Novel blast furnace gas dechlorination and hydrolysis conversion integrated tower

A technology of blast furnace gas and hydrolysis tower, which is applied in the field of blast furnace gas tower, and can solve problems such as difficult dechlorination and hydrolysis catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

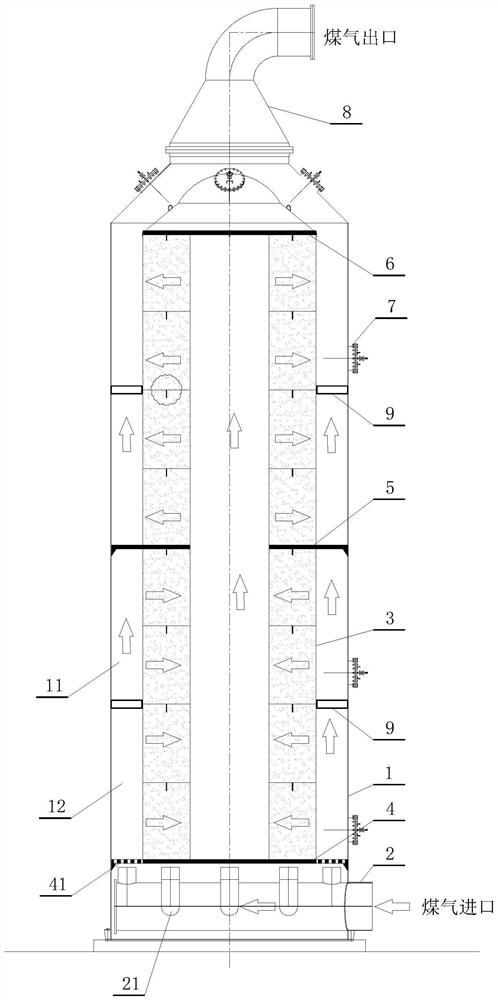

[0029] from figure 1 It can be seen that a novel blast furnace gas dechlorination and hydrolysis conversion integrated tower in this embodiment includes a tower body shell 1, the bottom of the tower body shell 1 is provided with an inlet gas distribution pipe 2, and the bottom of the tower body shell 1 A lower bracket plate 4 is provided, and flow guide holes 41 are spaced apart on the surface of the lower bracket plate 4 .

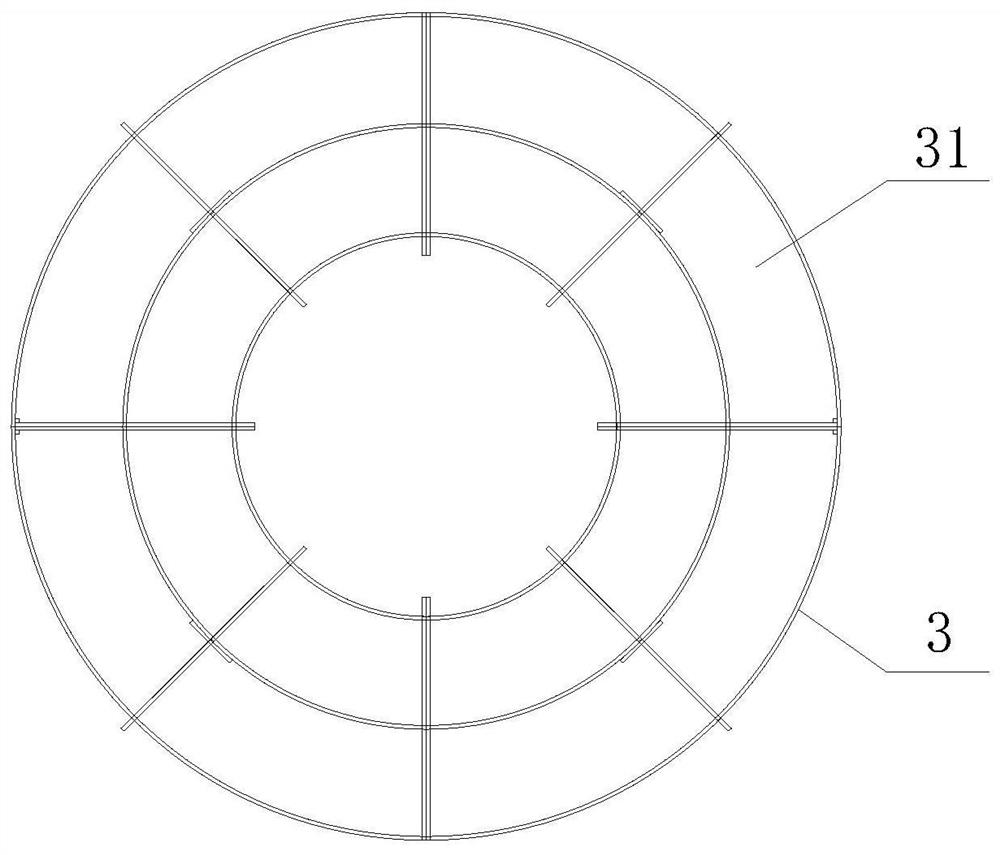

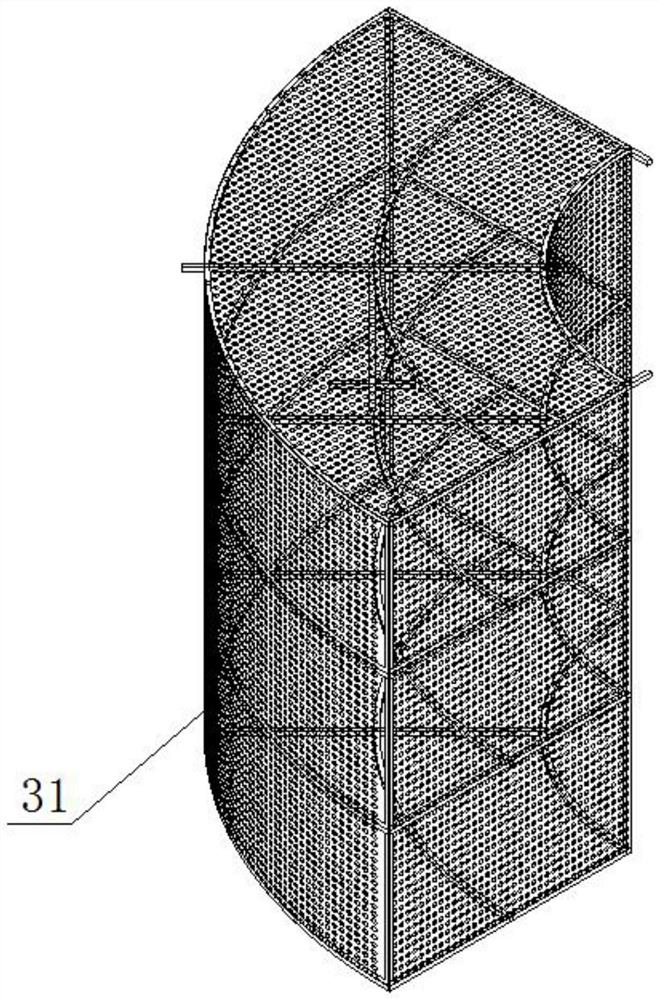

[0030] The middle part of the tower body shell 1 is provided with a middle bracket plate 5, and the middle bracket plate 5 divides the inside of the tower body shell 1 into two parts, which are respectively a hydrolysis tower body 11 and a dechlorination tower body 12, and the tower body shell Body 1 is made of Q345B material. The diameter and wall thickness of the tower body are calculated according to the amount of gas to be processed. The upper tower is a hydrolysis tower, and the lower tower is a dechlorination tower. Both the hydrolysis tower body 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com