Photocatalytic nano composite material as well as preparation method and application thereof

A nanocomposite material and photocatalytic technology, which is applied in the field of photocatalytic nanocomposite materials and its preparation and application, can solve the problems of easy powder agglomeration, poor catalytic performance, and difficulty in separation and recovery, and achieve high degradation efficiency and excellent photocatalysis. The effect of high catalytic stability, reusability and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Example 1 Photocatalytic Nanocomposite BC-TiO 2 - Preparation of RGO

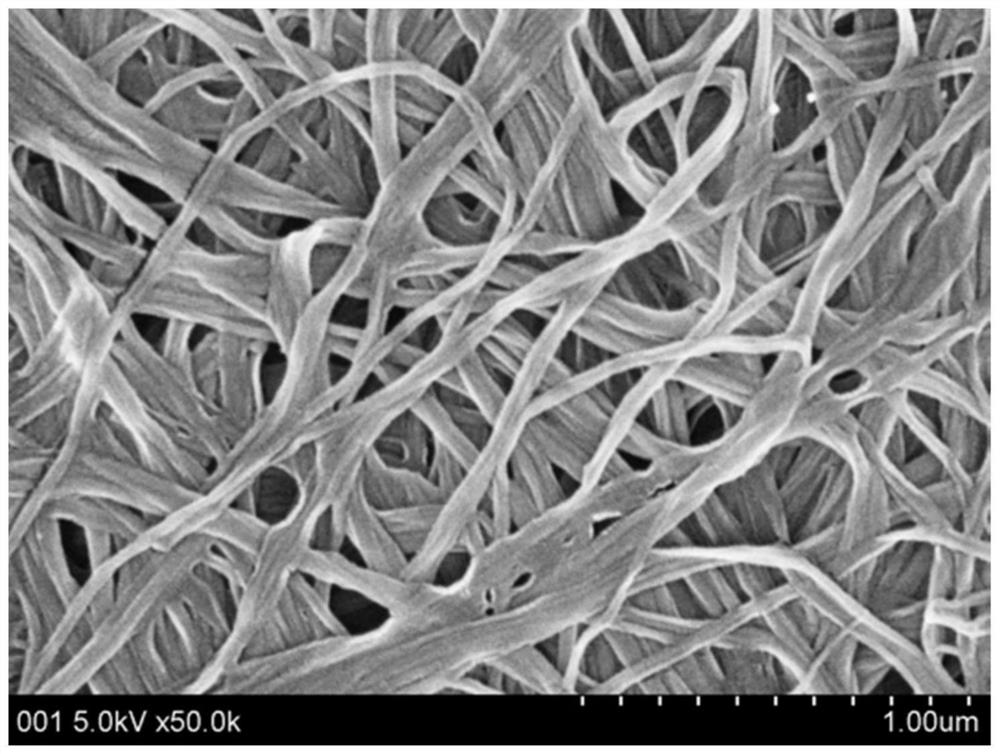

[0067] In this embodiment, bacterial cellulose is added in the form of bacterial cellulose gel film, and its scanning electron microscope picture is shown in figure 1 . In bacterial cellulose, its microstructure is 3D network structure formed by the interweaving of microfibrils, the diameter of microfibrils is 10-100nm; the crystallinity of bacterial cellulose is 79.5%;

[0068] (1) Pretreatment of the bacterial cellulose gel membrane: cut the bacterial cellulose gel membrane into a size of 10cm×10cm, soak in deionized water for 24h, and change the water every 2h. Then put it into an aqueous solution of sodium hydroxide with a concentration of 0.1mol / L and cook for 1 hour at a temperature of 100°C, wash it with deionized water until the cleaning solution is neutral, then dry it in an oven at 40°C for 2 hours, and then Transfer to a vacuum drying oven and dry at 50°C for 10 hours to obtain a bacter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com