Nano spider web/beaded fiber composite air filter membrane and preparation method thereof

An air filtration and fiber composite technology, which is applied in separation methods, dispersed particle filtration, chemical instruments and methods, etc., can solve the problems of high filtration efficiency and low filtration resistance, and achieve high filtration efficiency, low resistance pressure drop, and flexible structure Regulatory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

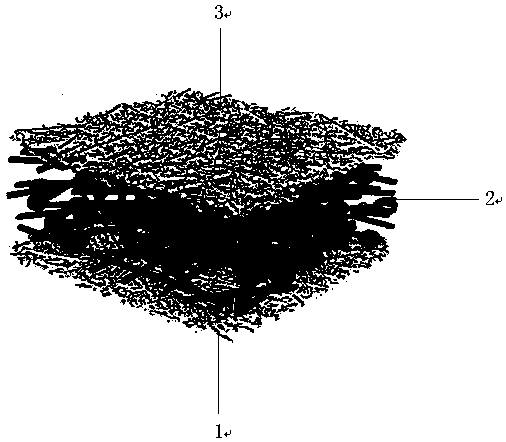

[0033] A preparation method of nano spider web / beaded fiber composite air filter membrane, the specific preparation process is as follows:

[0034] (1) Add 0.15g polyamide 6 to 0.83g formic acid solvent at room temperature, then add 0.02g sodium chloride, stir continuously with a magnetic stirrer until fully dissolved, and obtain a polyamide containing sodium chloride with a mass fraction of 15% 6 Spinning solution; under the conditions of spinning voltage 20kV, receiving distance 15cm, spinning speed 0.3mL / h, temperature 22°C, relative humidity 40%, carry out electrostatic spraying, which will contain two-dimensional network fibers and one-dimensional The polyamide 6 nanometer spider web of the nanofiber is deposited on the aluminum foil surface of the receiving drum to obtain the polyamide 6 nanometer spider web receiving layer.

[0035](2) Add 0.64g of polyamide 6 to 7.36g of formic acid solvent at room temperature, stir continuously with a magnetic stirrer until fully diss...

Embodiment 2

[0041] A preparation method of nano spider web / beaded fiber composite air filter membrane, the specific preparation process is as follows:

[0042] (1) Add 0.3g of polyamide 66 to 1.17g of formic acid solvent at room temperature, then add 0.03g of calcium chloride, stir continuously with a magnetic stirrer until fully dissolved, and obtain a polyamide containing calcium chloride with a mass fraction of 20% 66 spinning solution; under the conditions of spinning voltage 30kV, receiving distance 15cm, spinning speed 0.5mL / h, temperature 25 ℃, relative humidity 25%, carry out electrostatic spraying, will contain two-dimensional network fibers and one-dimensional The polyamide 66 nanometer spider web of the nanofiber is deposited on the aluminum foil surface of the receiving drum to obtain the polyamide 66 nanometer spider web receiving layer.

[0043] (2) Add 0.7g of polyamide 66 to 6.3g of formic acid solvent at room temperature, stir continuously with a magnetic stirrer until fu...

Embodiment 3

[0048] A preparation method of nano spider web / beaded fiber composite air filter membrane, the specific preparation process is as follows:

[0049] (1) Add 0.24g of polyacrylonitrile to 1.73g of N-N dimethylformamide solvent at room temperature, then add 0.03g of potassium chloride, stir continuously with a magnetic stirrer until fully dissolved, and obtain a 12% mass fraction containing Potassium chloride polyacrylonitrile spinning solution; under the conditions of spinning voltage 30kV, receiving distance 20cm, spinning speed 1mL / h, temperature 25°C, and relative humidity 45%, carry out electrostatic spraying, and the two-dimensional net The polyacrylonitrile nano-spider web of the shape fiber and the one-dimensional nano-fiber is deposited on the surface of the aluminum foil of the receiving drum to obtain the polyacrylonitrile nano-spider web receiving layer.

[0050] (2) Add 0.36g of polyacrylonitrile to 5.64g of N-N dimethylformamide solvent at room temperature, stir con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com