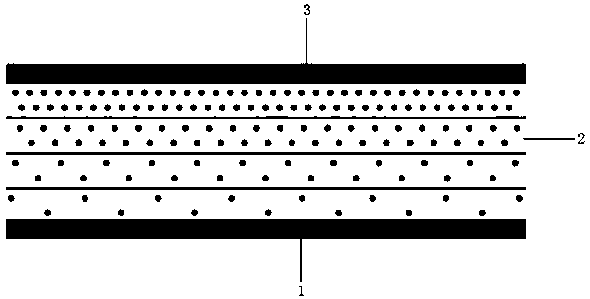

A microbead/nanofiber composite air filter material with gradient structure and preparation method thereof

An air filter material and nanofiber technology, which is applied in the field of electrospinning nanofiber air filter material preparation, can solve the problems of easy particle agglomeration, limited application scope, reduced material resistance and pressure drop, etc., so as to improve filtration efficiency and dust holding capacity. , to avoid the rapid increase in resistance and reduce the effect of filtering resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of a microbead / nanofiber composite air filter material with a gradient structure, the specific steps are:

[0029] A certain amount of dry polyamide 6 particles were weighed and dissolved in formic acid with an electronic balance, and stirred continuously for 10 hours with a magnetic stirrer to obtain a homogeneous solution of polyamide 6 with a mass fraction of 22%, which was used as a method for spinning polyamide 6 nanofibers. Spinning solution; meanwhile, dissolve an appropriate amount of dry polyamide 6 particles in formic acid, and place it on a magnetic stirrer to stir for 10 hours to obtain a homogeneous solution of polyamide 6 with a mass fraction of 10%, which is used as a spinning polyamide 6 solution. Spinning solution of amide 6 microbeads; when preparing the first layer of microbeads / nanofiber layer, inject 2g of a mass fraction of 22% polyamide 6 solution in one syringe, and inject 0.2g of a mass fraction of 10 in another syringe % poly...

Embodiment 2

[0031] A preparation method of a microbead / nanofiber composite air filter material with a gradient structure, the specific steps are:

[0032] A certain amount of dry polyamide 6 particles were weighed and dissolved in formic acid with an electronic balance, and stirred continuously for 8 hours with a magnetic stirrer to obtain a homogeneous solution of polyamide 6 with a mass fraction of 20%, which was used as a starting point for spinning polyamide 6 nanofibers. Spinning solution; at the same time, an appropriate amount of dry polyamide 6 particles were dissolved in formic acid, and placed on a magnetic stirrer to stir for 8 hours to obtain a homogeneous solution of polyamide 6 with a mass fraction of 8%, which was used as a spinning polyamide 6 solution. Spinning solution of amide 6 microbeads; when preparing the first layer of microbeads / nanofiber layer, inject 1g of a mass fraction of 20% polyamide 6 solution in one syringe, and inject 0.1g of a mass fraction of 8 in anoth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com