Micron fiber three-dimensional framework/polymer nanofiber composite filter material and preparation method thereof

A nanofiber, three-dimensional skeleton technology, applied in the field of textile materials, can solve the problems of complex preparation process and difficult control of material structure, and achieve the effects of easy availability of raw materials, low cost, and good structure controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

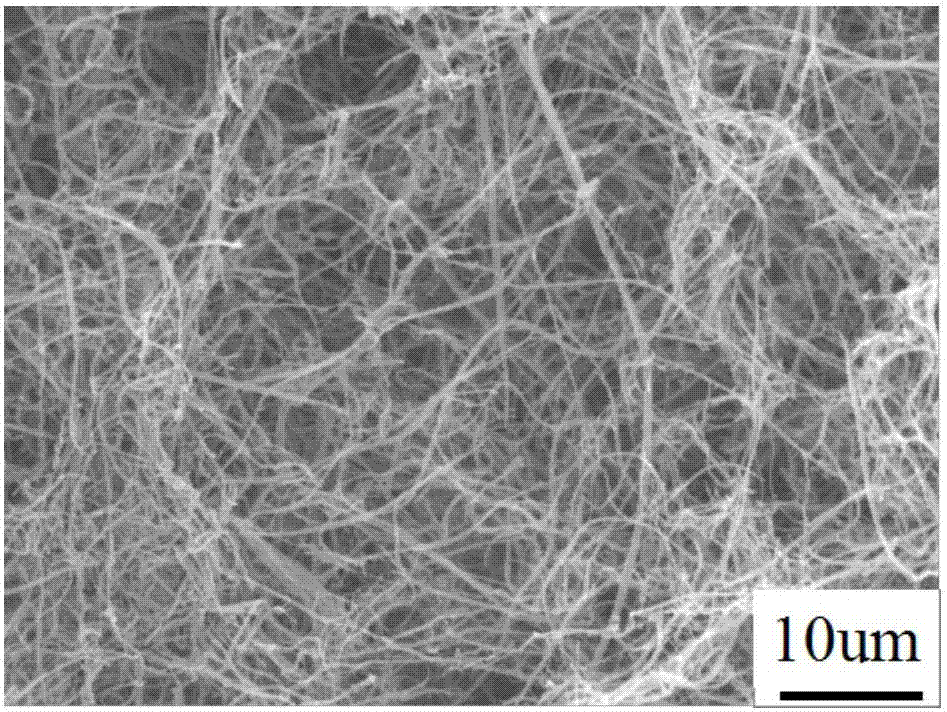

[0027] (1) dispersing ethylene-vinyl alcohol nanofibers with an average diameter of 150nm in deionized water containing tert-butanol, and stirring at a high speed with a high-speed mixer to form a nanofiber suspension;

[0028] (2) put 110g / m 2 The pure cotton spunlace non-woven fabric is completely soaked in the nanofiber suspension in step (1); (3) is frozen at -15°C for 1.5h to solidify, and the solvent is removed by freeze-drying to obtain pure Cotton spunlace / ethylene vinyl alcohol composite filter material.

[0029] The mass fraction of the suspension described therein is 1.1%, and the mass ratio of tert-butanol to deionized water is 60:40. The nanofiber layer gram weight of the composite filter material that is made is 7g / m 2 ; Nanofibers and non-woven fibers are strengthened by physical entanglement, and the performance indicators are shown in Table 1.

Embodiment 2

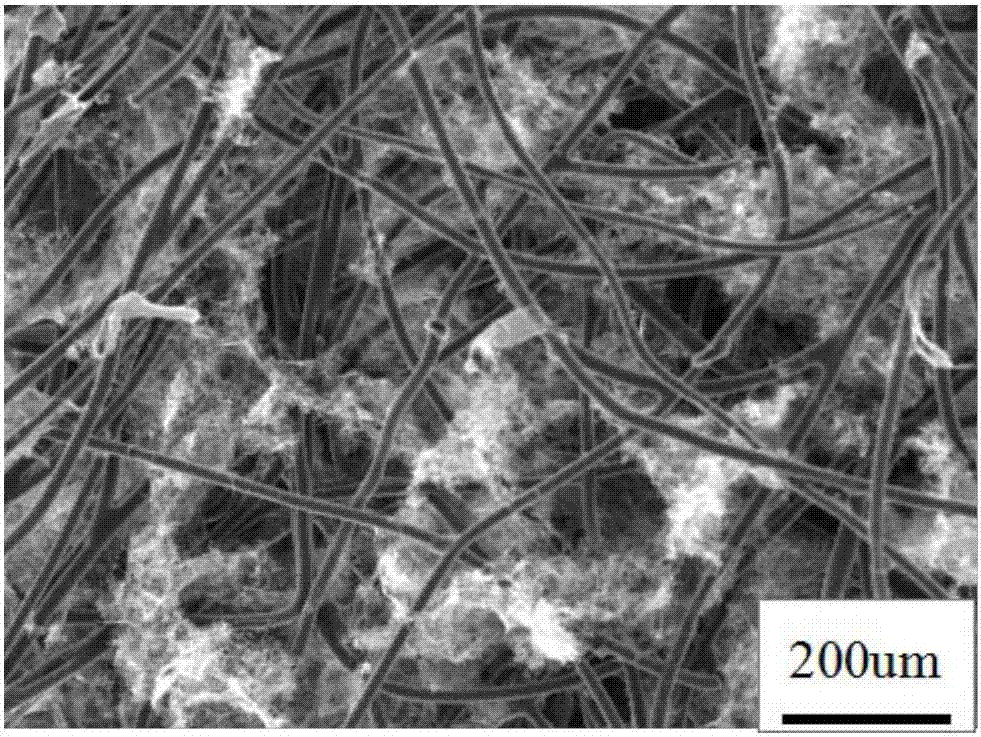

[0033] (1) Nylon 6 nanofibers with an average diameter of 220nm are dispersed in a polyacrylic acid solution containing a mixed solvent of formic acid and ethanol, and a nanofiber suspension is formed through a high-speed mixer;

[0034] (2) Put 130g / m 2 PP needle punched non-woven fabric is completely soaked into the nanofiber nanofiber suspension;

[0035] (3) Freeze at -100°C for 5 hours to make it solidify, and use freeze-drying to remove the solvent, and then dry at 80°C for 5 minutes to chemically cross-link to obtain PP acupuncture / nylon 6 nanofiber composite filter material .

[0036] The mass fraction of the suspension described therein is 0.9%, and the mass ratio of formic acid and ethanol is 25:75. The weight of the nanofiber layer of the composite filter material is 13g / m 2 ; Nanofibers and non-woven fibers are strengthened by physical entanglement and chemical crosslinking, and the performance indicators are shown in Table 1.

Embodiment 3

[0040] (1) The polyethylene terephthalate nanofibers with an average diameter of 170nm are dispersed in a polyvinyl alcohol solution containing methylene chloride and trifluoroacetic acid mixed solvent, and are stirred at a high speed by a high-speed mixer to form a nanofiber suspension, Make it cross-linked at 30°C;

[0041] (2) put 200g / m 2 PP needle punched non-woven fabric is completely soaked into the nanofiber suspension;

[0042] (3) Freeze at -80°C for 4 hours to make it solidify, and use a freeze-drying method to remove the solvent to obtain a PP needle-punched / polyethylene terephthalate nanofiber composite filter material.

[0043] The suspension mass fraction described therein is 0.7%, the mass ratio of dichloromethane and trifluoroacetic acid is 75:25, and the nanofiber layer gram weight of the composite filter material is 11g / m 2 . Nanofibers and nonwoven fibers are strengthened by physical entanglement and physical crosslinking, and the performance indicators ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com