A kind of electret nanofiber filter material and preparation method thereof

A nanofiber and filter material technology, which is applied in the field of electret nanofiber filter material and its preparation, can solve the problems of low filtration efficiency of fine particles and unstable electret performance, and achieve improved electrostatic effect, low production cost, and improved interception The effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

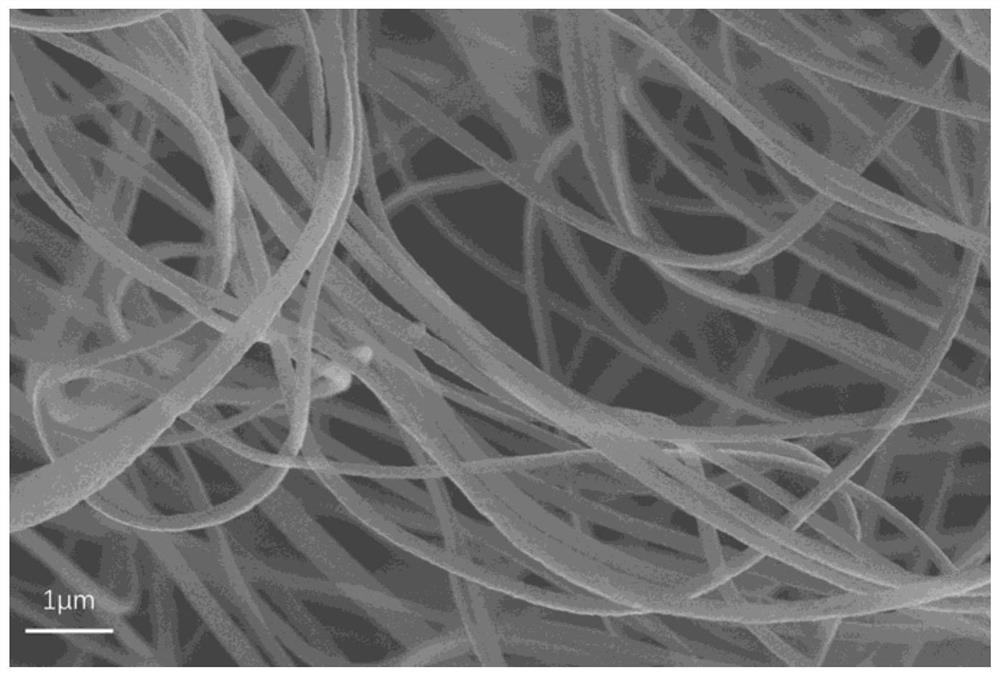

Image

Examples

Embodiment 1

[0032] This Example 1 provides a preferred embodiment of the electret nanofiber filter material, which is prepared by loading a spinning solution on a support material of a PP melt-blown nonwoven fabric by an electrospinning method. Wherein, the spinning solution in this embodiment includes the following components by weight:

[0033] 13 parts polyacrylonitrile (PAN);

[0034] 3 parts methyl 2-aminothiophene-3-carboxylate;

[0035] and 84 parts of N,N-dimethylformamide solvent.

[0036] The present embodiment 1 also provides the preparation method of the above-mentioned materials, which is as follows:

[0037] (1) Weigh 3 parts of methyl 2-aminothiophene-3-carboxylate and add it to a container containing 84 parts of N,N-dimethylformamide solvent, place the container in a water bath at 60°C and heat it, and place the container in a 60°C water bath. The mixture was stirred until dissolved, and then 13 parts of polyacrylonitrile (PAN) were weighed and added to the above-mentio...

Embodiment 2

[0050] This Example 2 provides another preferred embodiment of the electret nanofiber filter material, which is prepared by supporting the spinning solution on a PP spunbond non-woven fabric support material. In this embodiment, the spinning solution includes the following components by weight:

[0051] 15 parts polyvinylidene fluoride (PVDF);

[0052] 4 parts of 5-amino-2thiophenecarboxaldehyde;

[0053] and 81 parts of N,N-dimethylacetamide solvent.

[0054] The present embodiment also provides the preparation method of the above-mentioned materials, as follows:

[0055] (1) Weigh 4 parts of 5-methoxy-2thiophenecarboxaldehyde and add it to a container containing 81 parts of N,N-dimethylacetamide solvent, place the container in a 60°C water bath and heat it, and heat the container. The mixture was stirred until dissolved, and then 15 parts of polyvinylidene fluoride (PVDF) were weighed and added to the above thiophene solution to prepare a uniform and transparent spinning ...

Embodiment 3

[0067] This example provides another preferred embodiment of the electret nanofiber filter material, which is prepared by supporting a spinning solution on a PP melt-blown nonwoven support material, and the spinning solution includes the following components by weight Minute:

[0068] 22 parts polystyrene (PS);

[0069] 3 parts dimethyl 4-aminothiophene-2,3-dicarboxylate;

[0070] and 75 parts of N,N-dimethylacetamide solvent.

[0071] The present embodiment also provides the preparation method of the above-mentioned materials, the details are as follows:

[0072] (1) Weigh 3 parts of dimethyl 4-aminothiophene-2,3-dicarboxylate into a container containing 75 parts of N,N-dimethylacetamide solvent, place the container in a 60°C water bath Heating, stirring the mixture in the container until dissolved, then weighing 22 parts of polystyrene (PS) and adding it to the above-mentioned thiophene solution to prepare a uniform and transparent solution, that is, a spinning solution. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com