Grinding burning-rate accelerator for coal, preparation method and application thereof

A combustion-supporting agent and coal technology, which is applied in the field of coal grinding-assisting combustion-supporting agent and its preparation and application, can solve the problems of no use value, ineffectiveness, economical inefficiency, etc., achieves strong diffusivity and penetration, and improves quality , The effect of reducing the fineness of pulverized coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

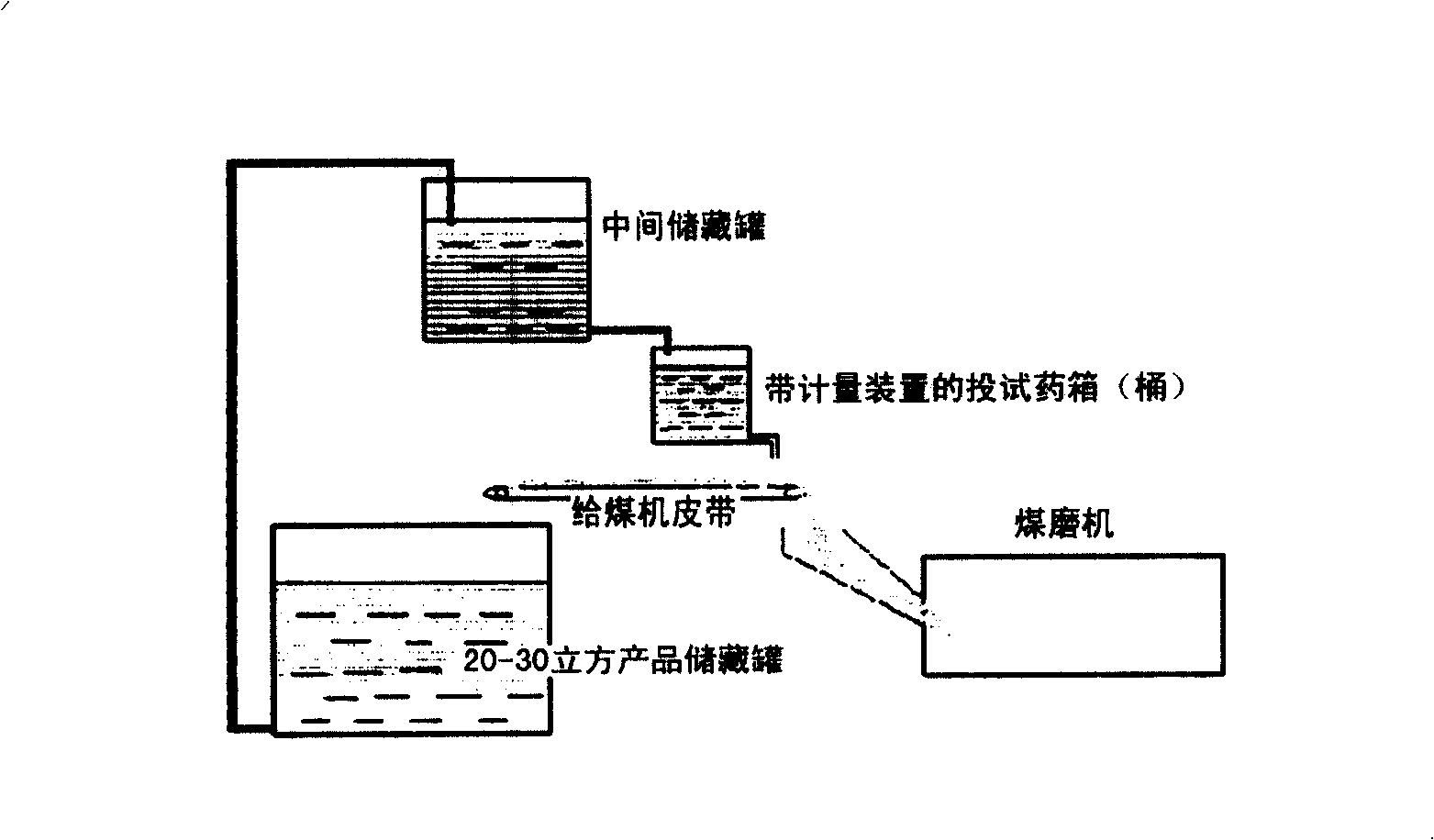

Image

Examples

Embodiment 1

[0046] A coal grinding and combustion accelerant is prepared from the following raw materials: 45 kg of combustion oil, 23 kg of soybean oil, 20 kg of emulsifier, and 15 kg of hydrophilic surfactant.

[0047] Its preparation steps are as follows:

[0048] ①Manufacture of emulsifier

[0049] The weight ratio of each component of the emulsifier is: 17 kg of paraffin, 1 kg of naphthol, 1 kg of stearic acid, 1 kg of polyvinyl alcohol, 3 kg of dipropylamine, 0.5 kg of sodium dodecylbenzenesulfonate, sulfonated humic acid 3 kilograms of sodium bicarbonate, 2 kilograms of alkanolamine, 60 kilograms of water;

[0050] First add the above-mentioned other components except naphthol into the water, heat up to 100°C, stir, and keep for 1-2 hours to completely dissolve the solute, then add naphthol; continue stirring until the naphthol dissolves to obtain an emulsifier solution;

[0051] ② Preparation of hydrophilic surfactant

[0052] Mix 1 kg of lipophilic vegetable oil and 1 kg of n-...

Embodiment 2

[0057] A coal grinding and combustion accelerant, the preparation steps of which are as follows:

[0058] A coal grinding and combustion accelerant is prepared from the following raw materials: 50 kg of machine oil, 20 kg of pine charcoal oil, 18 kg of emulsifier, and 12 kg of hydrophilic surfactant.

[0059] ①Manufacture of emulsifier

[0060] The weight ratio of each component of the emulsifier is: 19 kg of paraffin, 2 kg of naphthol, 3 kg of stearic acid, 2 kg of polyvinyl alcohol, 4 kg of dipropylamine, 1 kg of sodium dodecylbenzenesulfonate, sulfonated humic acid 5 kilograms of sodium bicarbonate, 5 kilograms of alkanolamine, 59 kilograms of water;

[0061] First add the above-mentioned other components except naphthol into the water, heat up to 100°C, stir, and keep for 1-2 hours to completely dissolve the solute, then add naphthol; continue stirring until the naphthol dissolves to obtain an emulsifier solution;

[0062] ② Preparation of hydrophilic surfactant

[0063...

Embodiment 3

[0067] A coal grinding and combustion accelerant, the preparation steps of which are as follows:

[0068] A coal grinding and combustion accelerant is prepared from the following raw materials: 55 kg of lubricating oil, 23 kg of palm oil, 20 kg of emulsifier, and 14 kg of hydrophilic surfactant.

[0069] ①Manufacture of emulsifier

[0070] The weight ratio of each component of the emulsifier is: 23 kg of paraffin, 4 kg of naphthol, 5 kg of stearic acid, 3 kg of polyvinyl alcohol, 6 kg of dipropylamine, 1.5 kg of sodium dodecylbenzenesulfonate, sulfonated humic acid 7 kilograms of sodium bicarbonate, 6 kilograms of alkanolamine, 60 kilograms of water;

[0071] First add the above-mentioned other components except naphthol into the water, heat up to 100°C, stir, and keep for 1-2 hours to completely dissolve the solute, then add naphthol; continue stirring until the naphthol dissolves to obtain an emulsifier solution;

[0072] ② Preparation of hydrophilic surfactant

[0073] M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com