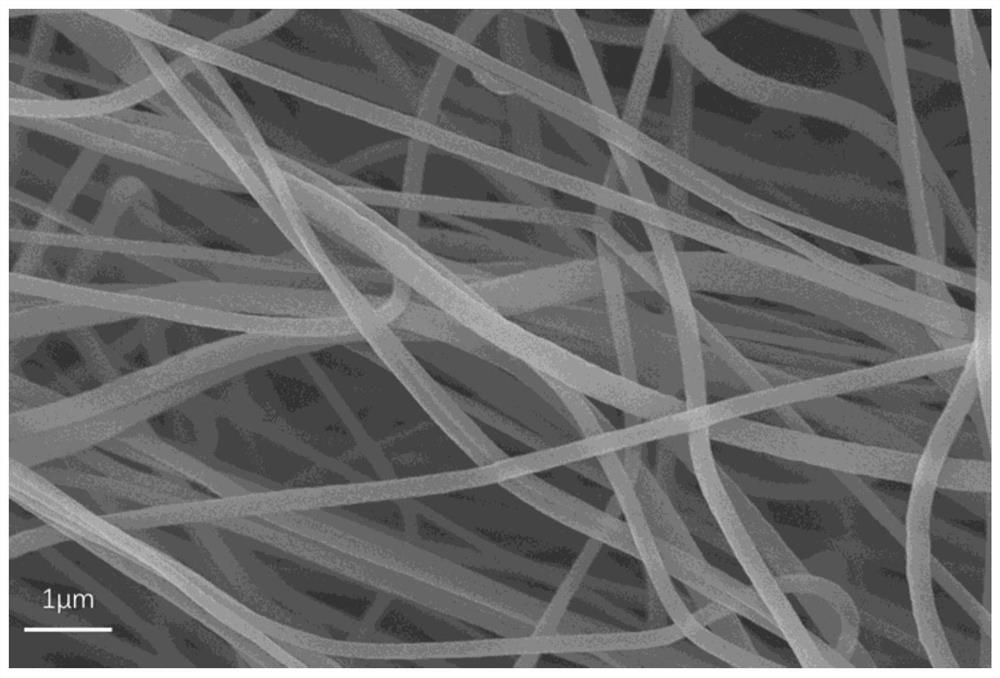

Electret nanofiber high-efficiency filter material and preparation method thereof

A high-efficiency filtration and nanofiber technology, applied in separation methods, filtration separation, fiber treatment, etc., can solve the problems of unstable electret performance and low filtration efficiency of fine particles, and achieve low production costs, good air permeability, The effect of improving interception efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 of the present embodiment provides an electret nanofiber high efficiency filter material in a preferred embodiment, which is prepared by a spinning liquid loaded on a PP meltblown nonwoven support material by electrospinning method. Wherein, the spinning liquid in this embodiment comprises the following components by weight:

[0035] 8 parts polyacrylonitrile (PAN);

[0036] 8 parts linear polarizable polybenzoate containing azo side groups; and

[0037] 84 parts N, N-dimethylformamide solvent.

[0038] The present embodiment 1 also provides a method for preparing the above material, as follows:

[0039] (1) Weigh 8 parts of polyacrylonitrile (PAN) and 8 parts of linear polarizable polybenzoate containing azo side groups added to a container containing 84 parts of N, N-dimethylformamide solvent, placed in a 60 ° C water bath heated and stirred until dissolved, configured into a uniform transparent solution (i.e., spinning liquid).

[0040](2) Set the electrospinni...

Embodiment 2

[0053] Example 2 of the present embodiment provides another preferred embodiment of a station pole nanofiber efficient filter material, which is prepared by a spinning liquid loaded on a PP spunbond nonwoven support material. The embodiment of the spinning liquid comprises the following components by weight:

[0054] 15 parts polystyrene (PS);

[0055] 15 parts linearly polarizable polystyrene containing azobenzene side groups; and

[0056] 70 parts N, N-dimethylacetamide solvent.

[0057] The present embodiment also provides a method for preparing the above material, as follows:

[0058] (1) Weigh 15 parts of polystyrene (PS) and 15 parts of linear polarizable polystyrene containing azobenzene side group added to a container containing 70 parts of N, N- dimethylacetamide solvent, placed in a 60 ° C water bath heating and stirring until dissolved, configured into a uniform and transparent spinning liquid.

[0059] (2) Set the electrospinning process parameters: the flow rate is 2m...

Embodiment 3

[0070]The present embodiment provides another preferred embodiment of the electret nanofiber efficient filter material, which is prepared by the spinning liquid load on the PP meltblown non-woven fabric support material, the spinning liquid comprises the following components by weight:

[0071] 10 parts polymethyl methacrylate (PMMA);

[0072] 15 parts linearly polarizable polymethyl methacrylate containing azobenzene lateral group; and

[0073] 75 parts N,N-dimethylformamide solvent.

[0074] The present embodiment also provides a method for preparing the above material, as follows:

[0075] (1) Weigh 10 parts of polymethyl methacrylate (PMMA) and 15 parts of linearly polarizable polymethyl methacrylate containing azo benzene side group added to a container containing 75 parts of N, N- dimethylformamide solvent, placed in a 60 ° C water bath heating and stirring until dissolved, configured into a uniform transparent solution (i.e., spinning liquid).

[0076] (2) Set the electrosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com