Three-dimensional zigzag nanofiber compound window screen and electrostatic spinning method thereof

A nanofiber and electrospinning technology, which is applied in fiber processing, spinning solution preparation, textiles and papermaking, etc., can solve the problems of large resistance pressure drop and low filtration efficiency of filter materials, and achieve low resistance pressure and good fiber structure Controllability, effect of reducing resistance pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

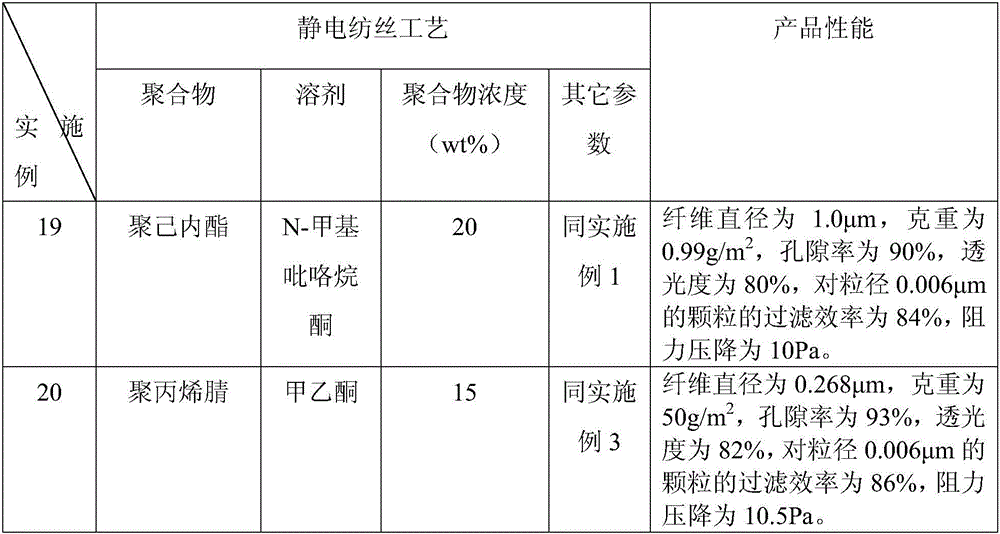

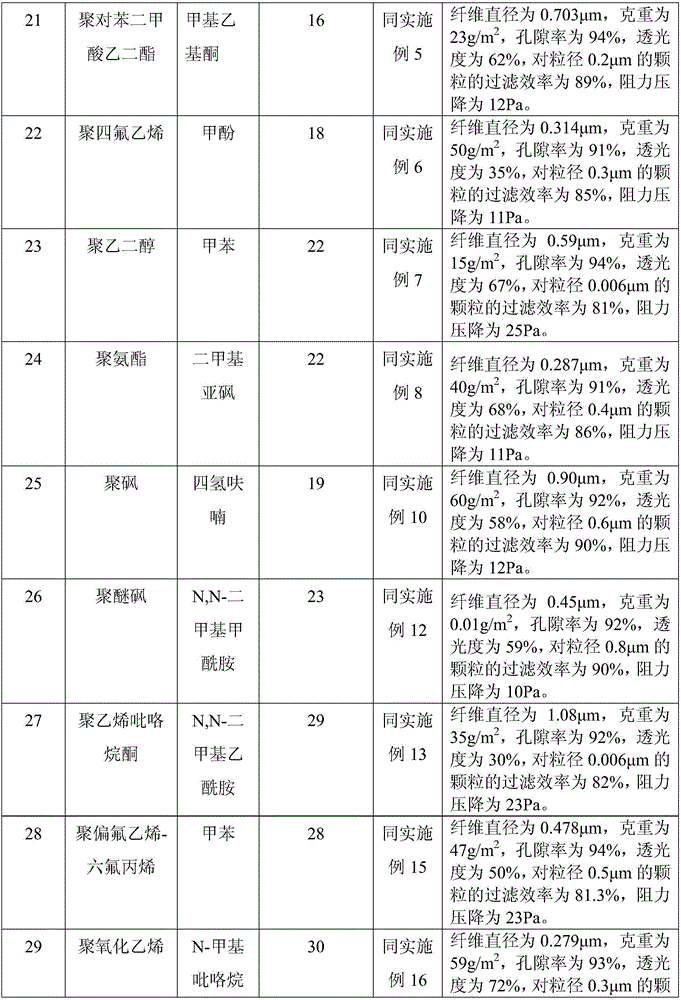

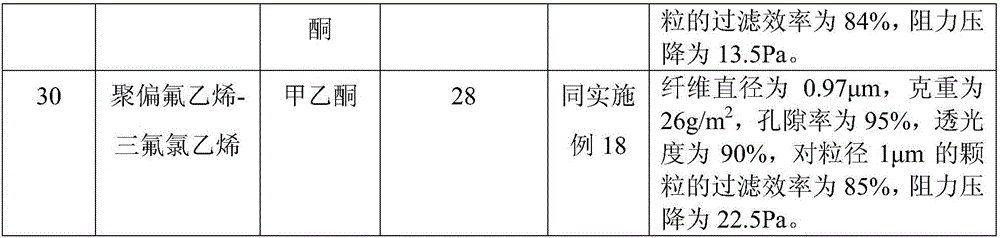

Examples

Embodiment 1

[0030] An electrospinning method of a three-dimensional tortuous nanofiber composite window screen, the specific spinning process is as follows:

[0031] 1) dissolving the fluorinated ethylene propylene copolymer in formic acid to form a spinning solution with a concentration of 25 wt %;

[0032] 2) The receiving surface is selected as the receiving surface of the window screen composite removable three-dimensional zigzag shape template; the removable three-dimensional zigzag shape template is made of hot-melt material, the hot-melt material is gelatin, and the thickness is 0.1mm; the material of the window screen is nylon, and the window screen is made of nylon. The fiber diameter is 50 μm, the pore size is 500 μm, and each zigzag unit of the removable three-dimensional zigzag shape template has a triangular bending mode, the triangular folding height h=5mm, folding width w=57mm, folding angle α=5°, each zigzag unit As a group, the number of groups in the spinning unit is 3, ...

Embodiment 2

[0037] An electrospinning method of a three-dimensional tortuous nanofiber composite window screen, the specific spinning process is as follows:

[0038] 1) dissolving polyperfluoroethylene propylene in tetrahydrofuran to form a spinning solution with a concentration of 20wt%;

[0039] 2) The receiving surface is selected as the receiving surface of the window screen composite removable three-dimensional zigzag shape template; the removable three-dimensional zigzag shape template is made of hot-melt material, the hot-melt material is agarose gel, and the thickness is 0.5mm; the window screen is made of glass fiber, The diameter of the fiber in the screen is 50 μm, the aperture size is 490 μm, and the bending mode of each bending unit of the removable three-dimensional bending shape template is a triangle, the folding height of the triangle is h=40mm, the folding width w is 40mm, and the folding angle α=45°, each The zigzag unit is a group, the number of groups in the spinning ...

Embodiment 3

[0044] An electrospinning method of a three-dimensional tortuous nanofiber composite window screen, the specific spinning process is as follows:

[0045] 1) dissolving a mixture of fluorinated ethylene propylene copolymer and polyperfluoroethylene propylene with a mass ratio of 1:1 in N,N-dimethylformamide to form a spinning solution with a concentration of 20 wt %;

[0046] 2) The receiving surface is selected as the receiving surface of the window screen composite removable three-dimensional zigzag shape template; the removable three-dimensional zigzag shape template is made of hot-melt material, the hot-melt material is gelatin, and the thickness is 0.8mm; the material of the window screen is nylon, and the window screen is made of nylon. The fiber diameter is 48 μm, the pore size is 280 μm, the bending mode of each bending unit of the removable three-dimensional bending shape template is trapezoidal, the folding height of the trapezoid is h=5mm, the folding width w is 59mm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com