Preparing method of silicon dioxide aerogel nanofiber composite membrane

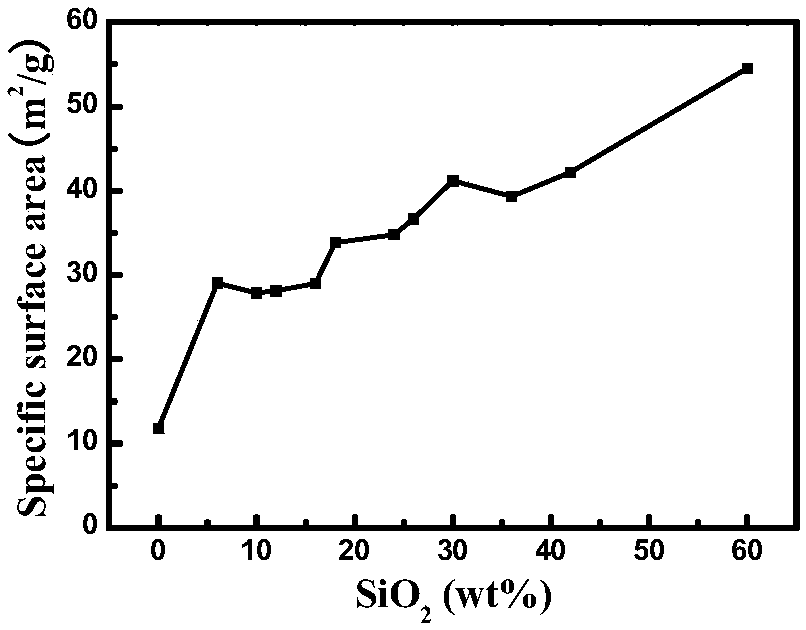

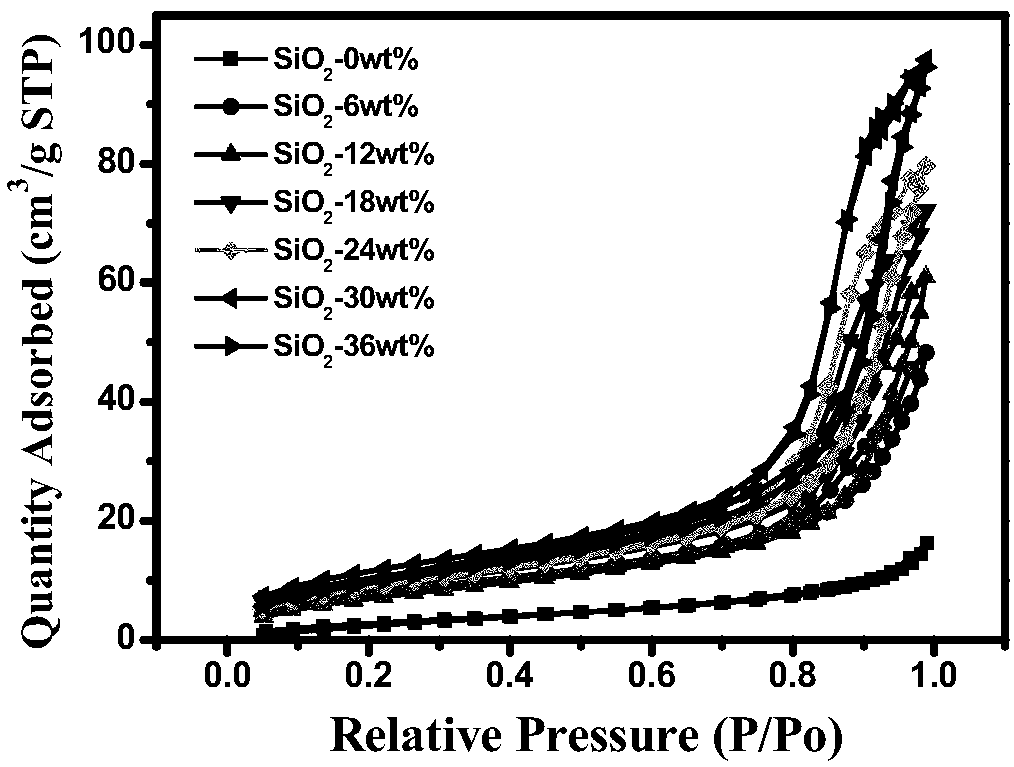

A technology of silica and nanofibers, which is applied in fiber treatment, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of silica airgel aggregation, complicated process routes, and destruction of porous structures, so as to achieve easy processing, The effect of simple process and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing a silica airgel nanofiber composite membrane, comprising the steps of:

[0028] 1)SiO2 2 / Preparation of formic acid dispersion: at room temperature, weigh 20.25g of 88% formic acid; add 0.54g of silica airgel powder to formic acid in batches in small amounts, and oscillate ultrasonically for 15 minutes until uniformly dispersed , to obtain a dispersion of silica airgel;

[0029] 2) PA6 / SiO2 2 Preparation of spinning solution: Weigh 3g of dried PA6 resin and 6.75g of acetic acid, add it to the dispersion of silica airgel, stir magnetically at room temperature for 12h until the PA6 resin is completely dissolved, let it stand for defoaming, and obtain the silica airgel Silica airgel content is the electrospinning solution of 18wt%;

[0030] 3) PA6 / SiO2 2 Electrospinning: Use the self-assembled electrospinning nanofiber equipment as the spinning device, and use a 10ml medical syringe to extract the prepared PA6 / SiO 2 solution, choose 8# flat ne...

Embodiment 2

[0033] A method for preparing a silica airgel nanofiber composite membrane, comprising the steps of:

[0034] 1)SiO2 2 Preparation of the formic acid dispersion: at room temperature, weigh 13.5 g of 88% formic acid. Add 0.48g of silica airgel powder to formic acid in batches in a small amount and multiple times, and ultrasonically oscillate for 20 minutes until uniformly dispersed to obtain a dispersion of silica airgel;

[0035] 2) PA66 / SiO2 2 Preparation of spinning solution: Weigh 2g of dried PA66 resin and 4.5g of acetic acid and add it to the dispersion of silica airgel, stir magnetically at room temperature for 12 hours until the PA66 resin is completely dissolved, and stand for defoaming to obtain silica An electrospinning solution with an airgel content of 24% by weight;

[0036] 3) PA66 / SiO2 2 Electrospinning: Use the self-assembled electrospinning nanofiber equipment as the spinning device, and use a 10ml medical syringe to extract the prepared PA6 / SiO 2 solutio...

Embodiment 3

[0039] A method for preparing a silica airgel nanofiber composite membrane, comprising the steps of:

[0040] 1)SiO2 2 / Preparation of hexafluoroisopropanol dispersion: weigh 13.5 g of hexafluoroisopropanol solution at room temperature. Add 0.84 g of silica airgel powder into hexafluoroisopropanol in batches in a small amount and multiple times, and ultrasonically oscillate for 2 hours until uniformly dispersed to obtain a dispersion of silica airgel;

[0041] 2) PA6 / SiO2 2 Preparation of spinning solution: Weigh 2g of dried PA6 resin and add it to the dispersion of silica airgel, stir magnetically at room temperature for 12 hours until the PA6 resin is completely dissolved, let stand for defoaming, and obtain the content of silica airgel It is a 42wt% electrospinning solution;

[0042] 3) PA6 / SiO2 2 Electrospinning: Use the self-assembled electrospinning nanofiber equipment as the spinning device, and use a 10ml medical syringe to extract the prepared PA6 / SiO 2 Solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com