Engine oil dip stick and oil pan

A technology of engine oil and oil dipstick, applied in the direction of oil pan, engine components, machine/engine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

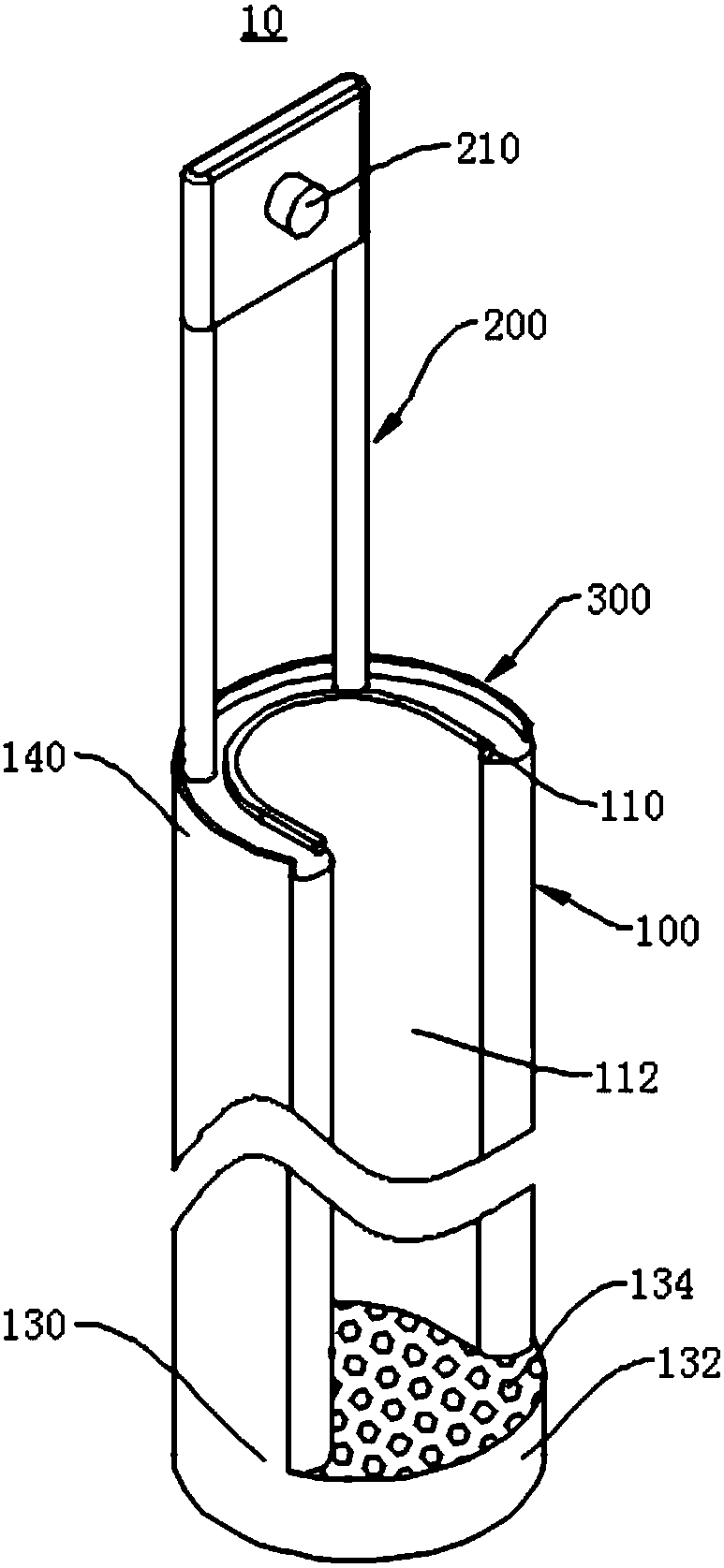

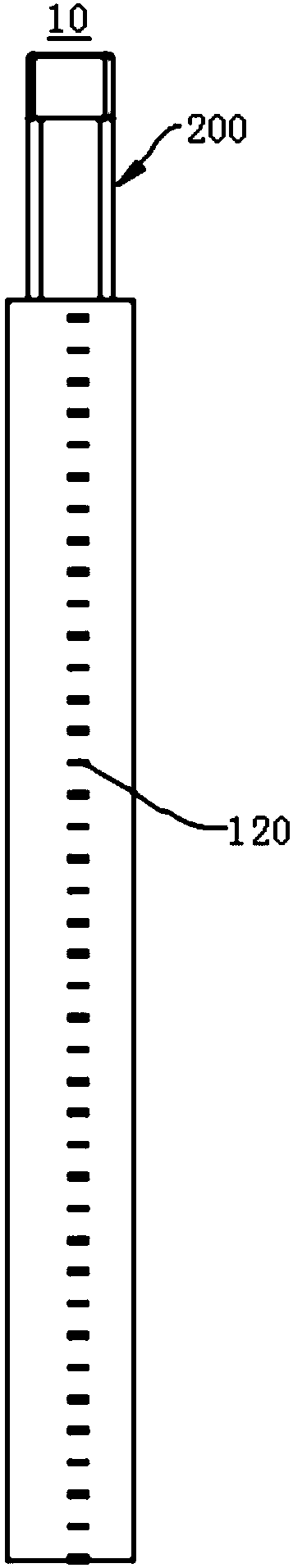

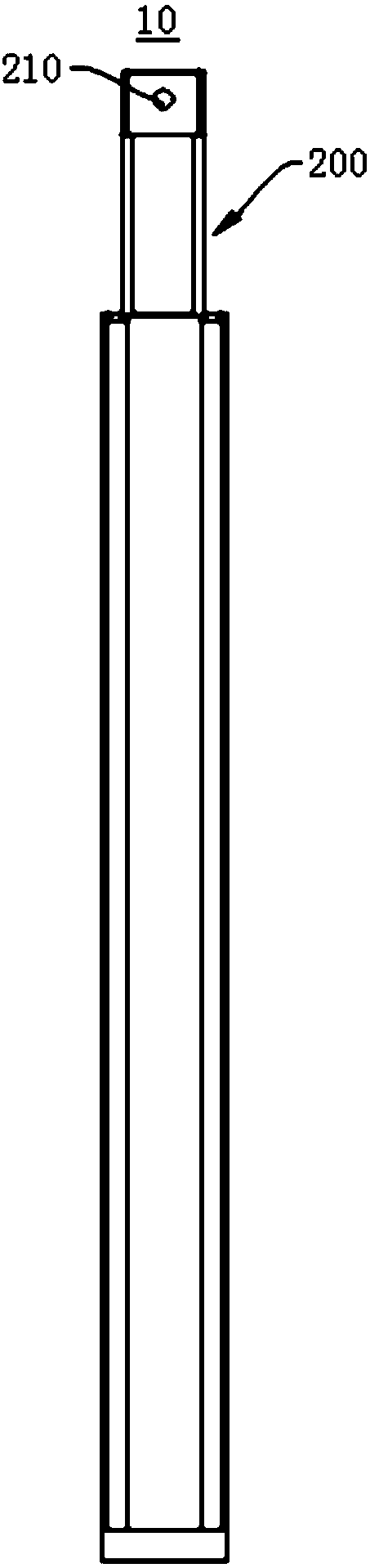

[0041] Please refer to Figure 1 to Figure 4 , the present embodiment provides an engine oil dipstick 10, which includes a ruler body 100; the ruler body 100 is provided with a groove, and the inner wall of the groove is provided with a magnetic part 110 for magnetically sucking the iron inside the oil; the magnetic part 110 is provided with a useful In the accommodating space 112 for accommodating iron cutting; along the length direction of the ruler body 100 is also provided with a scale line 120 .

[0042]The engine oil dipstick 10 provided in the embodiment of the present invention includes a ruler body 100; the ruler body 100 is provided with a groove, and the inner wall of the groove is provided with a magnetic part 110 for iron cutting in the magnetic suction machine oil; the magnetic part 110 is provided with There is an accommodating space 112 for accommodating iron cutting; a scale line 120 is also provided along the length direction of the ruler body 100, a groove i...

Embodiment 2

[0059] An oil pan is also provided in this embodiment, and the oil pan includes the above-mentioned engine oil dipstick 10 and the oil pan body; The engine oil dipstick 10 is used to extend into or out of the accommodating cavity.

[0060] The oil pan provided in the embodiment of the present invention includes the above-mentioned engine oil dipstick 10, so it can also avoid the problem that the outer wall of the ruler body 100 is difficult to protrude out of the oil pan due to the increase of the outer diameter of the outer wall of the ruler body 100 due to magnetic iron filings. The oil dipstick hole prevents the iron filings adsorbed on the outer peripheral wall of the ruler body 100 from being scraped off when it stretches out from the oil dipstick hole of the oil pan, and falls back into the engine oil again, causing problems such as clogging the filter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com