A kind of air filter material capable of releasing negative ions and preparation method thereof

An air filter material and negative ion technology, which is applied in the field of nanofibers, can solve the problems of poor bonding fastness of nanofiber layers, poor purification effect persistence, and low negative ion release, and achieve strong bonding fastness, enhanced bonding fastness, negative ion High release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

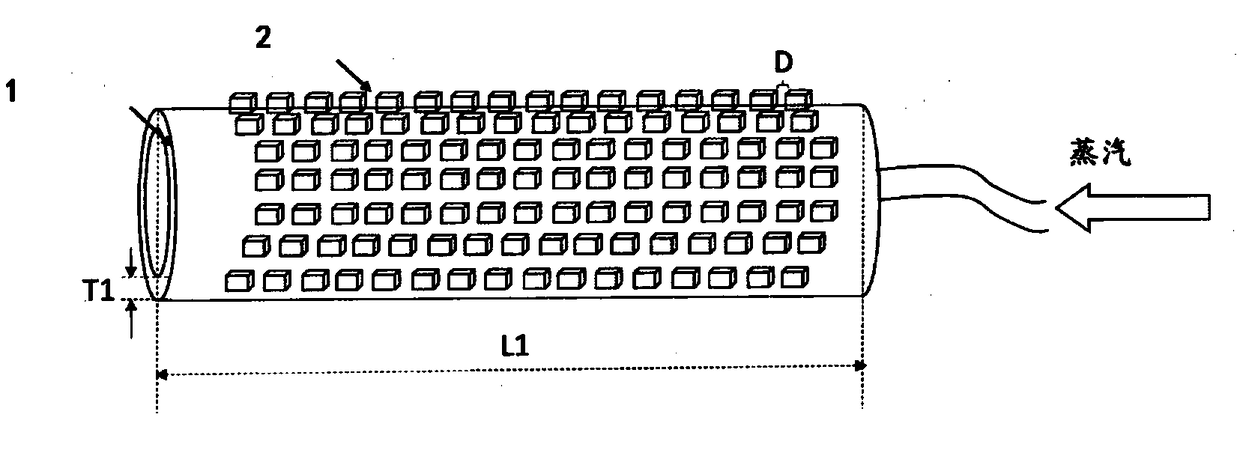

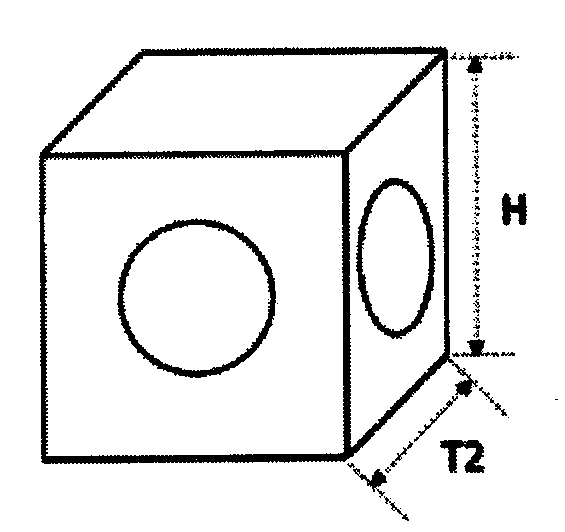

[0030] Such as figure 1 As shown, an electrospinning receiving device includes a drum 1. The surface of the drum 1 is provided with a plurality of hollow protrusions 2, and one side of the protrusions 2 is in contact with the drum 1. The contact surface of 1 can be connected to the inside of the drum 1. The opposite sides of this surface are closed. Except for the two sides, the other surfaces are provided with holes. The inside of the drum 1 is a hollow structure, one end is connected with a high-temperature steam generator and the other end is closed. The steam is discharged from the holes of the protrusion 2, which can etch the surface of the substrate in contact with it, and increase the surface roughness of the substrate. The discharge speed depends on the cross-sectional area of the roller, the area of the small hole and the feeding speed.

[0031] The cross section of the roller 1 is circular and the cross-sectional area is 100 cm 2 , The length L1 is 30cm, and the mate...

Embodiment 2

[0033] Similar to the electrospinning receiving device of embodiment 1, the difference is: the cross section of the drum 1 is circular, and the cross-sectional area is 200 cm 2 , The length L1 is 40cm, and the material is copper; the wall thickness T1 of the drum is 4cm; the protrusions 2 are regularly arranged on the surface of the drum, and the shape of the protrusions is triangular prism, and the material is the same as that of the drum; The height H of 2 is 0.6mm, and the cross-sectional area is 0.5mm 2 , The thickness T2 is 0.1mm, and the distance D between two adjacent protrusions on the roller is 0.55mm. The shape of the hole is square with an area of 0.08mm 2 .

Embodiment 3

[0035] Similar to the electrospinning receiving device of embodiment 1, the difference is that: the cross section of the drum 1 is circular, and the cross-sectional area is 300 cm 2 , The length L1 is 60cm, and the material is aluminum; the wall thickness T1 of the drum is 6cm; the protrusions 2 are regularly arranged on the surface of the drum, and the shape of the protrusions is a triangular prism, and the material is the same as that of the drum; The height H of 2 is 0.7mm, and the cross-sectional area is 1mm 2 , The thickness T2 is 0.15mm, and the distance D between two adjacent protrusions on the roller is 0.6mm. The shape of the hole is square and the area is 0.7mm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com