Polyacrylonitrile mesopore-macropore ultrafine carbon fiber and its preparation method

A technology of polyacrylonitrile-based mesoporous and ultra-fine carbon fibers, which is applied in the fields of fiber chemical characteristics, chemical instruments and methods, and other chemical processes. It can solve the problems that fibers do not have a porous structure, and achieve large specific surface area and small fiber diameter. , easy to adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

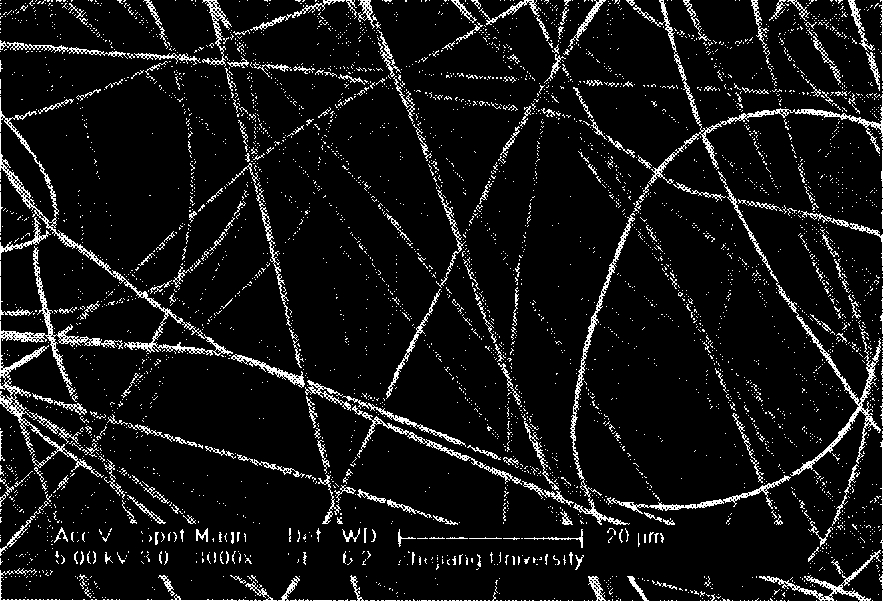

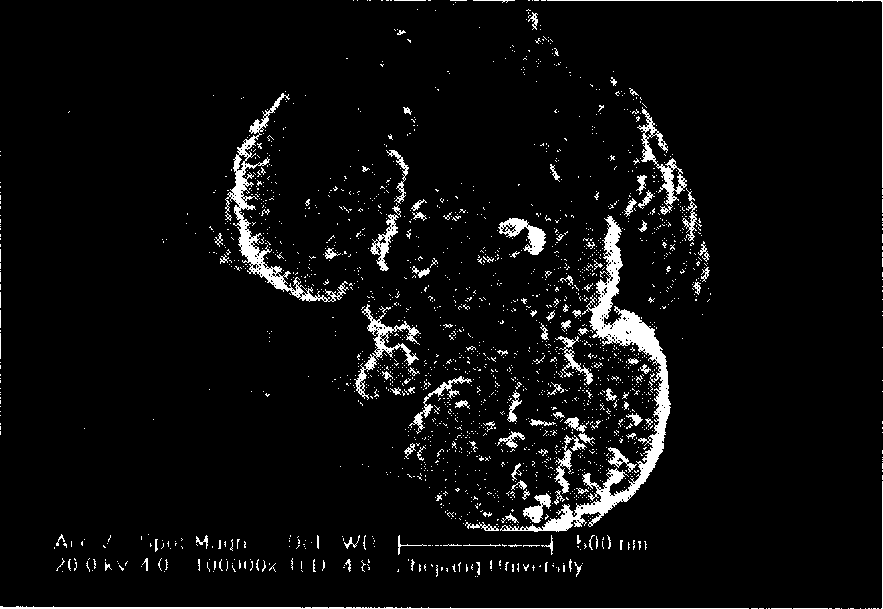

[0021] 4 grams of polyacrylonitrile and 6 grams of acrylonitrile-methyl methacrylate copolymer with a composition ratio of 1:9 were dissolved in 250 grams of dimethylformamide solution and obtained by high-voltage electrospinning to obtain superfine fibers, fiber mats or non-woven fabrics. spinning. The spinning voltage was 30,000 volts and the spinning speed was 0.5 ml / hour. The distance between the spinneret and receiver was 15 cm. The resulting electrospun fibers are shown in figure 1 , the diameter of the fiber is about 100 to 500 nm. The fiber mat obtained by electrospinning was vacuum-dried at 80°C, then pre-oxidized at 280°C for 2 hours, then slowly heated to 800°C under the protection of nitrogen, and kept for 1 hour, and the flow rate of nitrogen was 10 ml / min. Among them, the pyrolyzable polymer is completely decomposed to obtain mesoporous-macroporous ultrafine carbon fibers, such as figure 2 As shown, the diameter of the carbon fiber is below 500 nm. A large ...

Embodiment 2

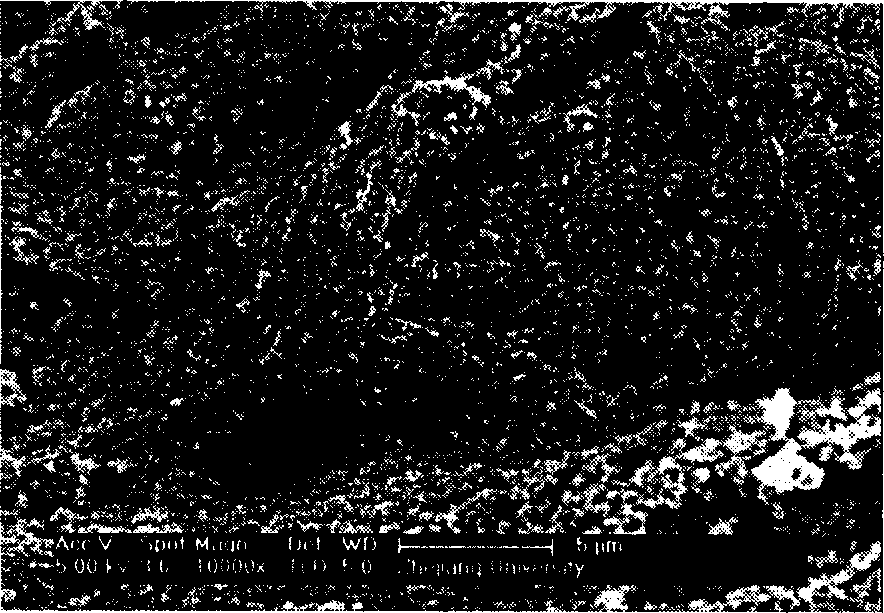

[0023] 2 grams of polyacrylonitrile and 8 grams of acrylonitrile-methyl methacrylate-polystyrene copolymer with a composition ratio of 1:8.5:0.5 were dissolved in 250 grams of dimethyl sulfoxide solution, and high-voltage electrospinning was used to obtain fibers felt. The spinning voltage was 30,000 volts and the spinning speed was 2 ml / hour. The distance between the spinneret and receiver was 15 cm. Drying and pre-oxidation are the same as in Example 1, the carbonization temperature is 700° C., and the time is 2 hours. After carbonization, the fibers are obviously porous and adhere to each other (see image 3 shown). Its specific surface area was 92 m2 / g as measured by the nitrogen adsorption method. The obtained mesoporous-macroporous ultrafine carbon fiber was activated with carbon dioxide at 800° C., and the specific surface area was measured as 245 square meters per gram by nitrogen adsorption method.

Embodiment 3

[0025] 5 grams of polyacrylonitrile and 5 grams of acrylonitrile-methyl methacrylate-butyl methacrylate terpolymer with a composition ratio of 1:8:1 were dissolved in 250 grams of dimethylacetamide solution, Spinning obtains a fiber mat. The spinning voltage was 20,000 volts and the spinning speed was 5 ml / hour. The distance between the spinneret and receiver was 15 cm. Drying and pre-oxidation are the same as in Example 1, the carbonization temperature is 1000° C., and the time is 2 hours. The diameter of the fibers is 5 microns. The fiber contains a large number of micropores, and the diameter of the pores is about 100 nanometers. Its specific surface area was measured by nitrogen adsorption method to be 54 m2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com