Method for preparing ilmenite by ilmenite carbothermic-electrolysis

A technology of ferro-titanium and ilmenite, which is applied in the field of electrochemical metallurgy, can solve the problems of lack of consideration of cost, energy consumption, and environmental protection, and achieve the effects of reducing electrolysis energy consumption, low process energy consumption, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

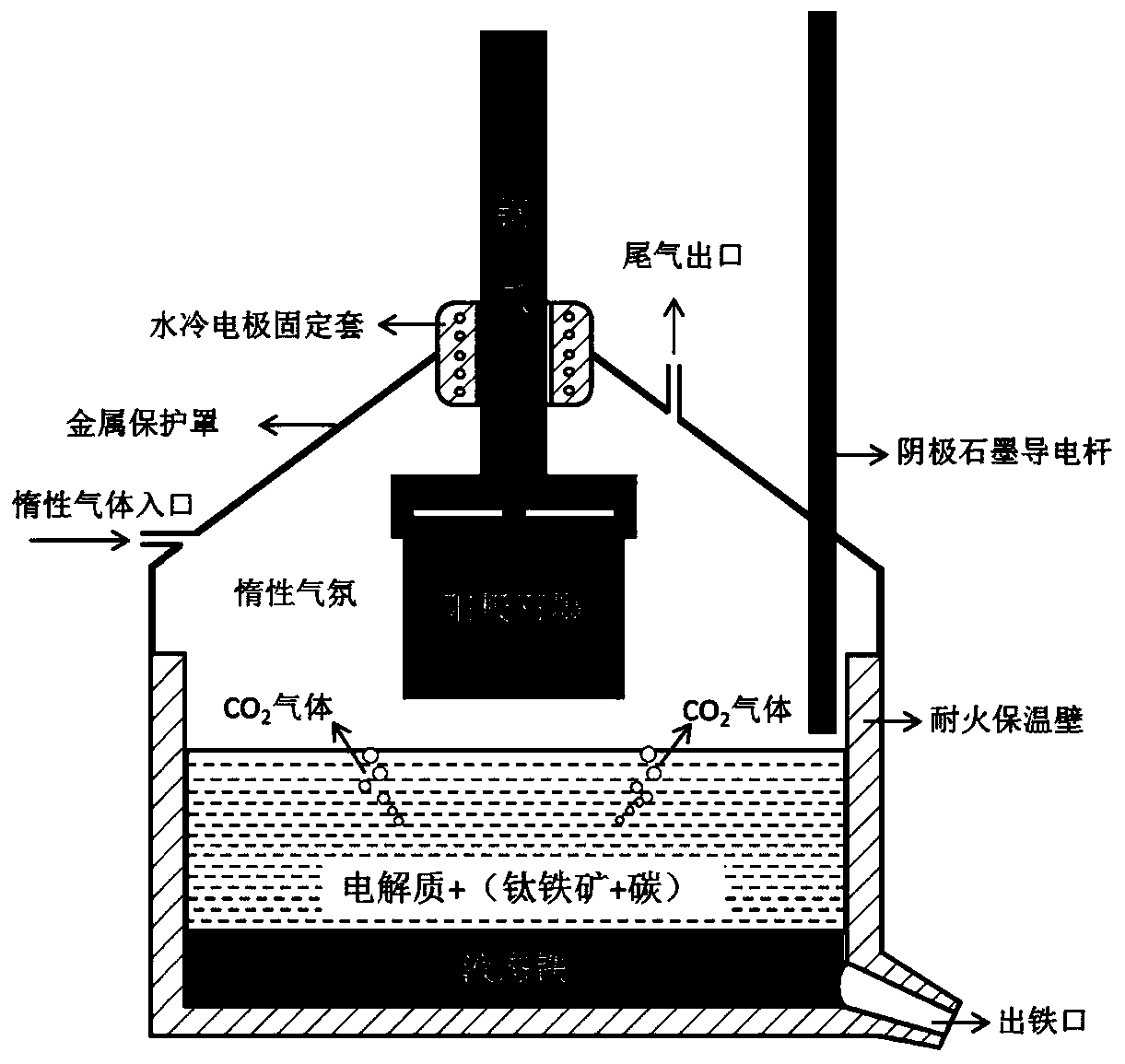

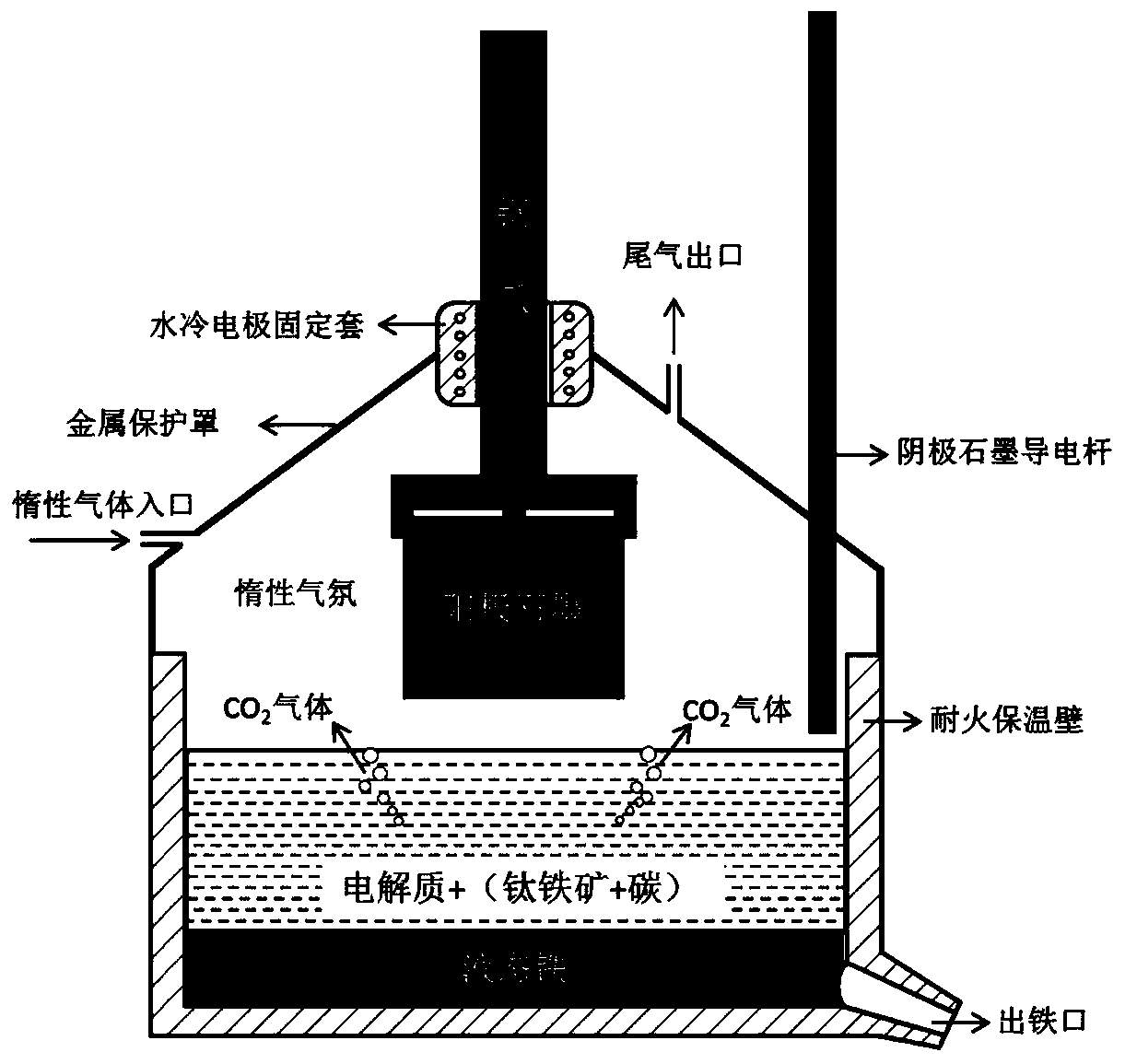

Embodiment 1

[0025] Chenggang ilmenite sand and coke are ball milled and mixed at a molar ratio of 2:1, and then added to CaO-Al at 1700°C 2 o 3 In the molten electrolyte, the electrolysis starts after keeping warm until the coke is globally oxidized. Under the protection of argon, the graphite anode is immersed in the electrolyte, the cathode conductive rod is inserted into the molten iron obtained by carbothermal reduction, and the molten iron is used as the cathode. Using constant current electrolysis process, the cathode current density is 1A / cm 2 , the anode current density is 0.5A / cm 2 , Electrolyzed to 20% titanium content in molten iron to stop electrolysis. The liquid titanium-iron alloy is discharged through the iron tap, and the temperature is lowered to room temperature under the protection of argon to obtain a low-titanium-iron alloy product. figure 1 It is the schematic diagram of carbothermal reduction-electrolysis of ilmenite in this example.

Embodiment 2

[0027] The ilmenite sand in Panzhihua area is mixed with coal according to the molar ratio of 2:1, and then added to CaO-Al at 1600°C 2 o 3 -In the CaF molten electrolyte, keep warm until the coal is oxidized globally and start electrolysis. Under the protection of argon, the graphite anode is immersed in the electrolyte, the cathode conductive rod is inserted into the molten iron obtained by carbothermal reduction, and the molten iron is used as the cathode. Using constant current electrolysis process, the cathode current density is 0.5A / cm 2 , the anode current density is 0.25A / cm 2 , Electrolyze until the titanium content in the molten iron is 50% and stop the electrolysis. The liquid titanium-iron alloy is discharged through the iron tap, and the temperature is lowered to room temperature under the protection of argon to obtain a medium titanium-iron alloy product.

Embodiment 3

[0029] Ilmenite sand and coke in Panzhihua area were mixed by ball milling at a molar ratio of 3:1, and then added to CaO-Al at 1800 °C 2 o 3 In the molten electrolyte, the electrolysis starts after keeping warm until the coke is globally oxidized. Under the protection of argon, the graphite anode is immersed in the electrolyte, the cathode conductive rod is inserted into the molten iron obtained by carbothermal reduction, and the molten iron is used as the cathode. The constant voltage electrolysis process is adopted, the electrolysis voltage is 5V / cm, and the electrolysis is stopped when the content of titanium element in the electrolyte is as low as 0.1%. And add the mixture of ilmenite and coke to the electrolysis again to continue the carbothermal-electrolysis cycle until the electrolysis is stopped when the titanium content in the molten iron reaches 80%. The liquid titanium-iron alloy is discharged through the iron tap, and the temperature is lowered to room temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com