Method for reducing phosphorus by chloridization separation-weak of high phosphor iron ore

A high-phosphorus iron ore and weak magnetic separation technology, which is applied in the field of iron ore beneficiation and mineral processing, can solve the problems of fine and complex embedded particle size of phosphorus minerals, and the ineffective utilization of iron ore resources by phosphorus reduction methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

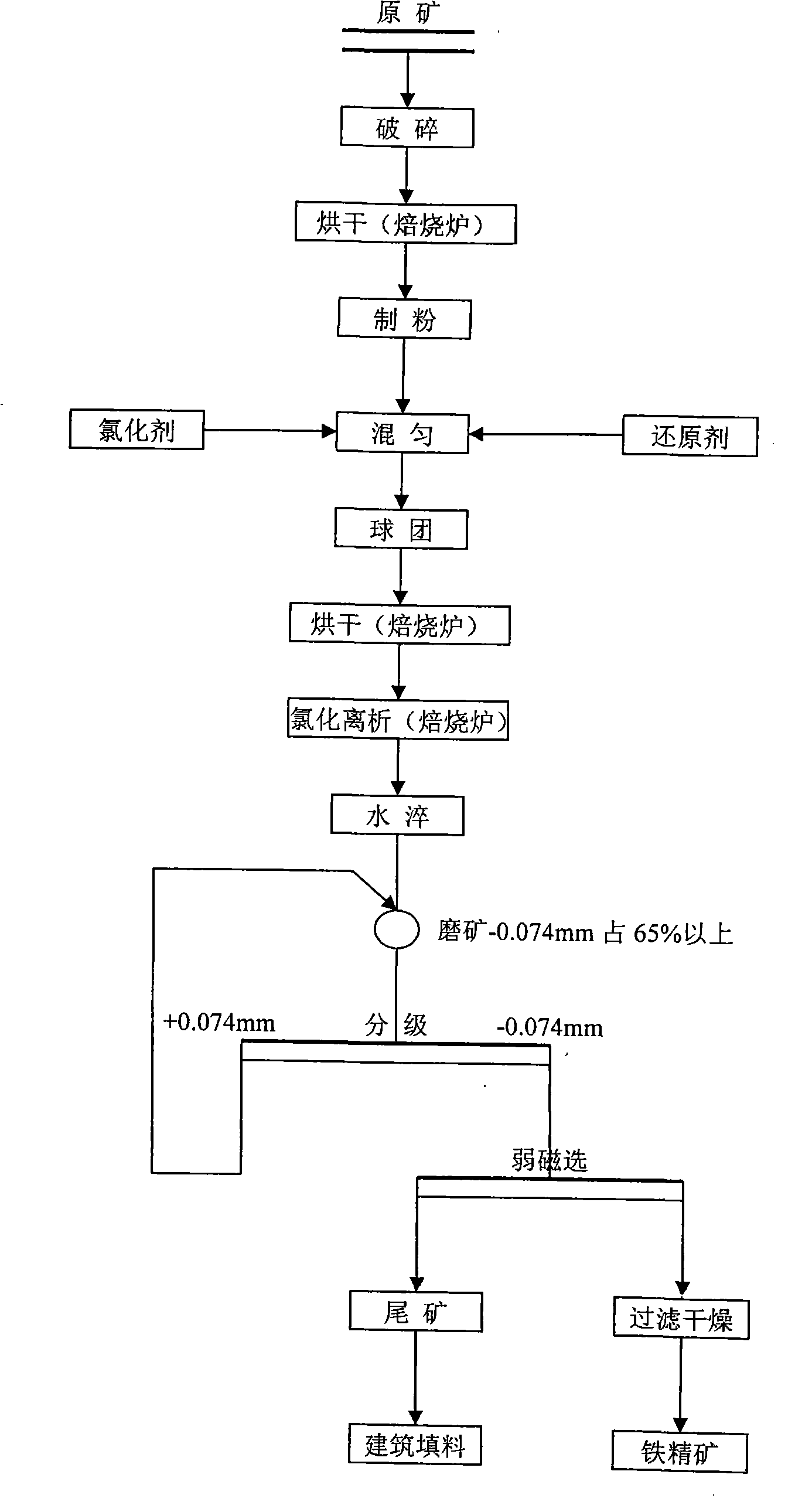

Method used

Image

Examples

Embodiment 1

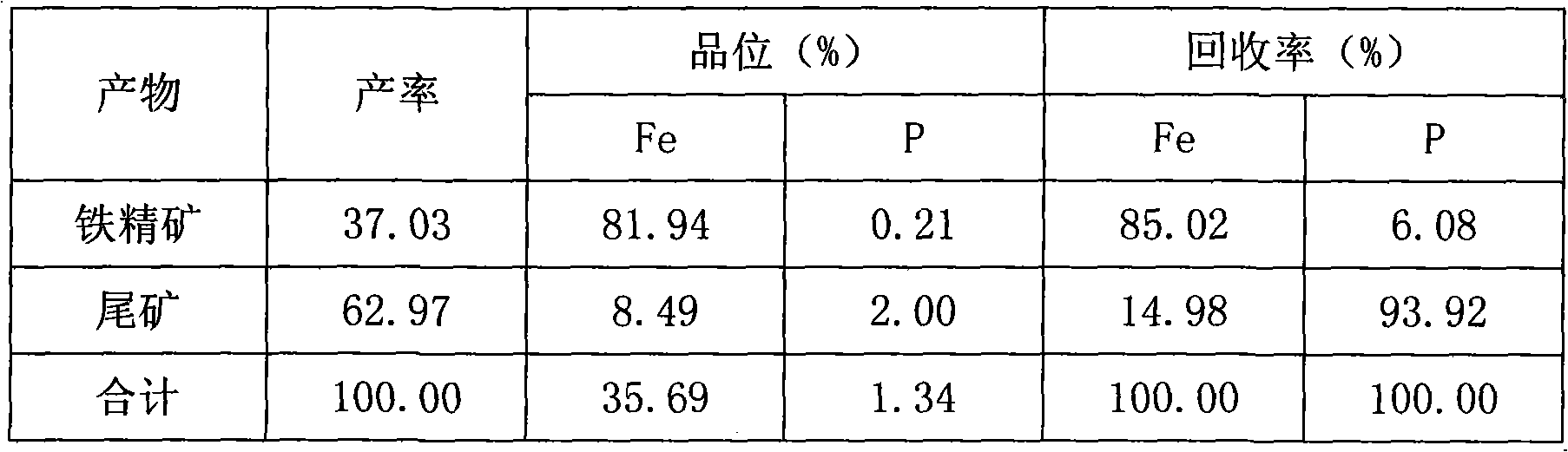

[0017] Example 1: The raw material comes from a certain area in Sichuan that contains 33-42wt% iron and about 1.30wt% phosphorus. The raw material contains limonite, hematite, and iron minerals such as pyrite, iron carbonate and iron silicate. The ore is crushed to below -5mm, dried in a roaster at 800℃, drying time 40min, ground to a particle size of less than 0.154mm, 15wt% coke and 35wt% CaCl are added 2 After mixing, make 3-15mm pellets; pellet samples are dried in a roasting furnace to a moisture content of e After magnetic separation of the permanent magnet magnetic separator, the iron ore concentrate is obtained. After the magnetic separation iron concentrate is dehydrated and dried, an iron concentrate can be obtained, and an iron concentrate product with a yield of 37.03%, an iron grade of 81.94%, a phosphorus content of 0.22%, and an iron recovery rate of 85.02% can be obtained. The beneficiation index is detailed in Table 3.

[0018] Table 1 Phase analysis of raw ore i...

Embodiment 2

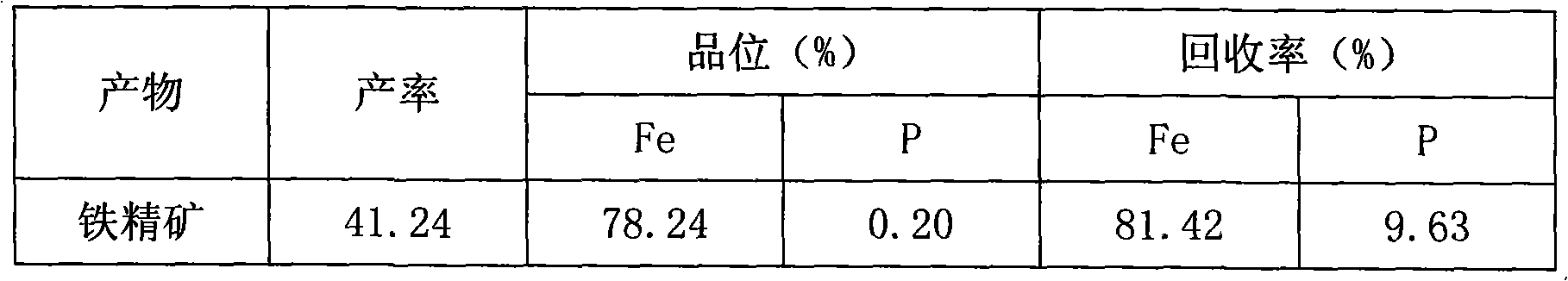

[0024] Example 2: The raw material comes from a high-phosphorus iron ore in a certain place in Yunnan. The iron is mainly iron carbonate and limonite, followed by hematite, magnetic iron, pyrite, and iron silicate. The raw ore contains about 40wt% iron, about 1wt% phosphorus, and less than 0.20wt% sulfur. Add 12% coke and 25% CaCl 2 After mixing with the powder, pellets are formed; dried in a roasting furnace, and then placed in the roasting furnace for chlorination segregation roasting, the chlorination segregation temperature is 900℃, and the chlorination segregation time is 120min; the roasted material is quenched by water Grinding and classifying to 0.074mm accounted for 70.12%, the overflow of the classifier into the magnetic field intensity is 1500O e The permanent magnetic separator obtained magnetic separation iron ore after magnetic separation. After the magnetic separation iron ore is dehydrated and dried, the iron concentrate can be obtained. The yield rate is 41.24%,...

Embodiment 3

[0032] Example 3: The raw material comes from high-phosphorus, high-sulfur, and high-arsenic oolitic hematite from a certain place in Yunnan. The sample is massive and has a relatively large hardness. The original ore has a very fine grain size and is densely distributed. Hematite occupies the main part of the sample, followed by iron carbonate, magnetic iron, pyrite, and iron silicate. The raw ore contains about 36wt% iron, about 1.90wt% phosphorus, about 1.00wt% sulfur, and about 0.10wt% arsenic. Add 15% coke and 40% CaCl 2 After mixing with the powder, the pellets are formed; the dried pellets are put into the roasting furnace for chlorination segregation roasting, the chlorination segregation temperature is 950℃, and the segregation time 75min; the roasted material is water quenched and then ground The ore is classified to -0.074mm, accounting for 78.12%; the overflow of the classifier into the magnetic field intensity is 1500O e After magnetic separation, the magnetic sepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com