Thin-long hair fibre an dits production method

A manufacturing method and technology of animal hair, applied in fiber processing, textile and papermaking, yarn and other directions, can solve the problems of increasing fiber length, and achieve the effect of reducing fiber diameter, light weight and high air content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

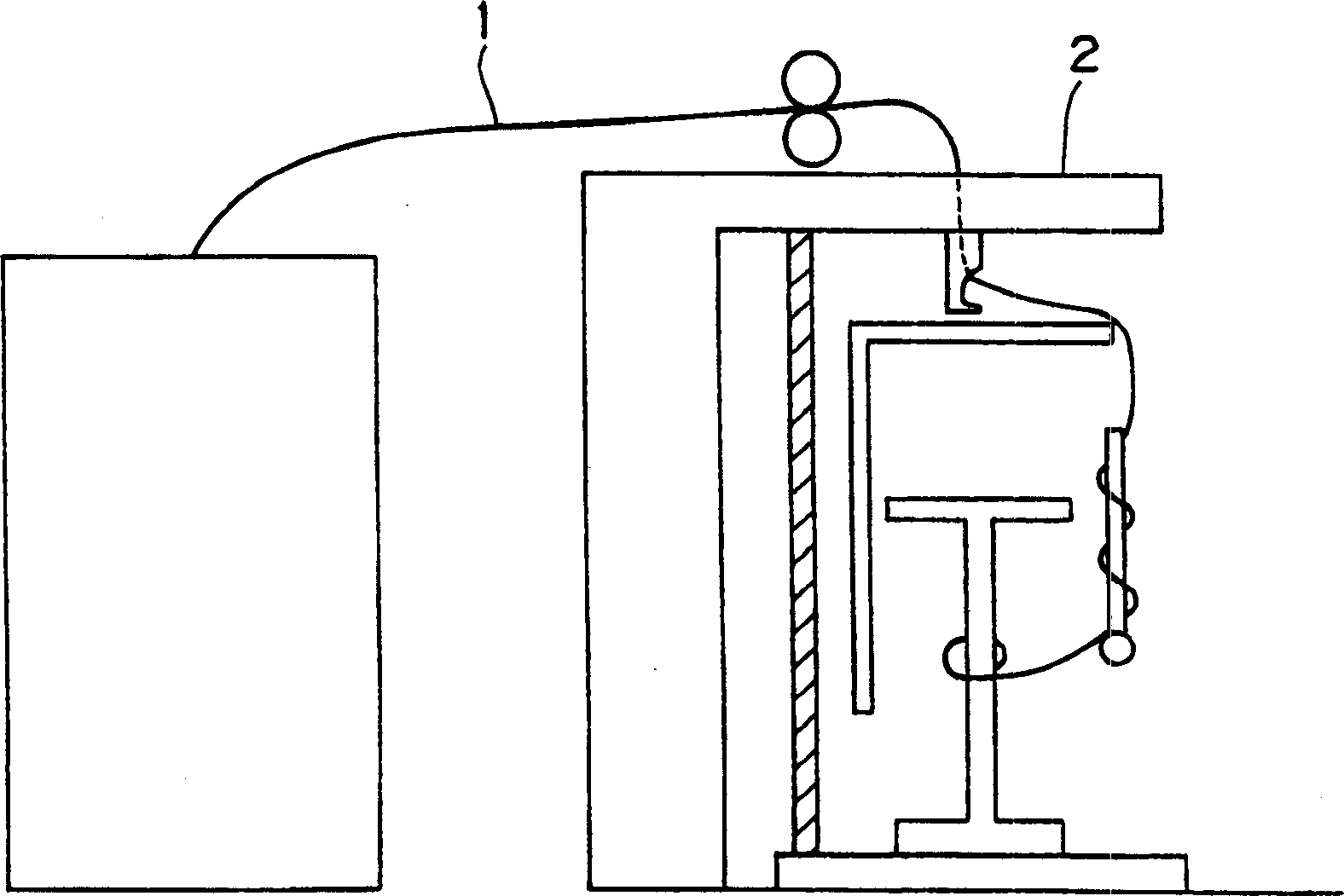

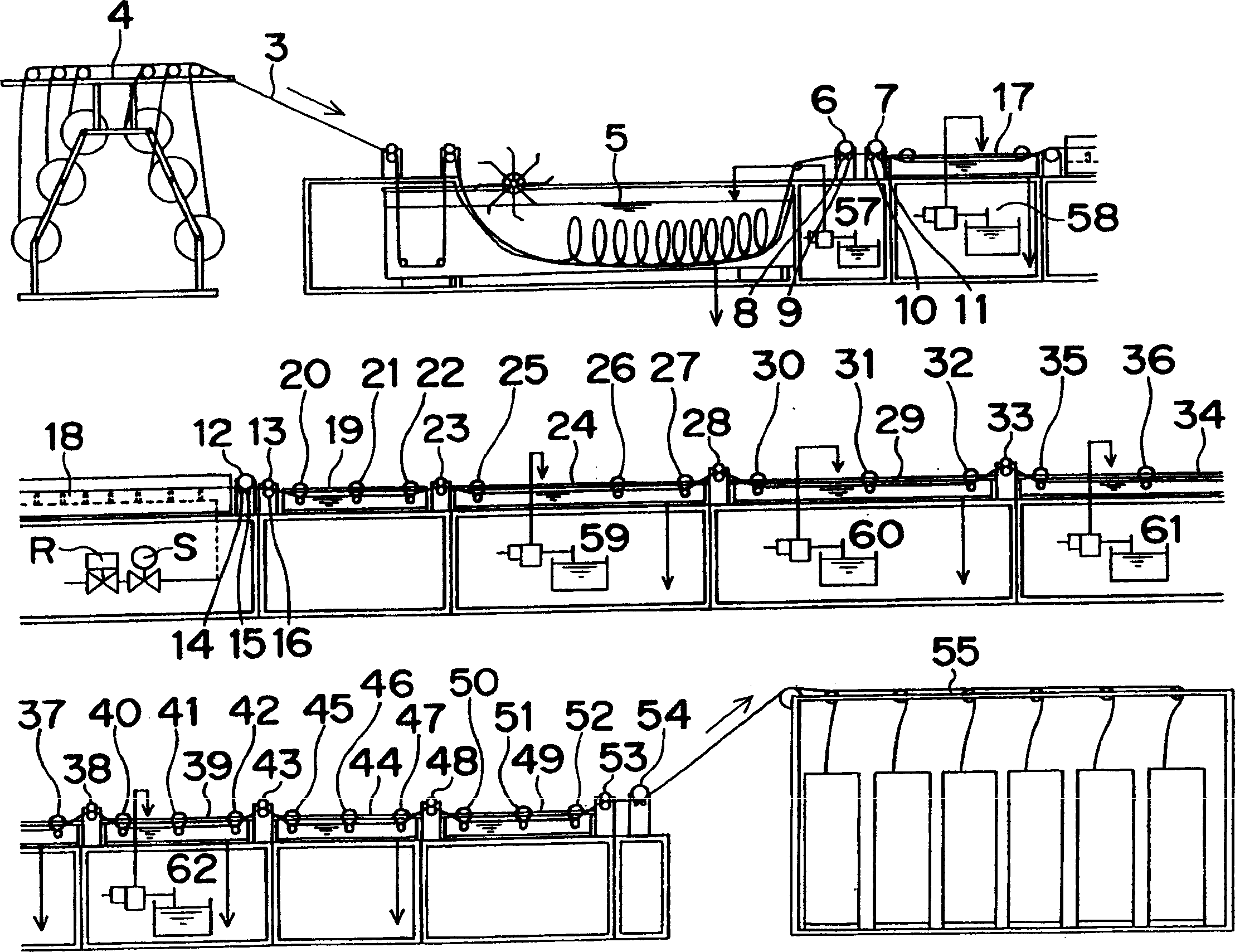

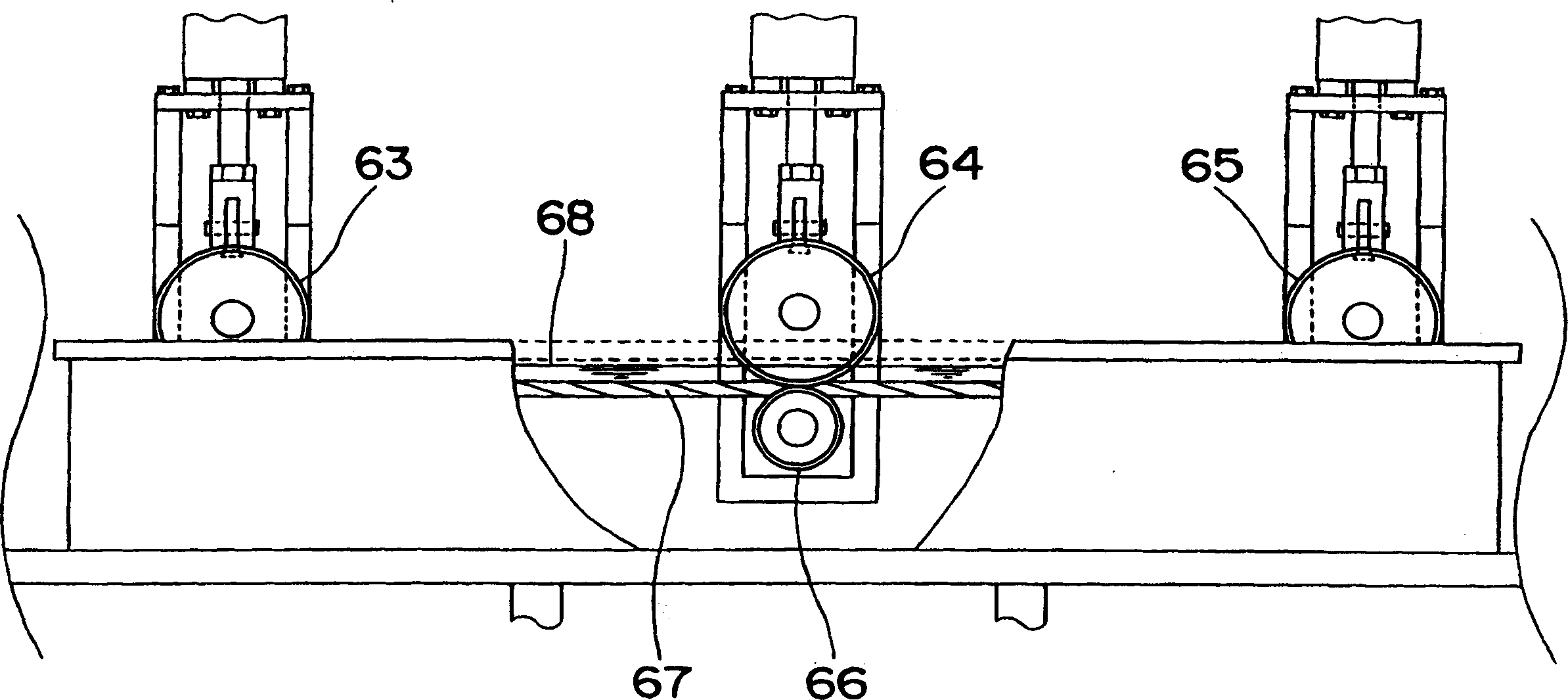

[0116] according to figure 1As shown in the process diagram, the 37g / m merino wool sliver 1 made of an average fiber diameter of 18.7 microns and an average fiber length of 77.2mm (the longest fiber length is 150mm) is twisted to 16 turns with the flyer twister 2 The wool slivers / m were sent to the pretreatment tank 5 at a speed of 1.3m / min, and plasticized and swelled for 30 minutes at 40°C in the treatment solution of the following composition.

[0117] Sodium bisulfite 30g / l

[0118] Monoethanolamine 2g / l

[0119] Caustic soda about 10g / l (adjust the pH of the treatment solution to 8.0)

[0120] Then, send this sliver to the reduction tank 17 that has added the solution with the same composition as the pretreatment tank liquid, and carry out plasticization and swelling under the conditions of 80°C and 30 seconds, and then use steam 18 to carry out 95°C, 70 seconds of steam treatment. Simultaneously, the superficial speed of roller group 12,13 is accelerated ...

Embodiment 2

[0140] A 37 g / m wool sliver with an average fiber diameter of 27.0 microns and an average fiber length of 70.0 mm is applied with a flyer twister 2 to twist at 16 revolutions / m. Except for the following processing conditions, the others are the same as in Example 1. Processing conditions are processed.

[0141] [Conditions different from Example 1]

[0142] i) Composition, treatment temperature and time of the plasticizing and swelling pretreatment tank 5:

[0143] Sodium bicarbonate 1.5g / l

[0144] Sodium carbonate 0.15g / l

[0145] Immersion conditions 60°C, 10 minutes

[0146] ii) Stretch ratio: 1.7 times (actual stretch ratio: 1.25 times)

[0147] iii) Instead of passing through the reduction treatment tank 17 and omitting the oxidation treatment with hydrogen peroxide, it is replaced with hot water at 80°C (treatment tanks 24, 29, 34).

[0148] iv) Treat tank 39 with acetic acid instead of formic acid, and perform neutralization treatment at pH 4.5.

[01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com