Dephosphorization and iron-increasing method of high phosphorus hematite by direct reduction

A technology of hematite and hematite powder, which is applied in the field of direct reduction dephosphorization of high-phosphorus hematite, can solve the problems of low recovery rate, high cost of chemical methods, and high cost of beneficiation methods, and achieve dephosphorization rate and The iron yield is high, the residue can be recycled, and the effect of avoiding corrosion of the furnace lining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

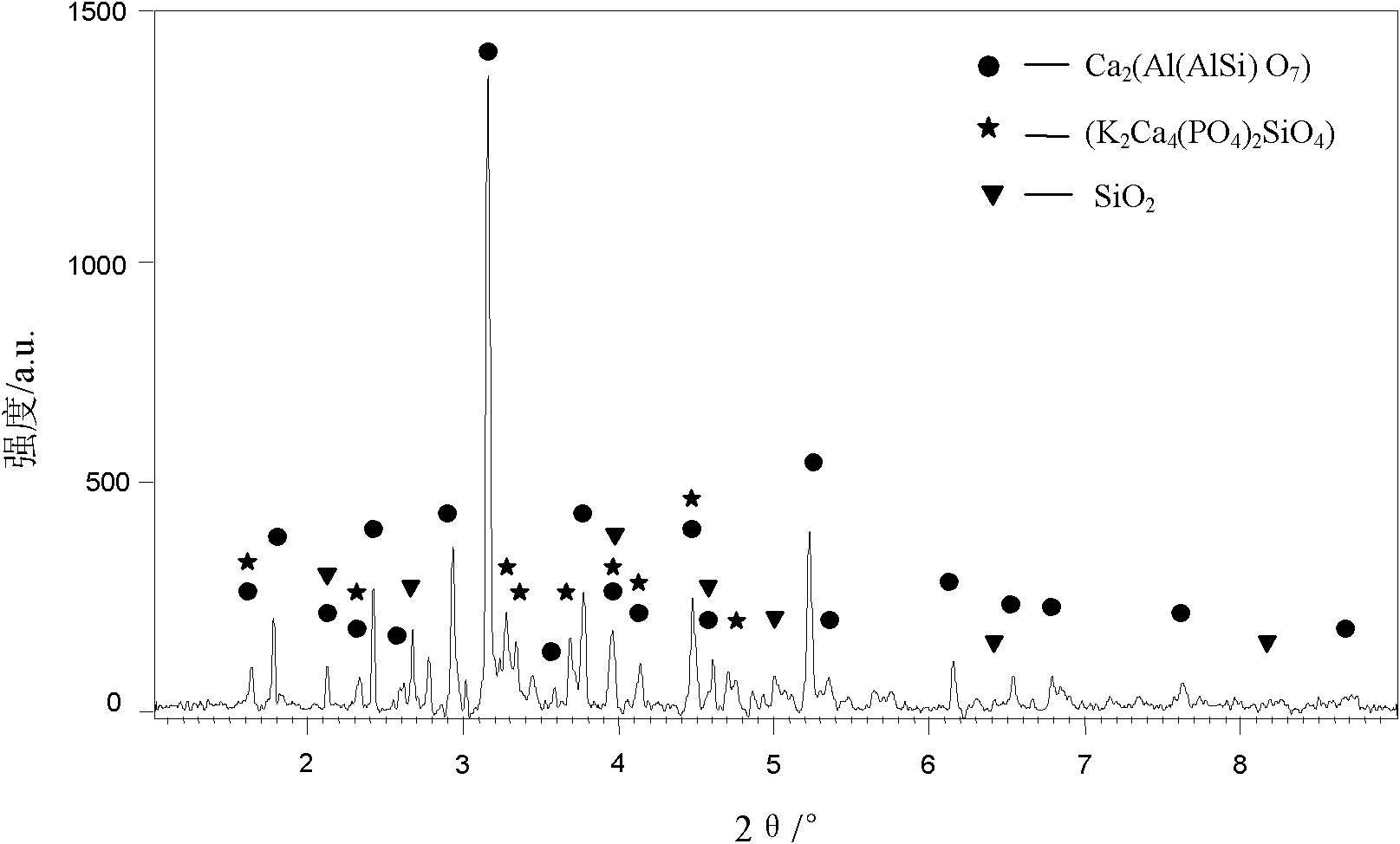

[0019] The invention discloses a method for directly reducing high-phosphorus hematite to dephosphorize and improve iron. First mix 60-70wt% high-phosphorus hematite powder, 13-15wt% carbonaceous reducing agent, 12-15wt% quicklime and 5-10wt% additives, press into agglomerates, dry, and then Reduction in the furnace at 1250-1300°C, heat preservation for 15-30 minutes; cooling down to 600-800°C with the furnace, taking out the reduced products, cooling naturally, grinding, and magnetic separation to obtain pig iron particles.

[0020] The additive in this embodiment is sodium carbonate, the high-temperature furnace is a resistance furnace, and the atmosphere in the furnace is adjusted to be a neutral atmosphere.

[0021] In this embodiment, the reduction time is short, the process is simple, the environmental pollution is small, the residue can be recycled, the dephosphorization efficiency is 82% to 90%, the carbon content in iron is 3.5% to 3.8%, and the iron yield is 85% to 9...

Embodiment 2

[0023] The invention discloses a method for directly reducing high-phosphorus hematite to dephosphorize and improve iron.

[0024] The additive in this embodiment is potassium carbonate, the high-temperature furnace is a rotary hearth furnace, and the atmosphere in the furnace is adjusted to be a neutral atmosphere. All the other are with embodiment 1.

[0025] In this embodiment, the reduction time is short, the process is simple, the environmental pollution is small, the residue can be recycled, the dephosphorization efficiency is 79% to 87%, the carbon content in iron is 3.7% to 3.9%, and the iron yield is 83% to 89%. .

Embodiment 3

[0027] The invention discloses a method for directly reducing high-phosphorus hematite to dephosphorize and improve iron.

[0028] The additive in this embodiment is a mixture of sodium carbonate and potassium carbonate, the high-temperature furnace is a rotary kiln, and the atmosphere in the furnace is adjusted to be a weakly reducing atmosphere. All the other are with embodiment 1.

[0029] In this embodiment, the reduction time is short, the process is simple, the environmental pollution is small, the residue can be recycled, the dephosphorization efficiency is 82% to 91%, the carbon content in iron is 3.6% to 4.1%, and the iron yield is 87% to 91%. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com