Industrial production method for conducting iron increase and phosphorous reduction on high-phosphorus oolitic hematite

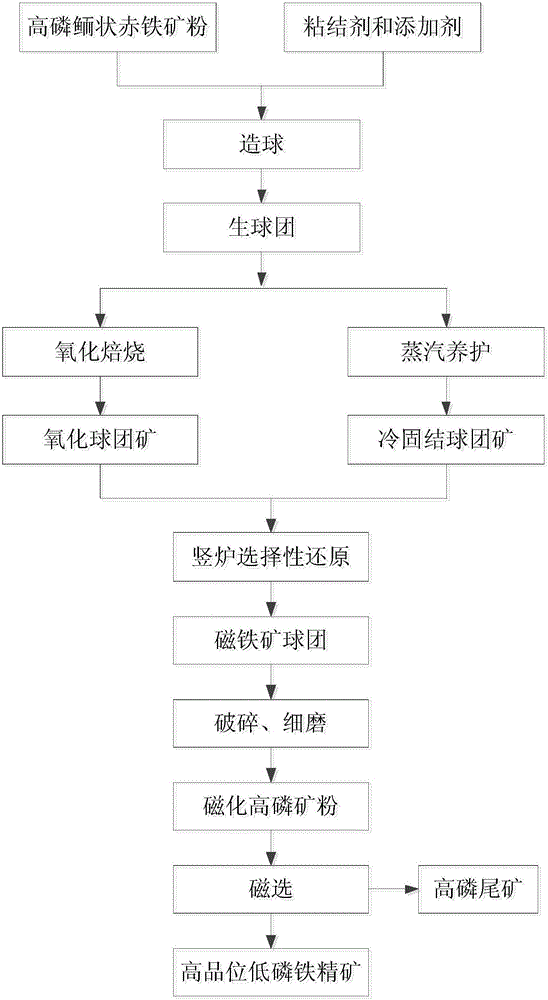

An oolitic hematite and high-phosphorus technology, applied in the field of metallurgy, can solve the problems of restricting the development and utilization of high-phosphorus oolitic hematite resources, difficult to realize large-scale application, economically unfeasible, etc., and achieve the goal of being suitable for large-scale industry Production, realization of large-scale industrial application, loose structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0033] The present embodiment is basically the same as embodiment 1, and the difference is that the chemical composition of high phosphorus oolitic hematite is mainly: Fe 2 o 3 38.03wt%, Al 2 o 310.87wt%, SiO 2 18.26wt%, CaO6.90wt%, P1.2wt%, mix high-phosphorus oolitic hematite, bentonite, dephosphorization agent and water, and use a briquetting machine to make green ore with a diameter of 8-15mm. The roasting temperature is 1000°C, and the roasting time is 30min; the proportion of CO in the mixed gas fed into the reduction section is 20%, the temperature of the mixed gas is 850°C, the CO content in the top gas is 7%, and the volume of the top gas is 86% % returns to the mixed gas tank, and 14% returns to the heat exchanger as fuel gas. The porosity of the reduced magnetite pellets is 40%, and the structure is loose; the grade of the iron concentrate after magnetic separation is 63%, the P content in the iron concentrate is 0.06%, and the recovery rate of iron is 92%.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com