A refining agent adding device and adding method

A technology of adding devices and refining agents, which is applied in the field of alloy smelting, can solve problems such as iron increase or poor refining effect, and achieve the effects of improving refining effect, uniform distribution, and improving the uniformity of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

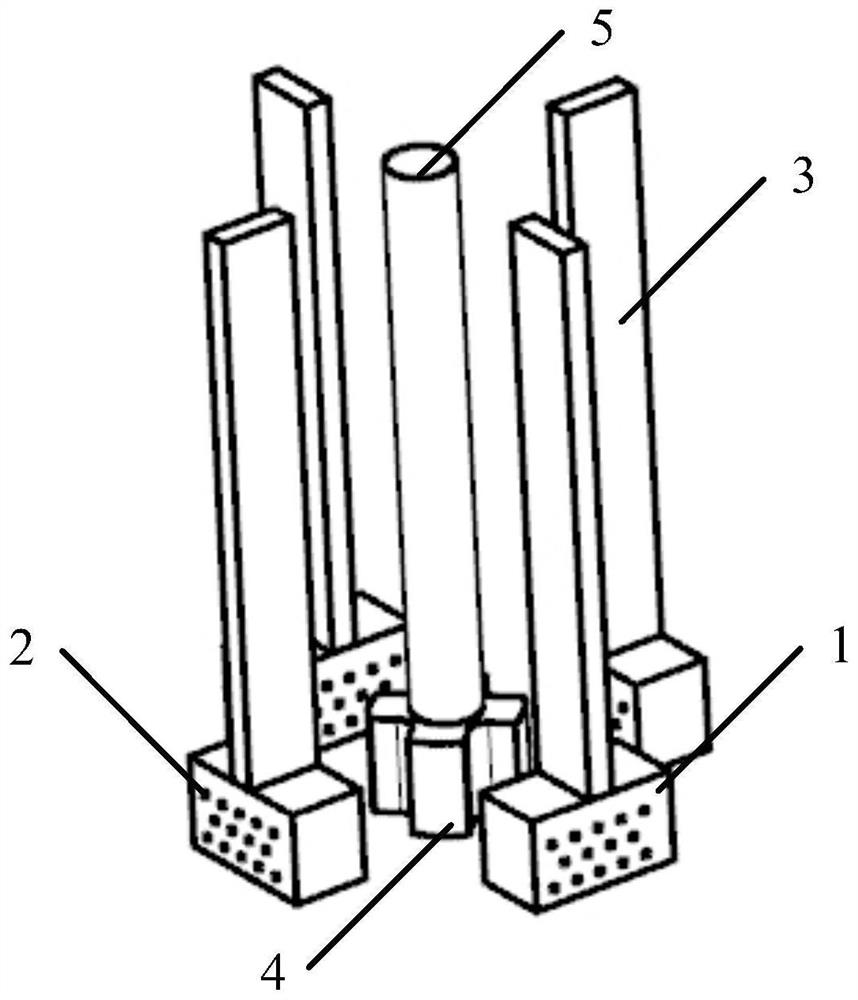

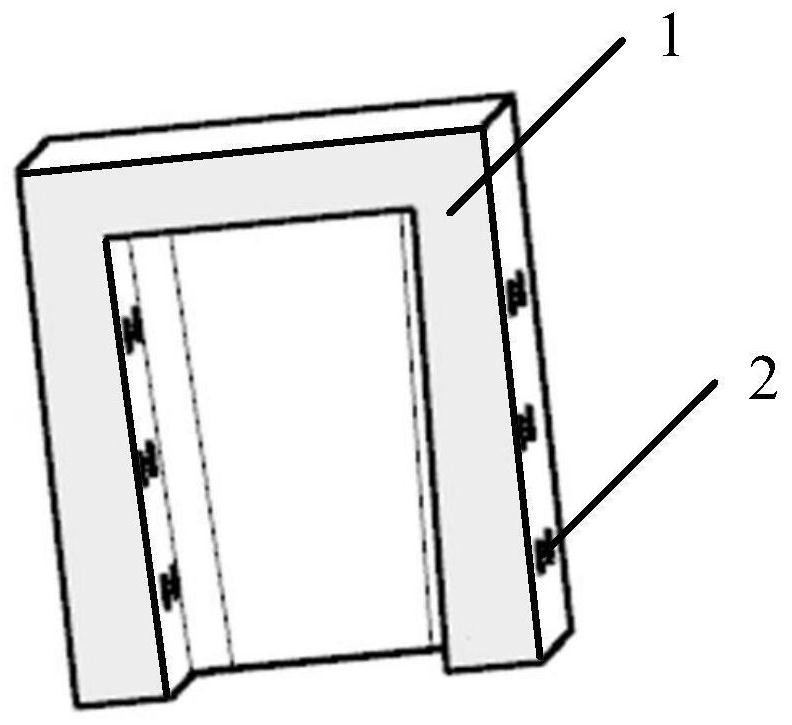

[0048] This embodiment provides a device for adding refining agent, see Figure 1 to Figure 2 , including a storage tank 1, a stirring mechanism, and a lifting mechanism (not shown in the figure) for driving the storage tank 1 and the stirring mechanism to lift. For example, aluminum alloy refining agent, the slot of the storage tank 1 and the through hole 2 serve as the circulation channel of the refining agent.

[0049] During implementation, the lifting mechanism is activated, and the lifting mechanism drives the storage tank 1 and the stirring mechanism to move toward the molten pool, and finally enters the molten pool, close to the bottom of the molten pool; close the lifting mechanism, open the stirring mechanism, and under the stirring action of the stirring mechanism, The melt in the molten pool flows between the inside and outside of the storage tank 1, and at the same time, the refining agent in the storage tank 1 is taken out of the storage tank 1 and dissolved in t...

Embodiment 2

[0072] This embodiment provides a method for adding a refining agent, using the method for adding a refining agent provided in Embodiment 1, and the above-mentioned adding method includes the following steps:

[0073] Step S1: start the lifting mechanism, the lifting mechanism drives the storage tank 1 and the stirring mechanism to move towards the direction close to the molten pool, and enters the molten pool, close to the bottom of the molten pool;

[0074] Step S2: closing the lifting mechanism, opening the stirring mechanism, and under the stirring action of the stirring mechanism, the refining agent in the storage tank 1 is taken out of the storage tank 1 and dissolved in the melt, thereby completing the addition of the refining agent.

[0075] Compared with the prior art, the beneficial effects of the refining agent adding method provided in this embodiment are basically the same as the beneficial effects of the refining agent adding device provided in the first embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com