Geotechnical engineering anti-blast structure model test device

A technology of model test device and structural model, which is applied in the direction of machine/structural component testing, measuring device, soil material testing, etc. It can solve the problems of large model size, limited explosion types, unrealizable operation, etc., and achieve scientific and reasonable cross-sectional shape , Improve the anti-knock ability and save test funds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

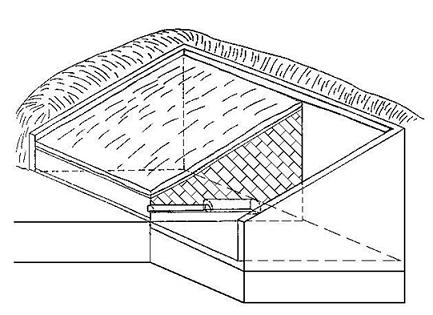

[0041] Such as Figure 6-10 As shown, a model test device for anti-blast structure of geotechnical engineering, the model test device is composed of side-limited boxes 22, 23, 24, 25 and the explosion pit 27 at the bottom. Seen from the plane, the whole device is approximately ten font, and is provided with a supporting wave elimination mechanism, a locking mechanism and a sliding positioning mechanism; the four side-limited boxes 22, 23, 24, 25 are arranged vertically opposite to each other, and the four side-limited boxes The structure is the same, but the lengths are different, the lengths are 2.4m and 1.5m respectively, and a circular observation hole 28 is arranged along the width direction at the middle length of the two side-limited boxes with longer lengths, and camera equipment can be installed therein. Used to observe the test phenomenon; the four side-limited boxes facing each other and vertically arranged are arranged on the edge of the underground explosion crater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com