Composite filtering material and preparation method thereof

A composite filtration and filtration layer technology, applied in filtration and separation, membrane filters, separation methods, etc., can solve problems such as unfavorable centrifugal spinning industrialization, discontinuous fiber filaments, etc., to improve the chance of collision and adhesion, increase the The effect of large specific surface area and nanopore volume, reducing resistance pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

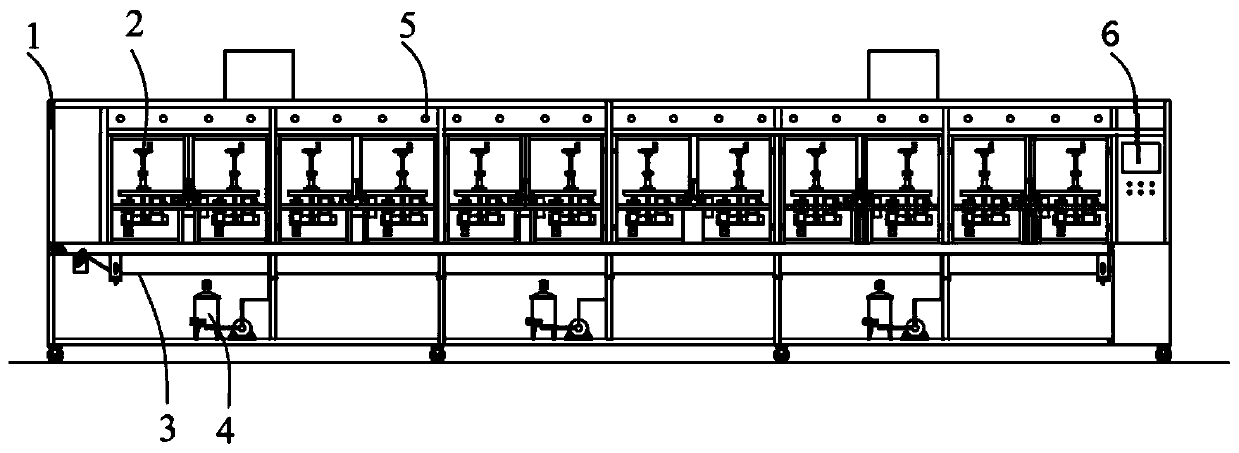

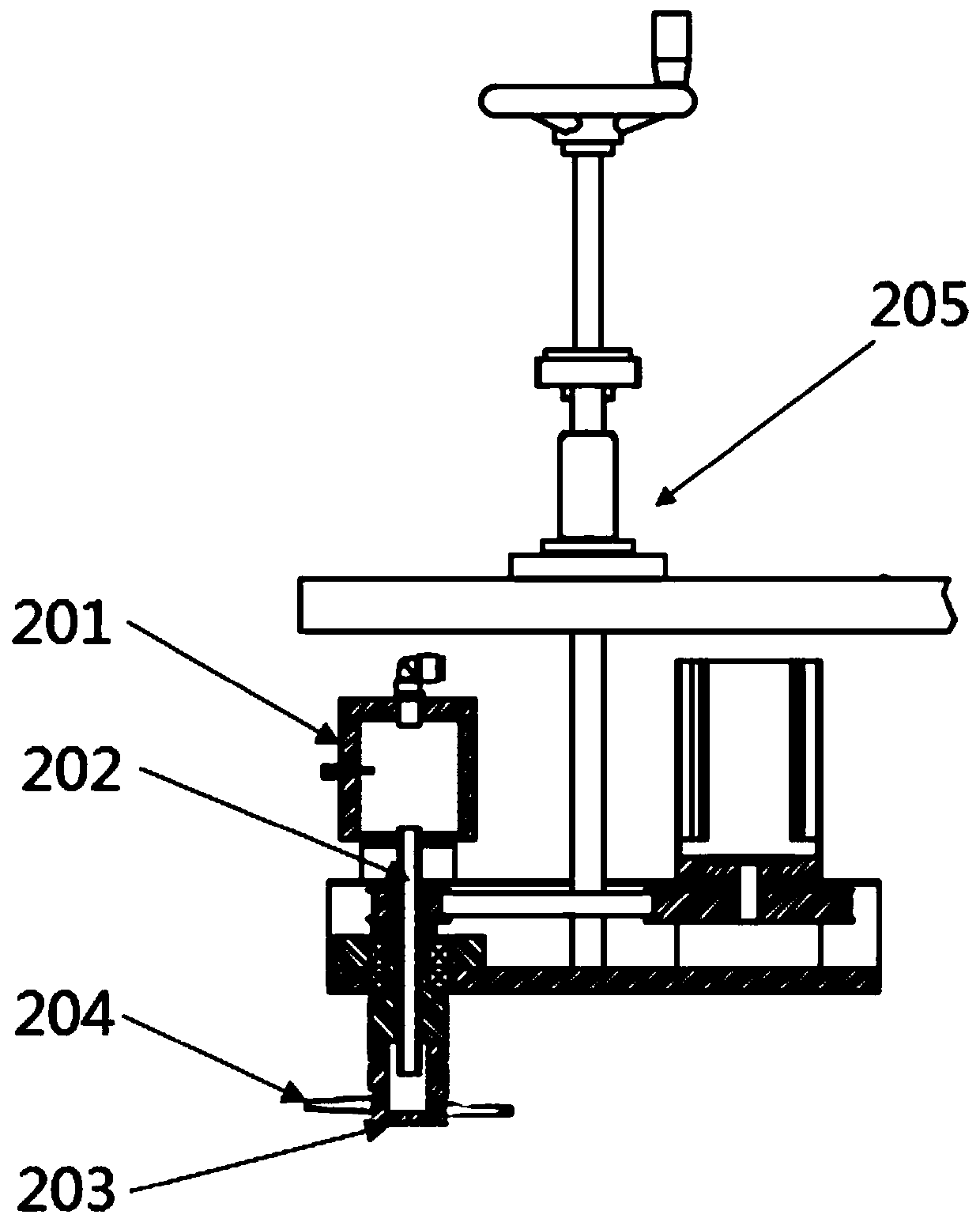

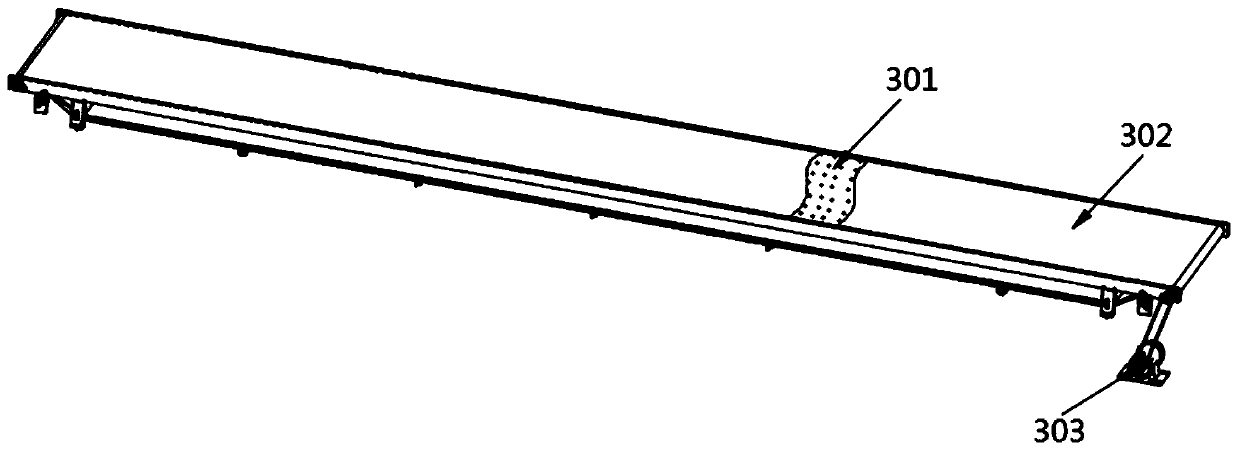

[0046] see Figure 4-6 As shown, the invention provides a kind of preparation method of composite filter material, comprises the steps:

[0047] S1. Prepare a first polymer spinning solution with a predetermined concentration, pour it into a plane receiving centrifugal spinning device, and perform centrifugal spinning, and collect it in a collecting device to obtain a primary filter layer of non-woven fabric;

[0048] S2. Prepare a mixed organic solvent of dichloromethane / N,N-dimethylacetamide in a predetermined mass ratio, and then add titanium dioxide nanoparticles and second polymer particles respectively for stirring and ultrasonic treatment to obtain a polymer / titanium dioxide / organic solvent mixed spinning silk liquid; finally, the electrospinning process is used to prepare porous structure micro-nano fibers, which are collected and deposited on the surface of the non-woven primary filter layer to obtain the porous micro-nano fiber medium-effect filter layer;

[0049] S...

Embodiment 1

[0054] A preparation method of a composite filter material, comprising the steps of:

[0055] S1. Dissolve polyimide polymer particles in N,N-dimethylacetamide, prepare a polyimide spinning solution with a mass fraction of 25 wt%, inject it into a plane receiving centrifugal spinning device, and perform centrifugal spinning Silk, collected by the collection device to obtain the primary filter layer of non-woven fabric; wherein, during the centrifugal spinning process, the spinneret aperture is 0.41mm, the collection distance is 10cm, the spinning temperature is 80°C, and the spinning speed is 8000r / min.

[0056] S2. Prepare a mixed organic solvent of dichloromethane / N,N-dimethylacetamide (DCM / DMAC) with a mass ratio of 10:1, add titanium dioxide particles, stir thoroughly at room temperature with a constant temperature magnetic stirrer, and then perform ultrasonic treatment ; Then add polystyrene particles, fully stir until completely dissolved, and then ultrasonically treat, ...

Embodiment 2-10

[0063] The difference from Example 1 is: the mass fraction of polystyrene and titanium dioxide, the mass ratio of dichloromethane / N,N-dimethylacetamide (DCM / DMAC) and the difference in relative humidity, other steps are basically the same, I won't repeat them here.

[0064] Table 1 is the setting of the mass fraction of polystyrene and titanium dioxide, methylene chloride / N,N-dimethylacetamide (DCM / DMAC) mass ratio and relative humidity in Examples 1-10

[0065] Example polystyrene Titanium dioxide DCM / DMAC Relative humidity Example 1 10wt% 1.0wt% 10:1 45% Example 2 5wt% 1.0wt% 10:1 45% Example 3 20wt% 1.0wt% 10:1 45% Example 4 7wt% 0.5wt% 10:1 45% Example 5 7wt% 1.5wt% 10:1 45% Example 6 7wt% 2.0wt% 10:1 45% Example 7 7wt% 1.0wt% 8:1 45% Example 8 7wt% 1.0wt% 12:1 45% Example 9 7wt% 1.0wt% 10:1 30% Example 10 7wt% 1.0wt% 10:1 55%

[0066] In Exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com