Method for preparing gelatin/polycaprolactone composite nanometer fiber membrane through electrostatic spinning

A technology of composite nanofibers and polycaprolactone, which is applied in fiber processing, conjugated synthetic polymer artificial filaments, cellulose/protein conjugated artificial filaments, etc., can solve the time-consuming problem of nanofiber membranes (several hours or Longer time, adverse effects on composite nanofiber morphology and other properties, failure to achieve complementary advantages, etc., to achieve the effect of continuous nanofiber industrial production, low cost, and solve the problem of phase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Take 0.5g gelatin and 0.5g polycaprolactone with an electronic analytical balance and dissolve them in 10ml of trifluoroethanol, stir until completely dissolved, and obtain gelatin / polycaprolactone with a concentration of 10% (g / ml) For the spinning solution, add 10 ul of acetic acid to the solution, stir for 10-20 minutes to make the solution change from cloudy to clear, and obtain the gelatin / polycaprolactone spinning solution.

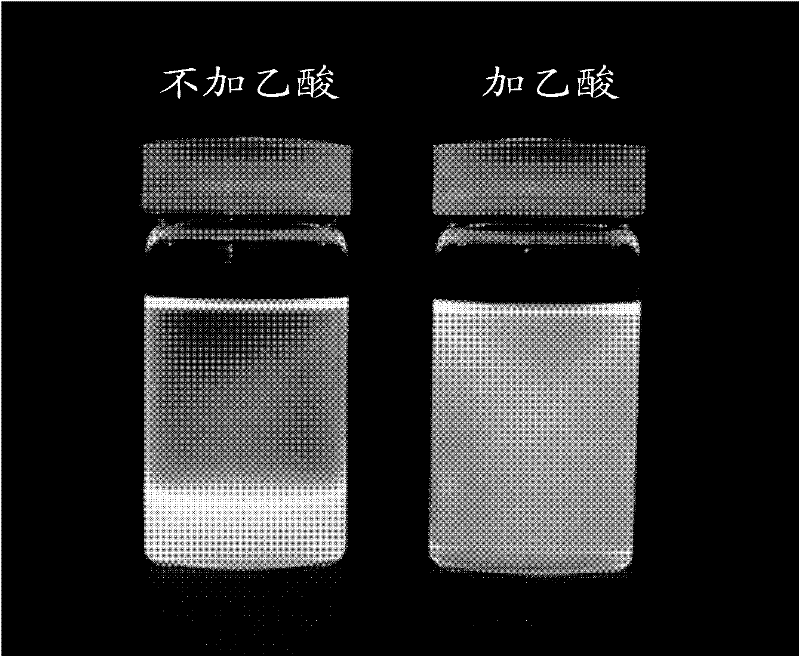

[0030] figure 1 It is a black and white photo of gelatin / polycaprolactone spinning solution without acetic acid and acetic acid added after standing for 12 hours. In the photos, it can be clearly seen that a large amount of precipitation occurred after the spinning solution without acetic acid was left standing.

[0031](2) Select a 10ml syringe and a needle with an inner diameter of 1.2mm to extract the gelatin / polycaprolactone spinning solution and fix it on an electrospinning device for electrospinning. The parameters are: voltage 9kv,...

Embodiment 2

[0034] (1) Take 0.5g gelatin and 0.5g polycaprolactone with an electronic analytical balance and dissolve them in 10ml of trifluoroethanol, stir until completely dissolved, and obtain gelatin / polycaprolactone with a concentration of 10% (g / ml) For the spinning solution, add 20ul of acetic acid to the solution and stir for 10-20min until the solution turns from turbid to clear to obtain a gelatin / polycaprolactone spinning solution.

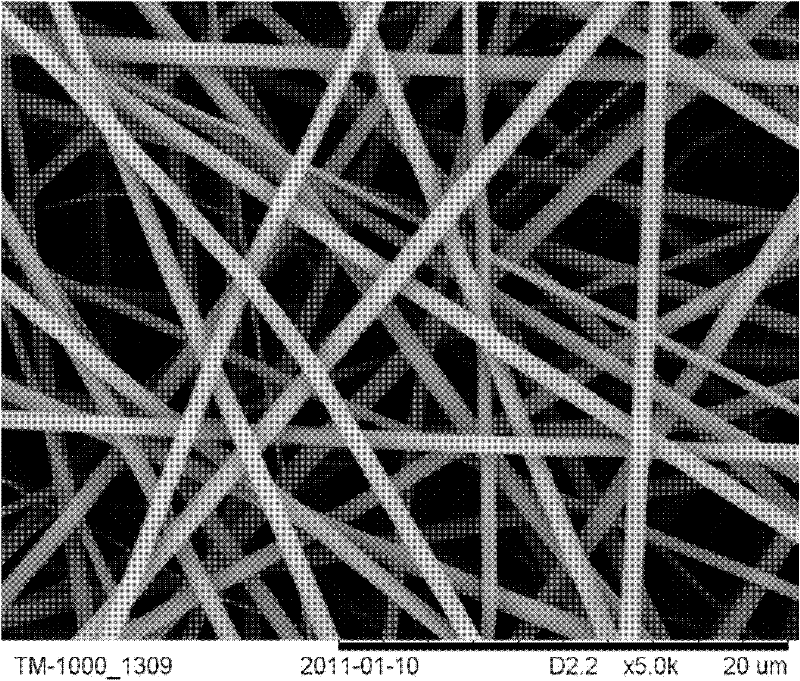

[0035] (2) Choose a 10ml syringe and a needle with an inner diameter of 1.2mm to extract the gelatin / polycaprolactone spinning solution and fix it on the electrospinning device for electrospinning. The electrospinning parameters are: voltage 13kv, acceptance distance 15cm, injection rate 2ml / h, temperature 30°C, relative humidity 50%. Using aluminum foil as a receiving device, spinning for 5 hours to obtain a gelatin / polycaprolactone composite nanofiber membrane. The collected composite fiber membranes were dried in a vacuum oven for 24 h. Figur...

Embodiment 3

[0038] (1) Take 0.5g gelatin and 0.5g polycaprolactone with an electronic analytical balance and dissolve them in 10ml of trifluoroethanol, stir until completely dissolved, and obtain gelatin / polycaprolactone with a concentration of 10% (g / ml) For the spinning solution, add 30ul of acetic acid to the solution and stir for 10-20min until the solution turns from turbid to clear to obtain a gelatin / polycaprolactone spinning solution.

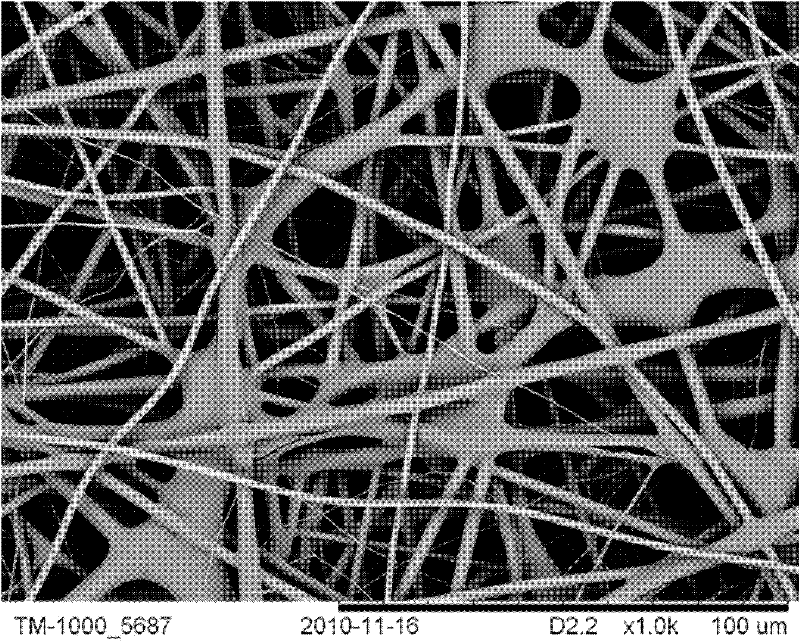

[0039] (2) Choose a 10ml syringe and a needle with an inner diameter of 1.2mm to extract the gelatin / polycaprolactone spinning solution and fix it on the electrospinning device for electrospinning. The electrospinning parameters are: voltage 12kv, acceptance distance 12cm, injection rate 2ml / h, temperature 25°C, relative humidity 40%. Using aluminum foil as a receiving device, spinning for 5 hours to obtain a gelatin / polycaprolactone composite nanofiber membrane. The collected composite fiber membranes were dried in a vacuum oven for 24 h.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com