A kind of preparation method of superfine fiber non-woven filter material

A technology of ultra-fine fiber and filter materials, which is applied in the direction of non-woven fabrics, separation methods, filtration and separation, etc., can solve the problems of shrinking fibers and not being able to proceed smoothly, and achieve high filtration efficiency and excellent filtration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

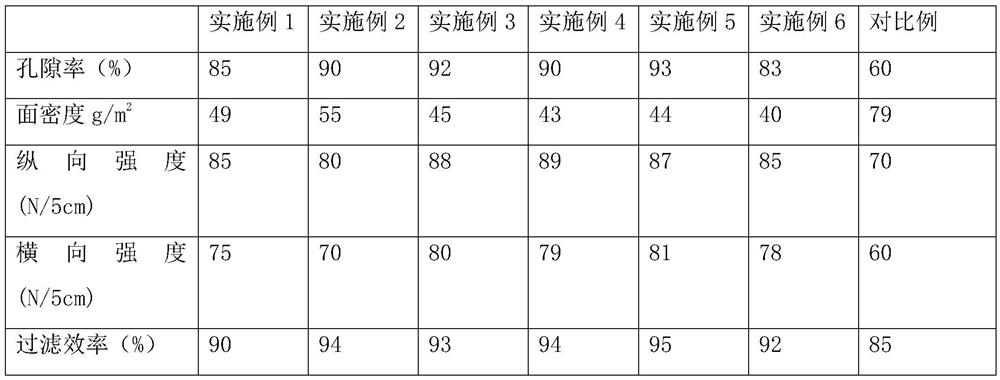

Examples

Embodiment 1

[0032] A preparation method of superfine fiber non-woven filter material, comprising the steps of:

[0033] Step 1) Preparation of magnetic stress polymer slices, the magnetic stress particles are ferric oxide, the particle size is 500nm, the magnetic stress particles and the first polymer are mixed in a ratio of 11:100 and then granulated to obtain Magnetically stressed polymer slices containing magnetically stressed particles;

[0034] Step 2) Preparation of superfine fiber spun silk, the magnetic stress polymer chips prepared in step 1) are transported to the first screw extruder through the hopper, and melted in the first screw extruder to obtain the first polymer Melt; the second polymer is transported to the second screw extruder through the hopper, and melted in the second screw extruder to obtain the second polymer melt; the first polymer melt and the second polymer melt The distribution is delivered to the two-component spinning assembly through a metering pump, and th...

Embodiment 2

[0039] After the magnetic force splitting in step 2), the step of impacting with external force, that is, impacting with airflow is also included, and other parameters are the same as those in Embodiment 1.

Embodiment 3

[0041] Adjust the particle size of the magnetic stress particles to 600nm, mix the magnetic stress particles with the first polymer at a ratio of 15:100, adjust the solubility parameter ratio of the first polymer to the second polymer to 1:15, The strain ratio is 1:2, the spinneret hole structure is adjusted to a ten-lobe orange segment shape, and other process parameters are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com