Discontinuous multi-strand spiral flow baffle plate shell-and-tube heat exchanger

A shell-and-tube heat exchanger and baffle technology, which is applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc., can solve the problem of rising pressure drop of shell side resistance, large pressure drop, and reduced heat transfer efficiency. and other problems, to achieve the effect of reducing fluid resistance pressure drop, reducing manufacturing cost, and high membrane heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

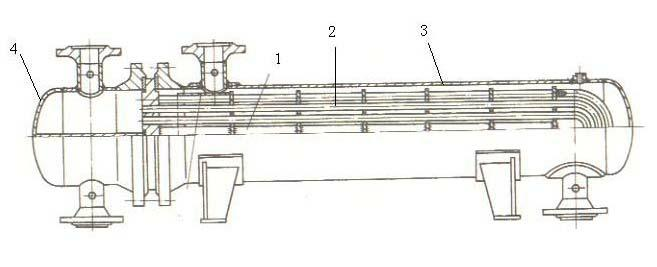

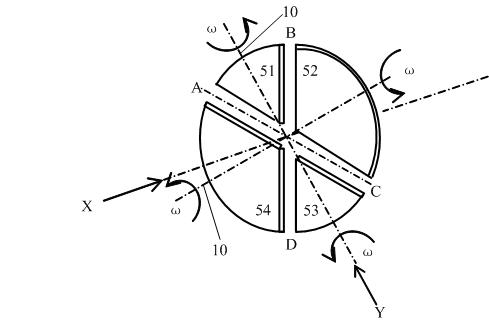

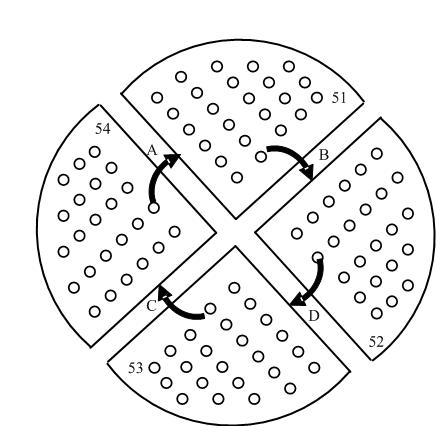

[0058] One of the specific implementations of a discontinuous multi-strand spiral flow baffle shell-and-tube heat exchanger of the present invention, refer to figure 1 As shown, it includes a tube bundle 2, a tube shell 3 and a tube box 4. The tube bundle 2 includes a heat exchange tube 1, a spiral flow baffle, a distance tube (not shown in the figure) and a tube sheet 6. The heat exchange tube 1 is The rows pass through the spiral flow baffles, and the two ends of the heat exchange tubes 1 penetrate into the tube holes of the tube sheet 6 and are connected with the tube sheet 6. The above technical features are the same as those of the spiral flow baffle tubes in the prior art. Shell heat exchangers have the same structure. The shell-and-tube heat exchanger also has other basic structures of the shell-and-tube heat exchanger in the prior art. The improvement of the present invention is that, with reference to Figure 7 As shown, the helical flow baffles include two or more ...

Embodiment 2

[0076] The second specific embodiment of a discontinuous multi-strand spiral flow baffle shell-and-tube heat exchanger of the present invention, the main technical solution of this embodiment is the same as that of embodiment 1, and the unexplained features in this embodiment, The explanation in Embodiment 1 is adopted, and details are not repeated here. The difference between this embodiment and Embodiment 1 is that an opening interval is provided between two adjacent fan-shaped baffles in the fan-shaped baffle group along the circumferential direction of the tube bundle . For the same tube bundle, the opening spacing in each group of fan-shaped baffles Can be set the same, or adjusted to , ... etc. different opening intervals . For different tube bundles, the opening spacing in each tube bundle The settings may be the same or different.

[0077] Specifically, the opening intervals in each fan-shaped baffle group set on the same line. And the straight line is ...

Embodiment 3

[0085] The third embodiment of a discontinuous multi-strand spiral flow baffle shell-and-tube heat exchanger of the present invention is as follows: Figure 7 As shown, the main technical solutions of this embodiment are the same as those of Embodiment 2, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and Embodiment 2 is that there are six groups of fan-shaped baffles in this embodiment, each group of fan-shaped baffles includes three fan-shaped baffles, and the two groups of fan-shaped baffles Take a solid line B1-B2 and a dotted line A1-A2 with arrows on the flow plate group as an example, specifically marking the two helical flow path trajectories of the shell-side fluid of the tube bundle, in which the B1 section and A1 section are the main helical flow , Sections B2 and A2 are very short, or almost non-existent direct currents along the axial direction. The overall heli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com