A method for dephosphorizing iron ore and raising iron

A high-phosphorus iron ore and dephosphorization technology, applied in the field of smelting, can solve the problems of long processing process, achieve short process, good dephosphorization effect, and solve the effect of ore resource shortage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

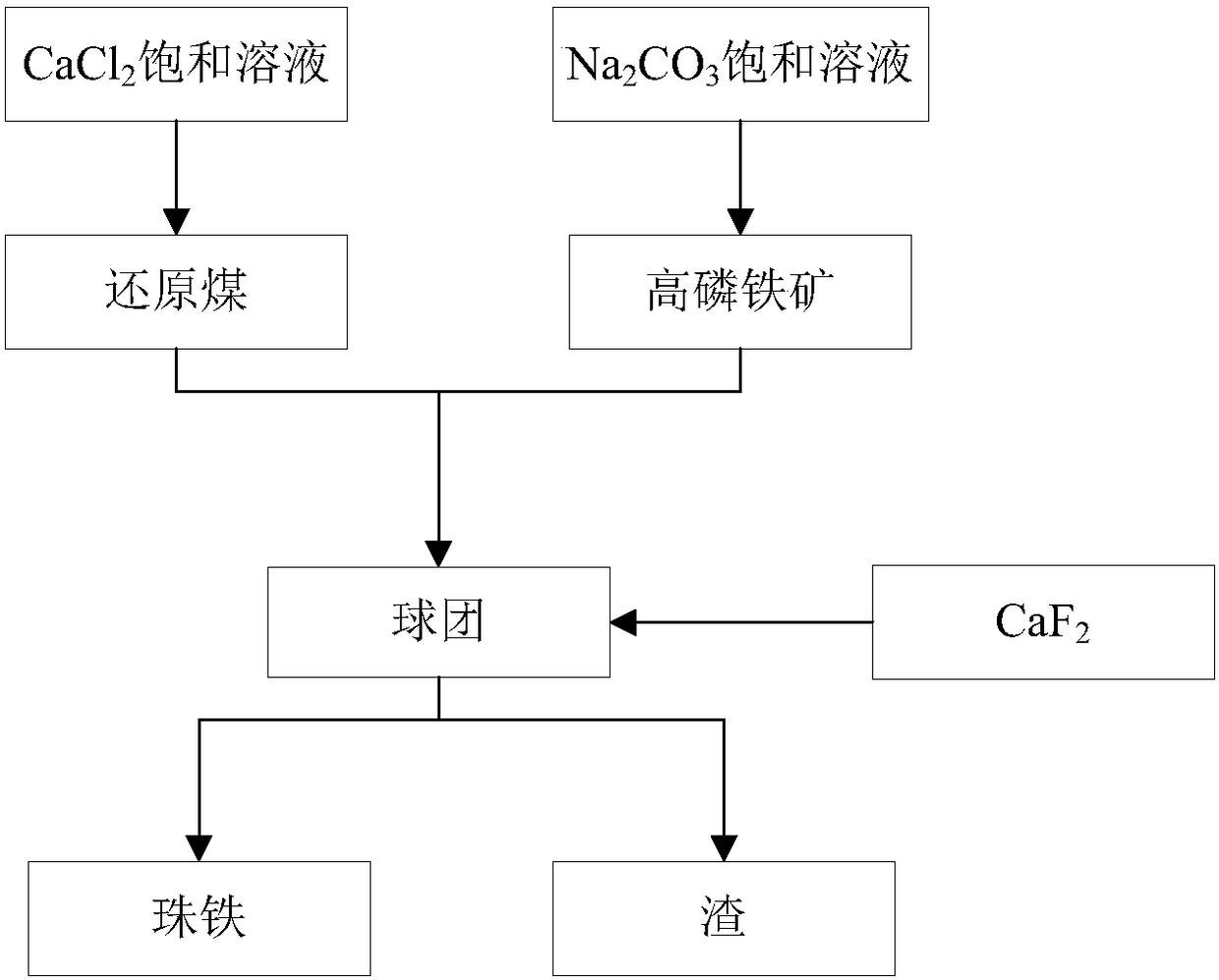

[0039] CaCl 2 The saturated aqueous solution was sprayed on the reduced coal (C: 78.1wt%) at a ratio of 100ml / 100g, dried at 105°C, and then finely ground to below 200 mesh to obtain modified reduced coal powder.

[0040] NaCO 3 Saturated aqueous solution is sprayed on high-phosphorite (TFe: 51.2wt%, P: 0.85wt%), the ratio is 6ml / 100g, dried at 130°C, and then finely ground to below 200 mesh to obtain modified high-phosphorite pink.

[0041] Mix the modified reduced coal powder and modified high-phosphorus iron ore powder according to C / O=1.2, add 5% CaF of the high-phosphorus iron ore powder mass 2 After mixing, pellets were made and dried; the dried pellets were calcined at 1400° C. for 40 minutes and air-cooled to obtain pearl iron (P: 0.18wt%) and slag.

Embodiment 2

[0043] CaCl 2 The saturated aqueous solution is sprayed on the reduced coal (C: 80.3wt%) at a ratio of 150ml / 100g, dried at 100°C, and then finely ground to below 200 mesh to obtain modified reduced coal powder.

[0044] NaCO 3 Saturated aqueous solution is sprayed on high-phosphorite (TFe: 53.6wt%, P: 0.92wt%), the ratio is 8ml / 100g, dried at 110°C, and then finely ground to below 200 mesh to obtain modified high-phosphorite pink.

[0045] Mix the modified reduced coal powder and modified high-phosphorus iron ore powder according to C / O=1.5, and add 10% CaF 2 After mixing, pellets were made and dried; the dried pellets were calcined at 1420° C. for 30 minutes and air-cooled to obtain pearl iron (P: 0.21 wt %) and slag.

Embodiment 3

[0047] CaCl 2 The saturated aqueous solution is sprayed on the reduced coal (C: 80.5wt%) at a ratio of 200ml / 100g, dried at 110°C, and then finely ground to below 200 mesh to obtain modified reduced coal powder.

[0048] NaCO 3Saturated aqueous solution is sprayed on high-phosphorite (TFe: 54.2wt%, P: 0.95wt%), the ratio is 7ml / 100g, dried at 120°C, and then finely ground to below 200 mesh to obtain modified high-phosphorite pink.

[0049] Mix the modified reduced coal powder and modified high-phosphorus iron ore powder according to C / O=1.8, and add 8% of the mass of high-phosphate iron ore powder CaF 2 After mixing, pellets were made and dried; the dried pellets were calcined at 1450° C. for 60 minutes and air-cooled to obtain pearl iron (P: 0.28 wt %) and slag.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com