Microwave continuous suspension roasting method of enhancing high-phosphorus oolitic hematite for iron increase and phosphorus reduction

A technology of oolitic hematite and suspension roasting, which is applied in the field of mineral processing, can solve the problems of insignificant separation indicators of high-phosphorus oolitic hematite, achieve a significant effect of increasing iron and reducing phosphorus, and realize resource utilization and high efficiency , to achieve the effect of development and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

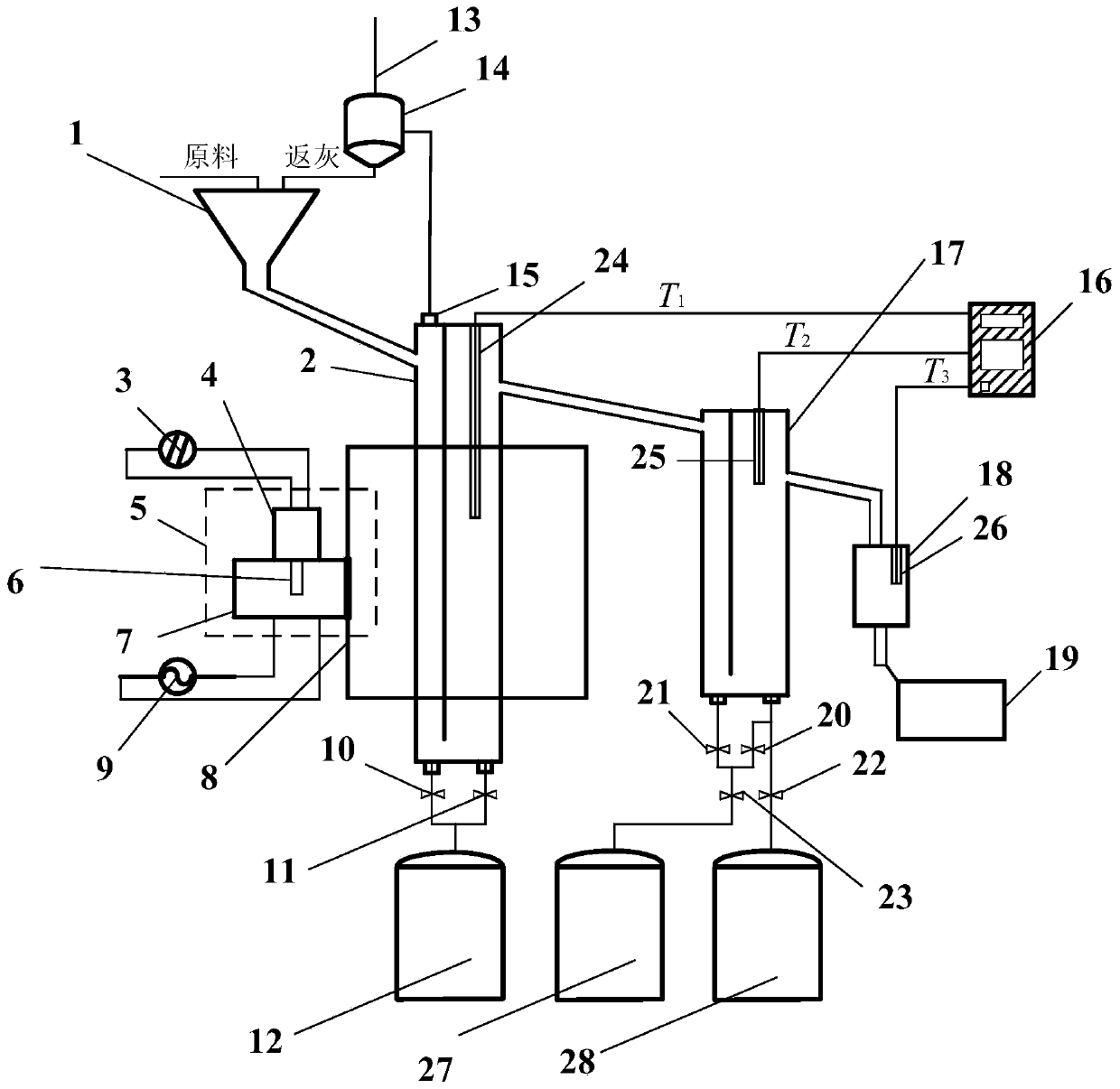

[0056] The structure of the microwave continuous suspension roasting system is as follows: figure 1 As shown, it includes feeding bin 1, pretreatment fluidizer 2, microwave cavity 8, microwave generating device 5, reduction fluidizer 17, cooler 18 and collection tank 19;

[0057] The discharge port at the bottom of the feeding bin 1 is connected with the feed port of the pretreatment fluidizer 2, and the pretreatment fluidizer 2 is provided with a microwave cavity 8 outside, and a pretreatment baffle is arranged inside the pretreatment fluidizer 2 The interior is divided into a pretreatment feed chamber and a pretreatment discharge chamber. The top edge of the pretreatment baffle is connected to the top plate of the pretreatment fluidizer 2, and the two sides of the pretreatment baffle are connected to the pretreatment fluidizer 2. The side wall is connected, and the gap between the bottom edge of the pretreatment baffle and the bottom plate of the pretreatment fluidizer 2 is ...

Embodiment 2

[0083] System structure is the same as embodiment 1, and the difference is:

[0084] (1) The gas in the first gas storage tank is CO 2 ; The gas in the second gas storage tank is CO 2 , N in the gas in the third gas storage tank 2 The volume percentage is 20%, and the rest is H 2 ;

[0085] (2) The volume ratio of the pretreatment feed chamber to the pretreatment discharge chamber is 1:5, the height ratio of the pretreatment baffle to the pretreatment fluidizer 2 is 1:1; the reduction feed chamber and the reduction discharge chamber The volume ratio is 1:5, and the height ratio between the reduction baffle and the reduction fluidizer 17 is 1:1;

[0086] Method is with embodiment 1, and difference is:

[0087] (1) Particle size of iron ore powder ≤ 0.074mm accounts for 70% of the total mass;

[0088] (2) The ratio of the total volume of protective gas passing into the pretreatment feed chamber and the pretreatment discharge chamber per unit time to the mass of iron ore po...

Embodiment 3

[0094] System structure is the same as embodiment 1, and the difference is:

[0095] (1) N in the gas in the third gas storage tank 2 The volume percentage is 30%, the rest is CH 4 ;

[0096] (2) The volume ratio of the pretreatment feed chamber to the pretreatment discharge chamber is 1:8, the height ratio of the pretreatment baffle to the pretreatment fluidizer is 1:1.5; the reduction feed chamber to the reduction discharge chamber The volume ratio is 1:8, and the height ratio of the reduction baffle to the reduction fluidizer is 1:1.5;

[0097] Method is with embodiment 1, and difference is:

[0098] (1) Particle size of iron ore powder ≤ 0.074mm accounts for 90% of the total mass;

[0099] (2) The ratio of the total volume of protective gas passing into the pretreatment feed chamber and the pretreatment discharge chamber per unit time to the mass of iron ore powder passing into the pretreatment feed chamber is 7m 3 / kg, the volume ratio of the protective gas passing i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com