Preparation method and device for three-dimensional support for spinning by utilizing gas-electro spinning based on negative-pressure collection

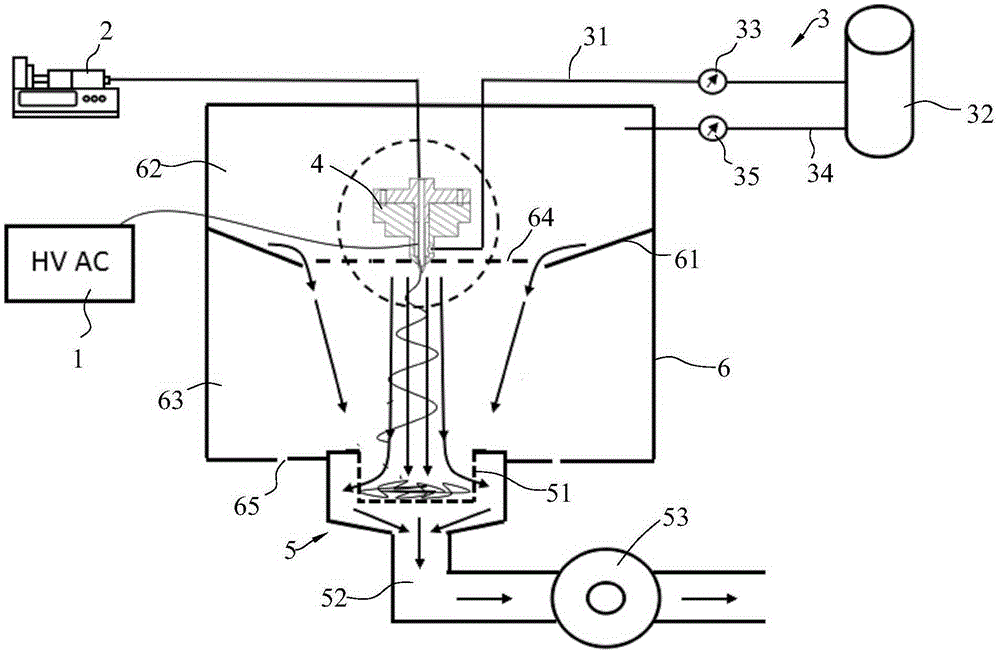

A three-dimensional support, negative pressure collection technology, applied in fiber processing, textile and papermaking, filament/thread forming, etc., can solve the problems of difficult three-dimensional structure, low electrospinning efficiency, high jet starting voltage, and achieve controllable airflow path. The effect of enhanced performance, simple device structure and stable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] A method for preparing a three-dimensional air electrospinning scaffold based on negative pressure collection, comprising the following steps:

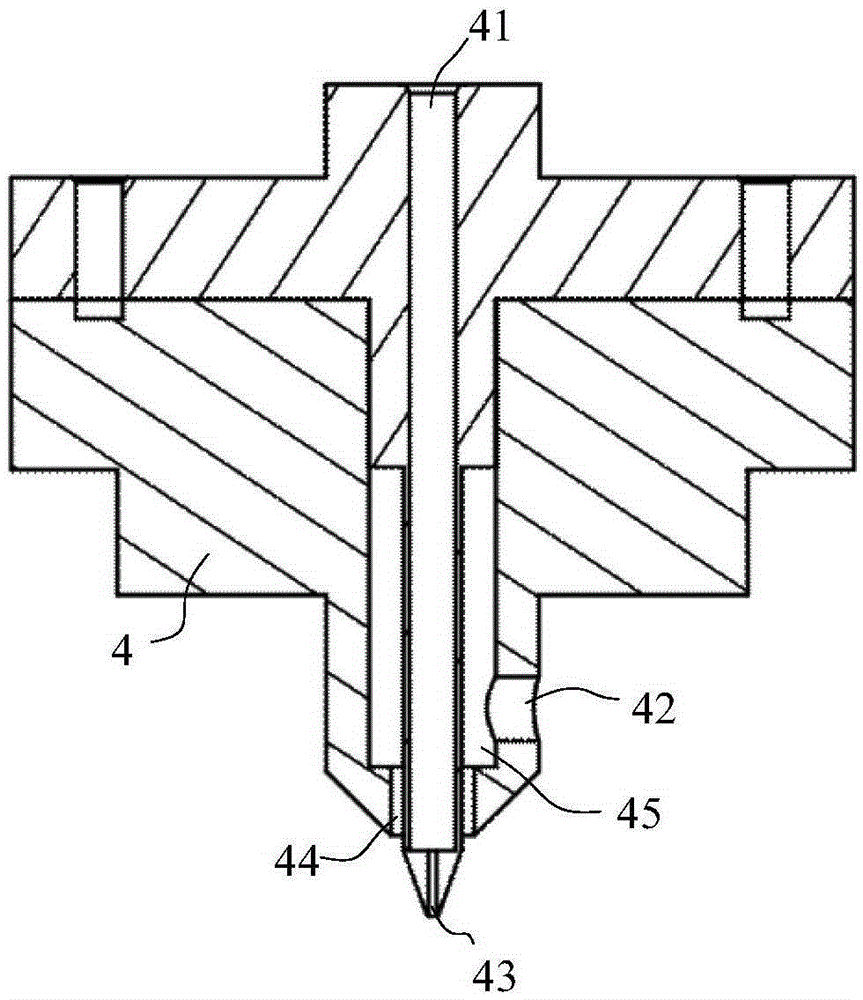

[0048] S10. The liquid supply device 2 can provide spinning solution or melt, open the liquid supply device 2, the spinning solution or melt enters the coaxial nozzle 4 from the liquid supply channel 41 and flows out from the liquid outlet 43 of the coaxial nozzle 4;

[0049] S20. Adjust the AC high-voltage generator 1 to output voltages with appropriate waveforms, frequencies, amplitudes, and bias values, and form an alternating electric field between the coaxial nozzle 4 and the negative pressure receiving device 5;

[0050] S30. Open the negative pressure generator 53 and the air pressure supply device 32; adjust the air pressure supply device 32 to provide the gas with flow velocity, temperature and humidity, and the gas flows through the gas supply channel 42 of the first gas delivery pipe 31 and the coaxial nozzle 4, and f...

Embodiment 1

[0055] 1. Preparation of spinning solution, weigh 1200 mg PLLA (molecular weight = 200,000 Daltons), dissolve in 20 ml (9:1, CH 2 Cl 2 / DMF, v / v) solvent, prepared 6% PLLA solution, sealed with parafilm, magnetically stirred for 4 hours, and set aside.

[0056] 2. Adjust the parameters of the liquid supply device, the capacity is 15 ml, the propulsion speed is 5 ml / hour, and it is running. Deliver the PLLA solution to the coaxial nozzle 4, enter the liquid outlet 43 from the liquid supply channel 41, and the diameter of the liquid outlet 3 is 0.3 mm;

[0057] 3. Adjust the AC high-voltage generator 1, the output frequency is 100Hz, and the peak-to-peak value is 8KV sinusoidal high-voltage AC;

[0058] 4. Open the negative pressure receiving device 5; open the gas supply device 3, adjust the air pressure to 0.75MPa, adjust the gas temperature to 30°C, the hot gas flows through the gas supply channel 42, and finally sprays out from the gas outlet 44,

[0059] 5. Under the joi...

Embodiment 2

[0063] In this case, using polylactic acid as raw material, the specific process of applying a three-dimensional fiber scaffold preparation method and device based on AC air electrospinning is as follows:

[0064] 1. Using polylactic acid as raw material, add 10 grams of polylactic acid into the liquid supply device 2. After the polylactic acid is heated to a molten state in the liquid supply device 2, the polylactic acid melt is transported to the coaxial nozzle 4, and the liquid supply channel 41 enters the liquid outlet 43, and the diameter of the liquid outlet is 0.5 mm;

[0065] 2. Adjust the AC high-voltage generator 1, the output frequency is 90Hz, and the peak-to-peak value is 10KV sinusoidal high-voltage AC;

[0066] 3. Open the negative pressure receiving device 5; open the air supply device 3, adjust the air pressure to 0.9MPa, adjust the airflow temperature to 190°C, the hot air flows through the air supply channel 42, and finally sprays out from the air outlet 44; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com