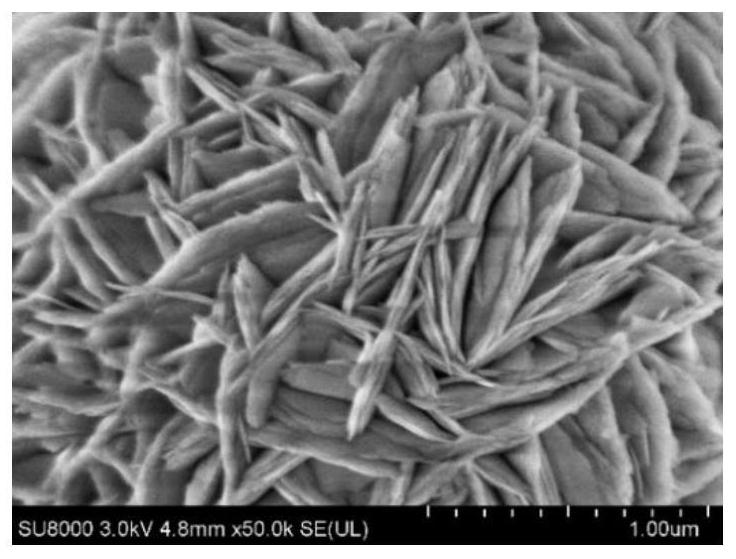

Spherical high-nickel cobalt-free single crystal precursor and preparation method thereof

A precursor, high-nickel technology, applied in chemical instruments and methods, inorganic chemistry, nickel compounds, etc., can solve the problems of high-nickel-cobalt-free precursors with high crystallinity, unfavorable sintering single crystallization, small specific surface, etc. The effect of improving the rate and cycle performance, reducing the single crystallization, and improving the ratio table

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step 1. Raw material solution preparation: Nickel sulfate and manganese sulfate are prepared into a 2mol / L solution according to the molar ratio of 0.90:0.08, and a sodium metaaluminate solution of 0.1mol / L is prepared as a doping solution, and sodium hydroxide is dissolved to a concentration of 10mol / L lye; use 13mol / L ammonia solution as complexing agent.

[0031] Step 2. Preparation of reaction bottom liquid: Add the prepared lye and ammonia solution into a reaction kettle filled with nitrogen and half a kettle of water. The reaction kettle adopts paddles with paddle diameter / kettle diameter = 0.60 to adjust the pH of the bottom liquid The value is 13.0, the ammonia concentration in the reaction bottom solution is controlled to be 10g / L, the stirring speed is controlled at 500rpm, and the temperature is controlled at 40°C.

[0032] Step 3, the reaction starts, the nickel-manganese mixed salt, aluminum salt, lye and ammonia solution are added to the reaction kettle eq...

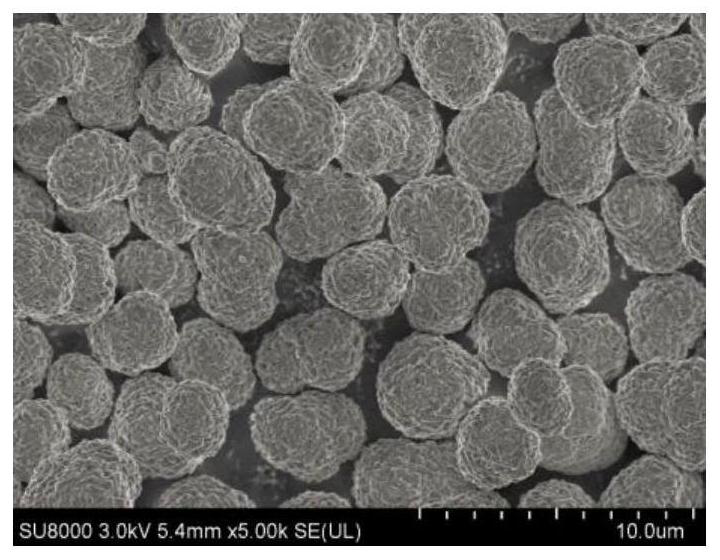

Embodiment 2

[0037] Step 1. Raw material solution preparation: nickel sulfate and manganese sulfate are prepared into a 2mol / L solution according to the molar ratio of 0.60:0.35, and a magnesium sulfate solution of 0.1mol / L is prepared as a doping solution, and sodium hydroxide is dissolved to a concentration of 10mol / L lye; use 13mol / L ammonia solution as complexing agent.

[0038] Step 2, preparation of the reaction bottom liquid: add the prepared lye and ammonia solution into the reactor filled with half a kettle of water with nitrogen, and the reactor adopts paddles with paddle diameter / kettle diameter = 0.65 to adjust the pH of the bottom liquid The value is 12.5, the ammonia concentration is 4g / L, the stirring speed is controlled at 300rpm, and the temperature is controlled at 20°C.

[0039] Step 3, the reaction starts, the nickel-manganese mixed salt, magnesium salt, lye and ammonia solution are added to the reaction kettle equipped with the reaction bottom liquid at the same time,...

Embodiment 3

[0044] Step 1. Raw material solution preparation. Nickel nitrate and manganese nitrate are prepared into a 2mol / L solution according to the molar ratio of 0.80:0.17, and a zirconium nitrate solution of 0.1mol / L is prepared as a doping solution, and sodium hydroxide is dissolved to a concentration of 10mol / L. L of lye; use 13mol / L of ammonia solution as complexing agent.

[0045] Step 2. Preparation of reaction bottom liquid: Add the prepared lye and ammonia solution into a reactor filled with nitrogen and half a pot of water. The reactor adopts paddle diameter / kettle diameter=0.55 to adjust the pH of the bottom liquid The value is 12.5, the ammonia concentration is 6g / L, the stirring speed is controlled at 400rpm, and the temperature is controlled at 30°C.

[0046] Step 3, the reaction starts, the nickel-manganese mixed salt, zirconium salt, lye and ammonia solution are added to the reaction kettle equipped with the reaction bottom liquid at the same time, the ammonia concentr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com